an underground pipeline system

An underground pipeline and pipeline technology, applied in tunnel systems, roads, tracks, etc., can solve the problem of large occupied space, and achieve the effect of increasing the cargo volume, large space, and releasing above-ground space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

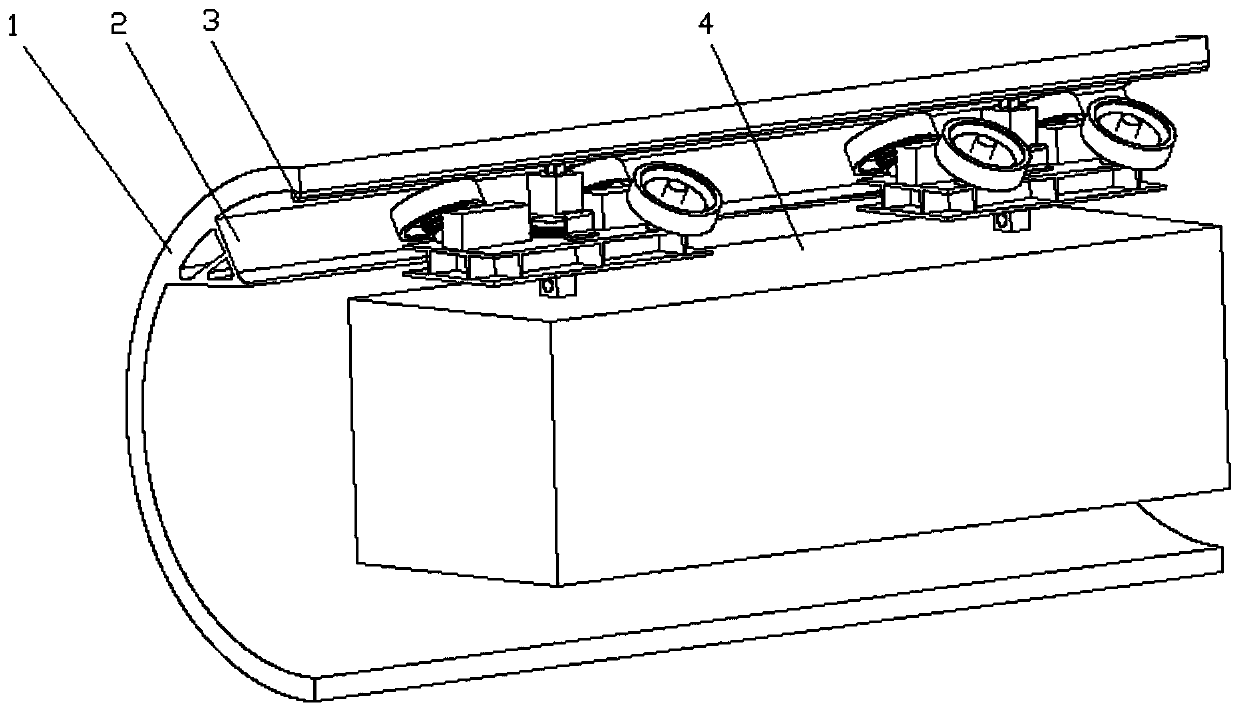

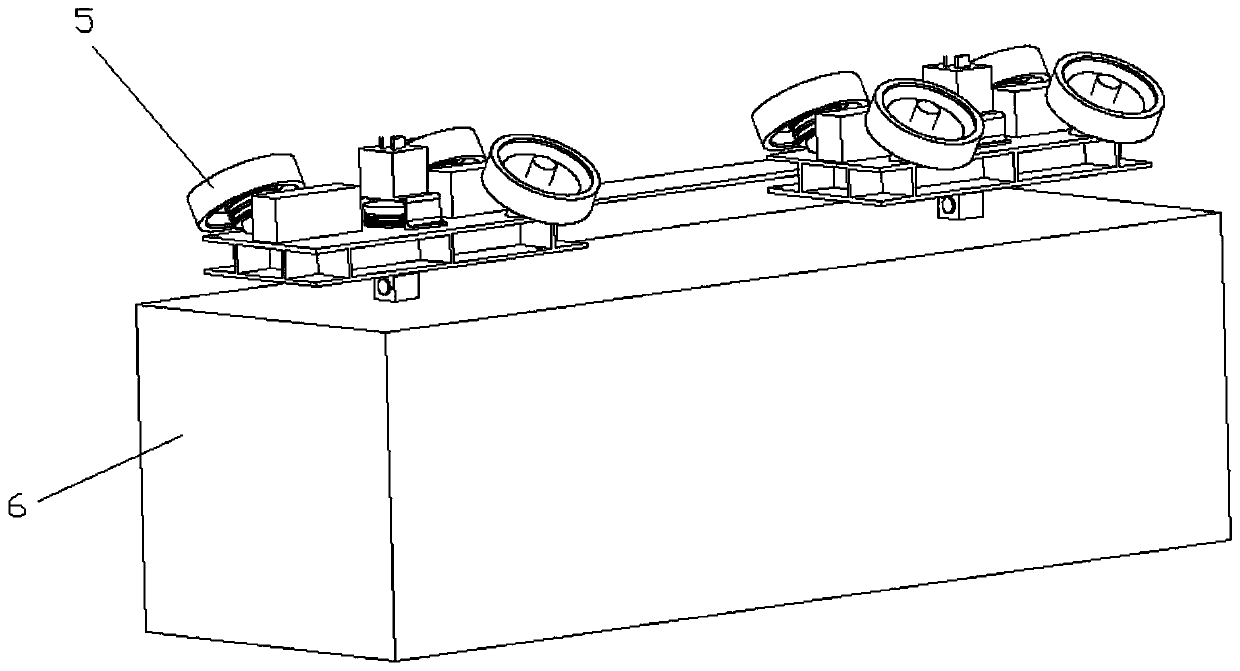

[0044] The material of the pipe 1 is steel or concrete, and the cross section is circular; a running rail group is set inside the circular pipe 1. At this time, the running rail group includes: the first running rail and the second running rail, about the center of the circular pipe 1 Line symmetry, the material of the first running rail and the second running rail is steel; the first running rail and the second running rail are fixed on the pipeline 1 by fasteners or welding, or, the first running rail and the second running rail are connected with the The pipeline 1 is made by integral molding. Since the logistics transport vehicle 4 itself has a certain weight, when it is fully loaded with goods for transportation, the structural requirements for the running rail 2 and the pipeline 1 are relatively high. The overall strength of the steel pipeline 1 and the running rail 2 And high rigidity, can meet the suspension and transportation requirements of the logistics transport veh...

Embodiment 2

[0050] See attached Figure 10 , the material of the pipeline 1 is steel or concrete, and the cross-section is oval; two running rail groups are arranged in the oval pipeline 1, one of which includes: the third running rail 20 and the fourth running rail, and the other running rail group Including: the fifth running track and the sixth running track 21. The third running rail 20 and the sixth running rail 21 are symmetrically arranged on both sides of the top of the oval pipe 1, the fourth running rail and the fifth running rail are fixed in the middle of the top of the oval pipe 1, the fourth running rail and the fifth running rail The rails can be arranged independently, or the fourth running rail and the fifth running rail can be made as a whole. The material of the running rail set in this embodiment and the connection method with the pipeline 1 are the same as those in the first embodiment. Setting two running rail groups can realize the side-by-side operation of the lo...

Embodiment 1

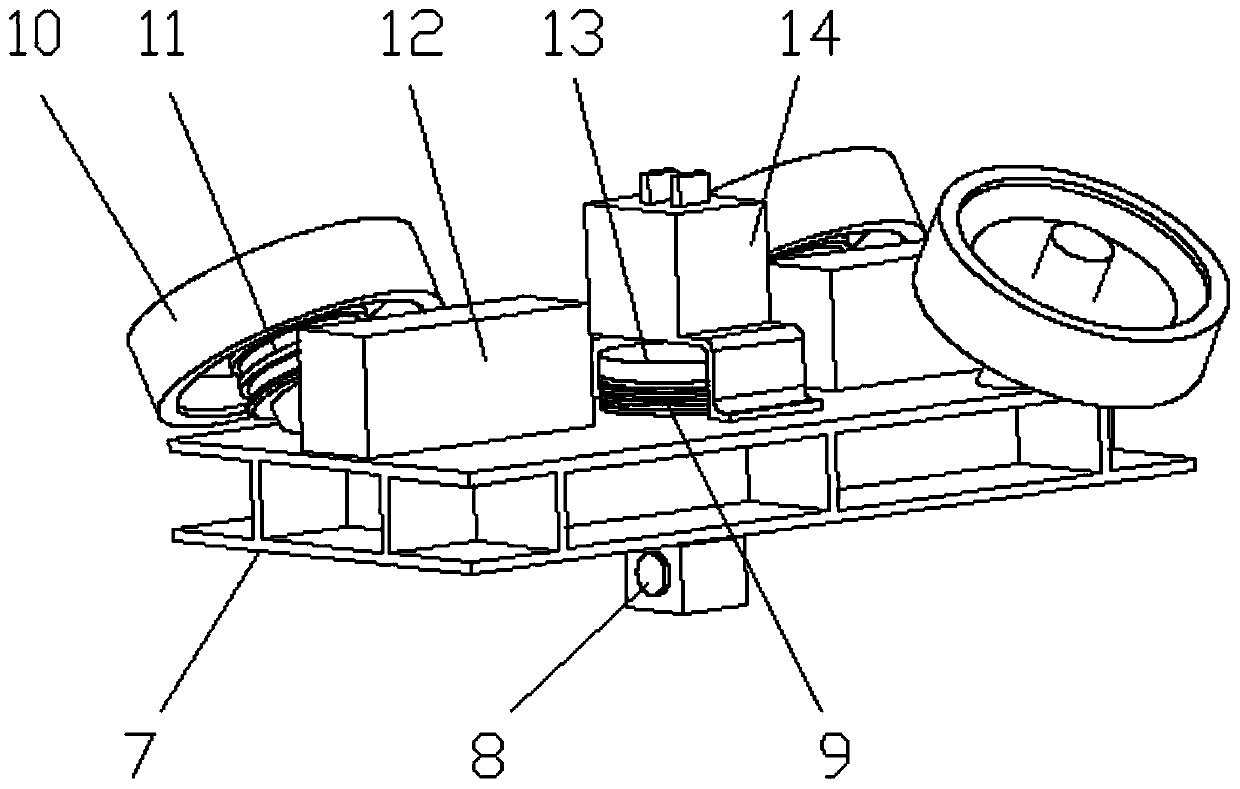

[0059] See attached image 3 and 4 , the bogie 5 includes: frame 7, suspension pin 13, bearing pin 8, some in-wheel motors 11 and some wheels 10; Set in the shaft hole for hanging the car body 6; several in-wheel motors 11 are symmetrically arranged on both sides of the top of the frame 7 relative to the center line of the frame 7; the in-wheel motors 11 are fixedly connected to the frame 7; several wheels 10 are arranged on the corresponding in-wheel motor 11 output end; the radial section of the wheel 10 is perpendicular to the rail surface 18 of the running rail 2.

[0060] The wheels 10 on both sides of the bogie 5 are arranged in a figure-eight shape. The weight of the car body 6 is transmitted to the two running rails 2 through the pin shaft 8, the suspension pin 13, the frame 7, the hub motor 11 and the wheels 10. The car body 6 passes the curve During the road section, under the action of centrifugal force, the wheels 10 on one side of the frame 7 rise along the incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com