Multiphase medium plugging device and method for gas extraction drill hole

A gas drainage and plugging device technology, which is applied in the direction of gas discharge, safety devices, mining equipment, etc., can solve the problems of long sealing section length, low concentration and limitation of gas drainage, so as to improve the sealing effect and improve The effect of extraction concentration, wide availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

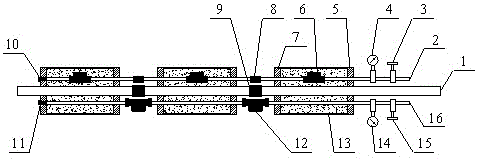

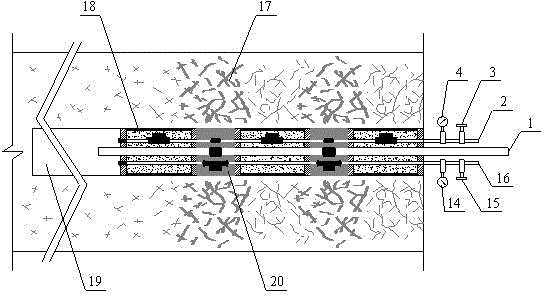

[0019] The gas drainage drilling multiphase medium plugging device of the present invention is mainly composed of a plurality of gas drainage pipes 1, a mortar filling pipe 2, an elastic capsule 13, and a mucus filling pipe 16. A 9-phase connector is connected, figure 1 There are three of them, each gas drainage pipe 1 is respectively provided with an elastic capsule 13, and each elastic capsule 13 is processed with acupuncture micro-holes. The two ends of each elastic capsule 13 are respectively provided with the left baffle plate 7 and the right baffle plate 5 which fix it, and the upper and lower sides of a plurality of gas extraction pipes 1 are respectively provided with the same number of holes which pass through the elastic capsule 13. A plurality of mortar filling pipes 2 and mucus filling pipes 16, a plurality of mortar filling pipes 2 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com