Electric Motor Load Tracking Synchronous Adjustment Power Saving Device

A technology of load tracking and synchronous adjustment, applied in AC motor control, motor control in four quadrants, electrical components, etc., can solve the problems of slow detection rate and response speed of high-power motors, and achieve high efficiency and strong anti-interference. , the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

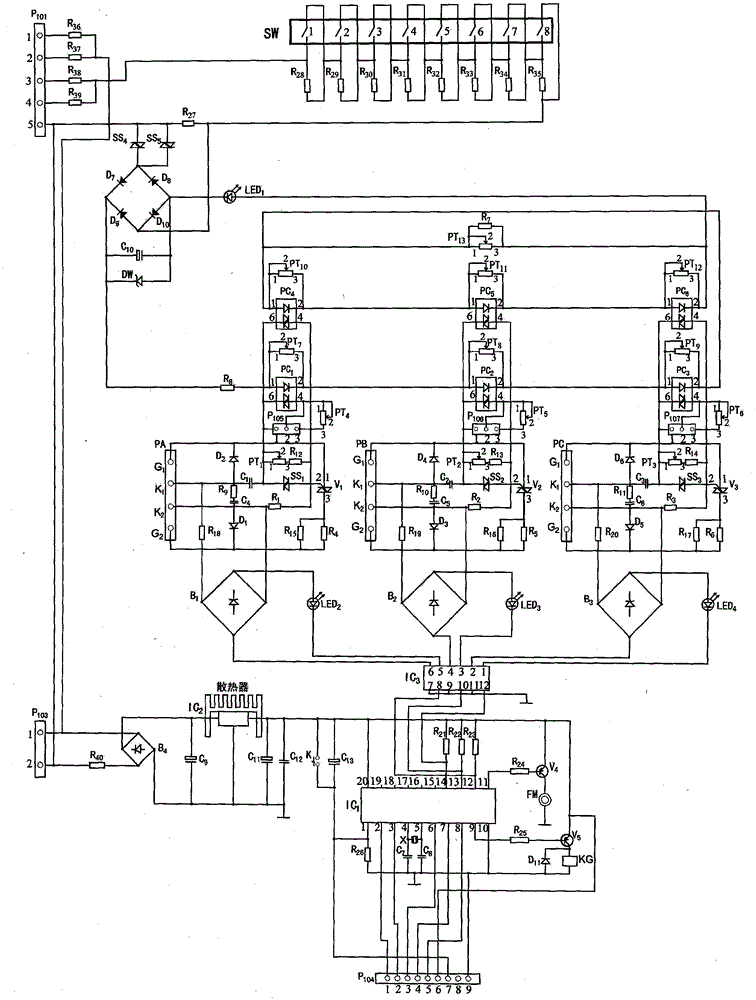

[0011] in figure 1 Middle, connector terminal P 101 Pin 1 and resistance R 36 One end connected, plug terminal P 101 Pin 2 and resistance R 37 One end connected, resistance R 36 The other end, resistance R 37 The other end, connector terminal P 103 Pin 1 with full bridge rectifier B 4 The input end is connected. Connector terminal P 101 3 feet and resistance R 38 One end connected, plug terminal P 101 4 feet and resistance R 39 One end connected, resistance R 38 The other end, resistance R 39 The other end, resistance R 28 One end and eight gear switch SW 1 One end connected, eight-speed switch SW 1 The other end, resistance R 28 The other end, resistance R 29 One end and eight gear switch SW 2 One end connected, eight-speed switch SW 2 The other end, resistance R 29 The other end, resistance R 30 One end and eight gear switch SW 3 One end connected, eight-speed switch SW 3 The other end, resistance R 30 The other end, resistance R 31 One end and eight gear switch SW 4 One end con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com