Polished rod sealer facilitating taking out sealing element for oil pumping well

A polished rod sealer and seal technology, which is used in sealing/isolation, earthwork drilling, wellbore/well components, etc., can solve the problems of long downtime, increased workover costs, and difficulty in removing old seals. The effect of high success rate of well opening, reduction of workover costs and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

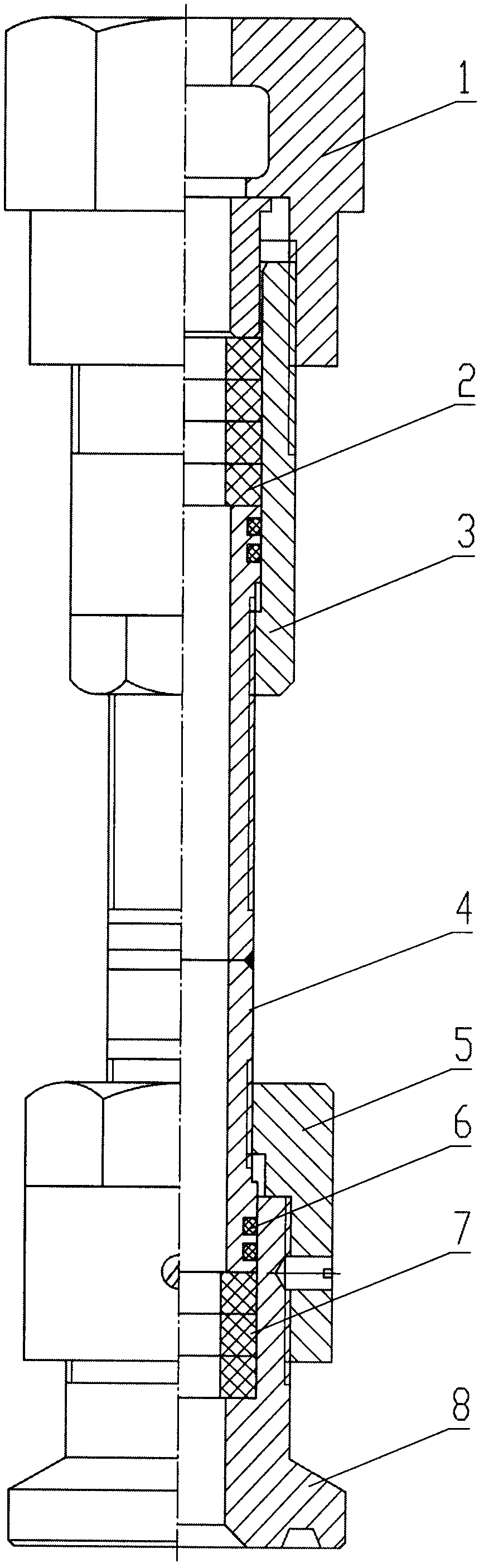

[0008] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0009] As can be seen from the figure, the embodiment of the present invention includes an adjustment cap 1, a sealing member 2, a sealing box 3, a support pipe 4, a connecting sleeve 5, a sealing ring 6, a blowout-proof sealing member 7, and a connecting head 8. The sealing member 2 is installed on the sealing Inside the box 3, the thread of the adjusting cap 1 is screwed with the thread of the sealing box 3, the end of the support tube 4 is in the sealing box 3, the seal 2 sits on the upper end surface of the support tube 4, and the sealing can be adjusted by rotating the adjusting cap 1 The tightness of part 2, the upper thread of support pipe 4 is a left-handed thread, the lower thread of sealing box 3 is a left-handed thread, and the upper thread of support pipe 4 matches the lower thread of sealing box 3 and is screwed together.

[0010] In order not to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com