idler gear assembly for generator

A generator and idler technology, applied in the field of two-piece idler assembly, can solve the problems of uneven wear and replacement of gear teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

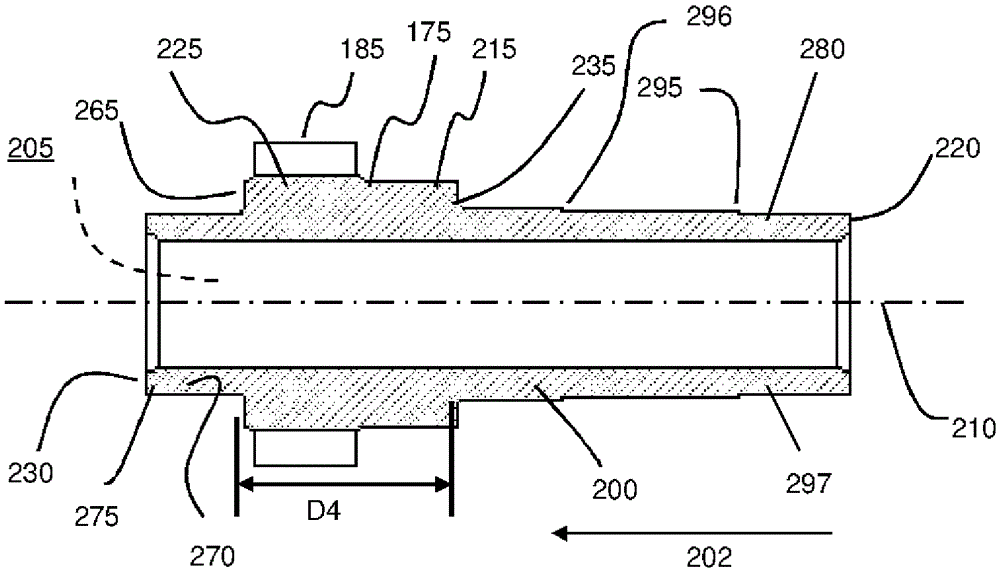

[0014] An embodiment of an idler gear assembly includes a first gear coupled to a second gear in a gear train of a generator. The first gear includes a first shaft including a first dimension received in a complementary circular bore of the second gear. The complementary circular hole has a second dimension for causing an interference lock between the first gear and the second gear. Additionally, the drive tab on the second shaft of the second gear is configured to be received in a complementary hole or slot on the shoulder of the first shaft to reinforce the connection between the first and second gears and The first gear is prevented from slipping out of frictional contact with the second gear and the second gear is prevented from rotating relative to the first gear.

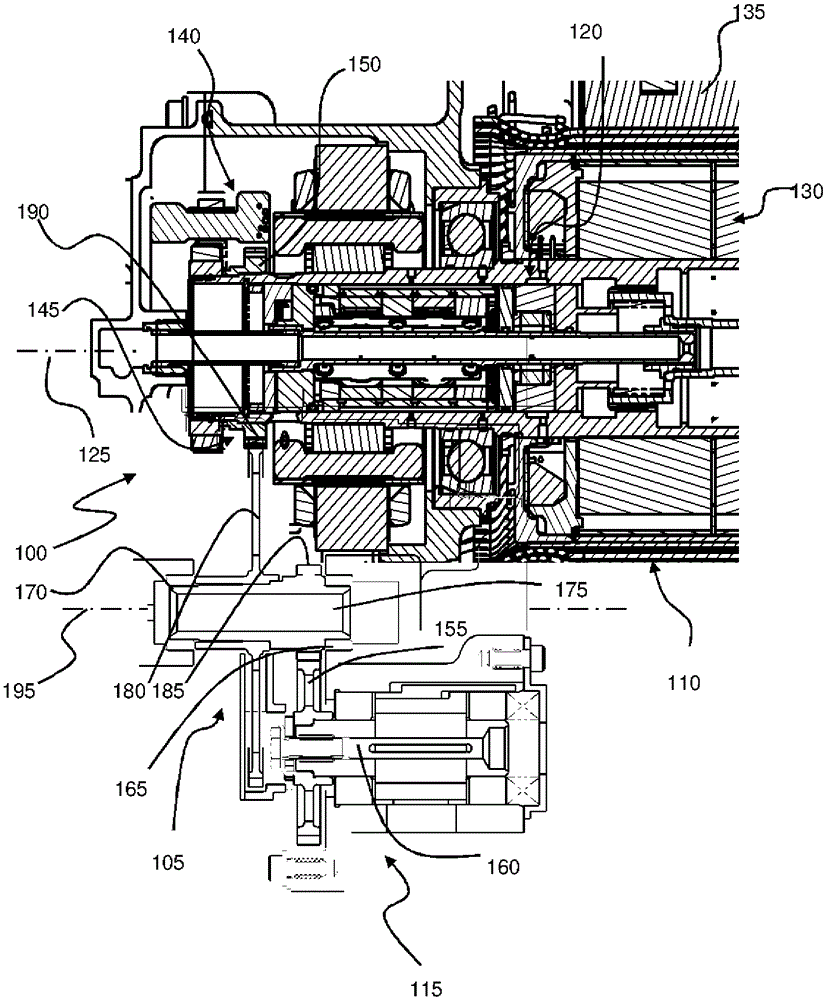

[0015] With reference to the accompanying drawings, figure 1 An example generator 100 is shown that includes a two-piece idler assembly 105 in accordance with an embodiment of the invention. In particular, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com