Depth gauge checking tool

A depth and ejector technology, which is applied in the field of measuring instruments, can solve the problems of unsuitable mass production of workpieces, complex measurement process, time-consuming and other problems, and achieve the effect of simple detection, guaranteed measurement accuracy and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

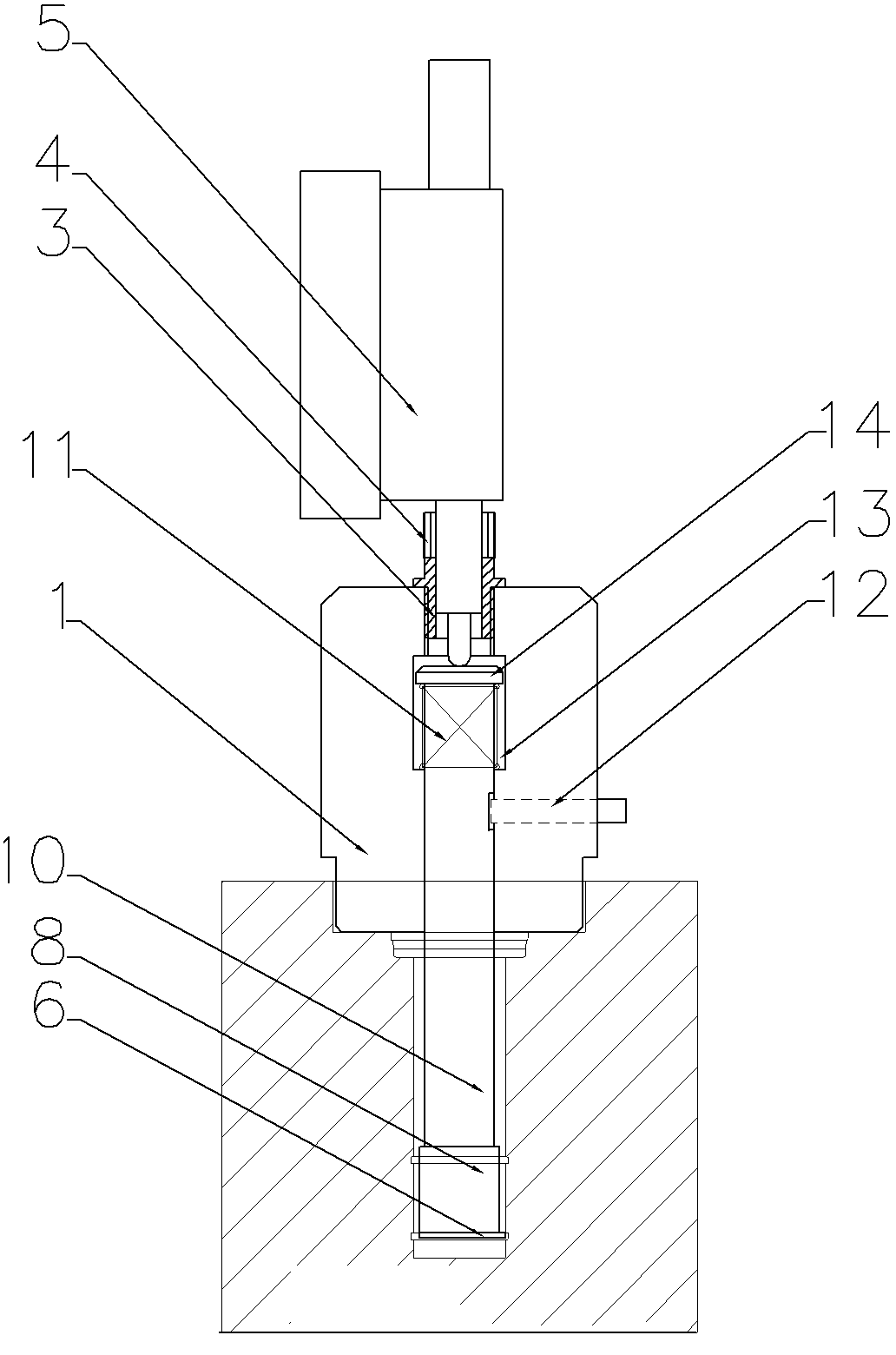

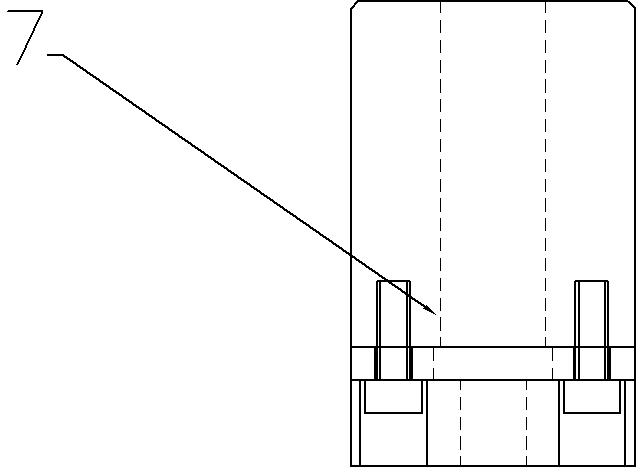

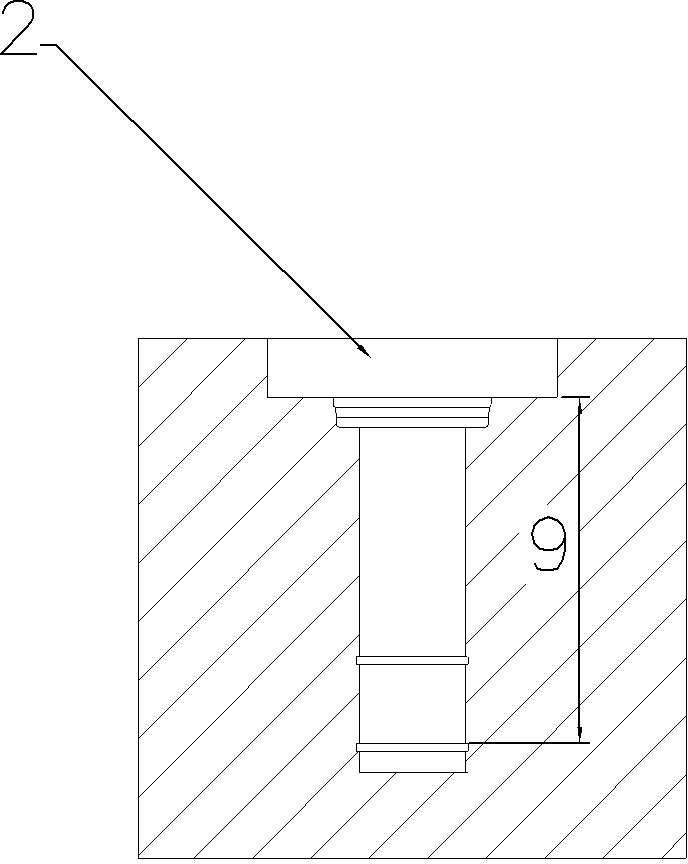

[0014] See Figure 1 to Figure 3 , a depth gauge inspection tool, which includes a dial indicator 5 and a calibration block 7, which includes a measuring body 1, a clamping device and a push rod 10, the measuring body 1 is installed on the step surface of the part to be measured 2, and the center of the measuring body 1 has a In the guide hole, the dial indicator 5 is inserted into the clamping device and fixed at the end of the guide hole of the measuring body 1, the ejector rod 10 is installed in the guide hole, the bottom of the ejector rod is rigidly connected with the measuring block 8, and the bottom of the measuring block 8 is rigidly connected with Measuring piece 6, one end of measuring piece 6 protrudes from the contour of the bottom end of the ejector rod 10; the middle part of the guide hole is separated from the limiting hole 13, and the top of the ejector rod 10 is provided with a limiting surface 14, which is located at the bottom of the limiting surface 14 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com