Automatic discharge device of calcium carbide furnace

A furnace device, calcium carbide furnace technology, applied in furnaces, furnace components, charge control, etc., can solve problems such as failure to meet the use requirements of calcium carbide furnaces, difficulty in passing molten calcium carbide, difficulty in controlling the depth of blockage, etc., to achieve normal operation of the furnace mouth, Reduce adverse effects and block eyesight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

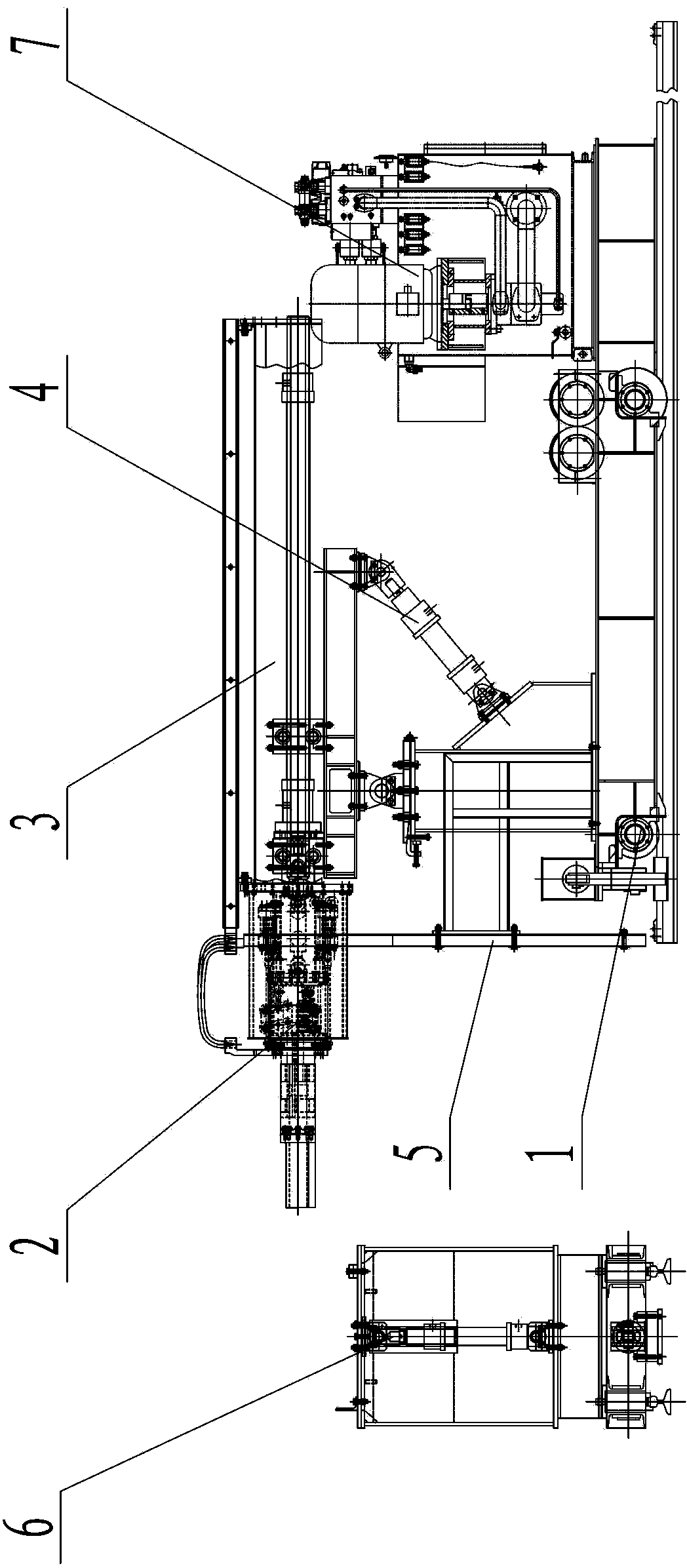

[0034] Such as figure 1 The automatic furnace discharge device of a calcium carbide furnace shown is composed of a cart mechanism 1, a tool lever locking mechanism 2, a working arm mechanism 3, a working arm tilting mechanism 4, a heat insulation protection system 5, a tool cart 6 and a calcium carbide furnace for controlling The on-board hydraulic station 7 of the hydraulic equipment in the automatic furnace discharge device and the automatic control system 8 for the structural cooperation of the various parts of the calcium carbide furnace automatic furnace discharge device are composed; wherein the tool lever locking mechanism 2 and the working arm mechanism 3 are connected together by bolts, The working arm mechanism 3 is fixed to the upper part of the cart mechanism 1 by bolts. The two ends of the working arm tilt mechanism 4 are respectively connected with the cart mechanism 1 and the working arm mechanism 3 by bolts. The heat insulation protection system 5 is fixed at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com