Automatic test device for sample processing for determination of lead in tinplate coating

A technology for sample processing and automatic testing, which is applied in the preparation of test samples, electrochemical variables of materials, etc., can solve the problems of lead migration, complex sample preparation, affecting measurement accuracy, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

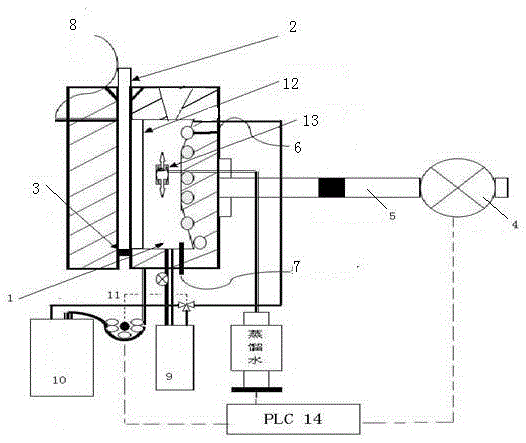

[0018] Such as figure 1 Shown, the present invention a kind of lead determination sample processing automatic test device in tinplate coating, it comprises:

[0019] An electrolytic cell 1, which is an open container, contains a stripping solution and is equipped with a tinplate 2 to be measured;

[0020] A sealing ring 12, which is nested in the electrolytic cell 1, and is in contact with the surface of the tinned plate to be tested 2; the lower part of the tinned plate to be tested 2 is also provided with a positioning rod 3;

[0021] A pneumatic sealing mechanism, which includes a pneumatic valve 4 and a closed actuator rod 5 for sealing the sealing ring and the tin plate to be tested;

[0022] A set of electrodes, with platinum wire wound inside the electrolytic cell as the working electrode 6, a silver electrode or calomel electrode 7 inserted into the electrolytic cell 1 as the reference electrode, and a retractable titanium alloy needle connected to the tinned plate 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com