Fish killing machine

A fish killing machine and frame technology, applied in fish processing, slaughtering, food science, etc., can solve the problems of easy frostbite or other diseases, unfavorable physical and mental health of workers, and high labor intensity of workers, and achieves easy implementation, simple structure, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

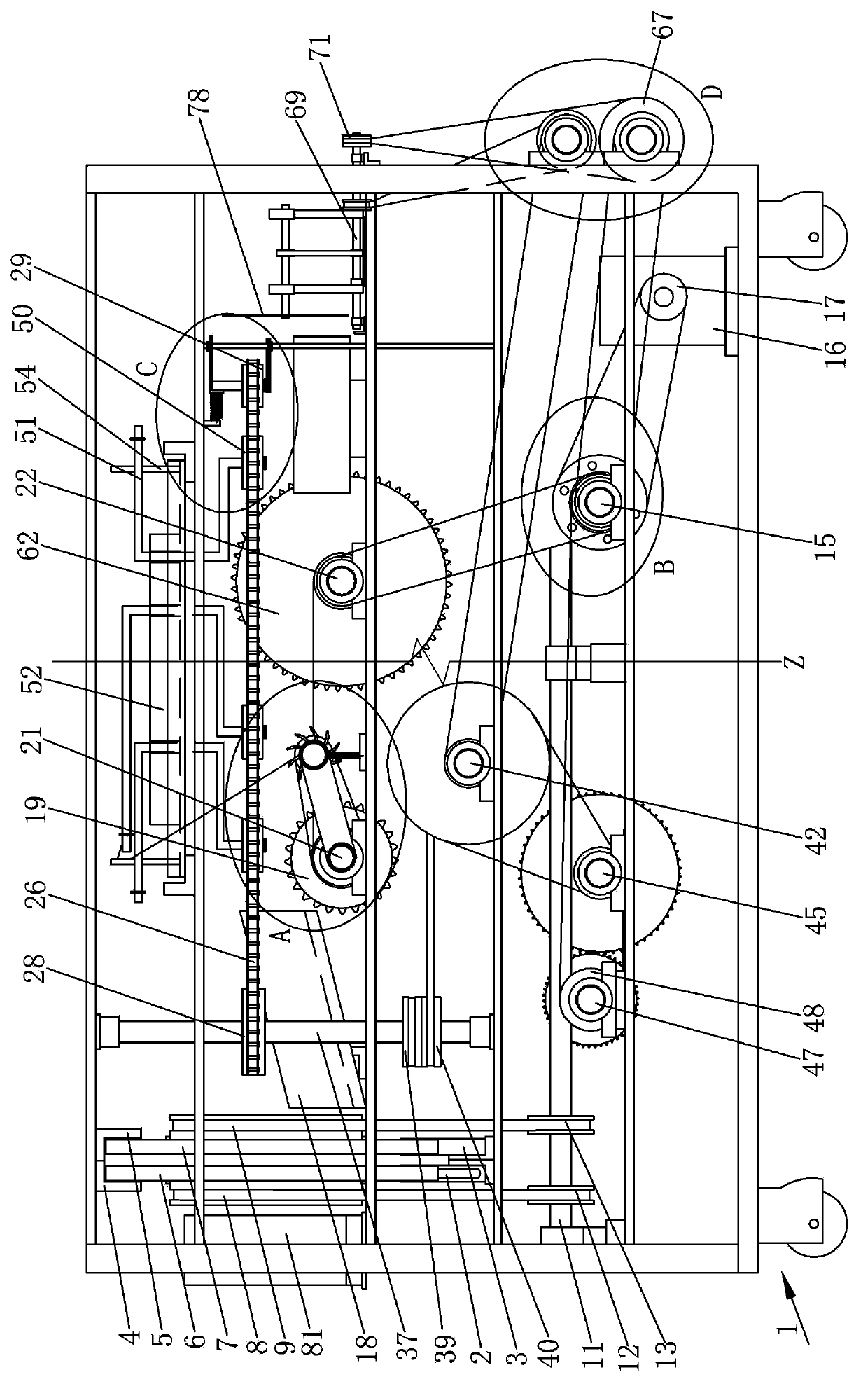

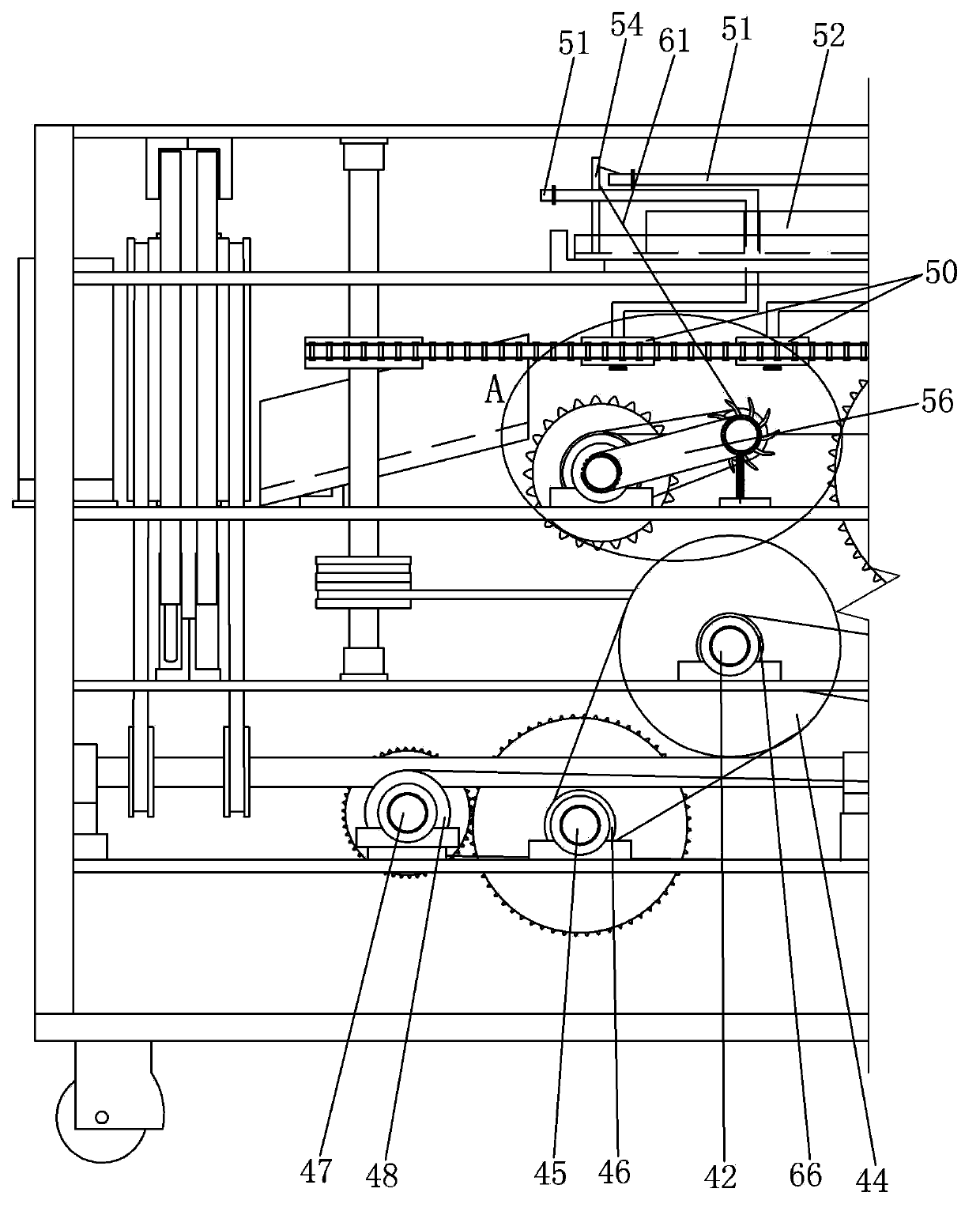

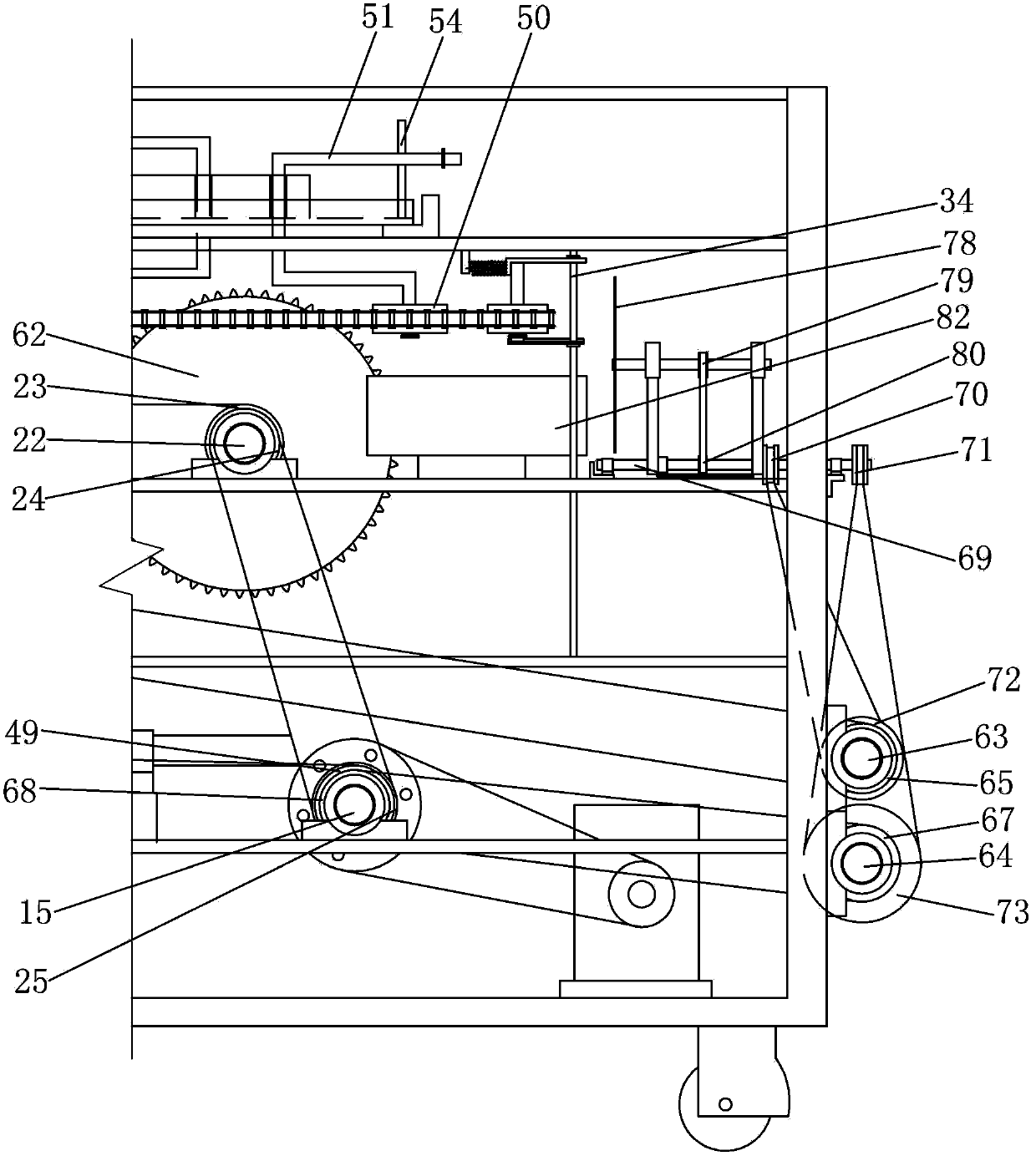

[0054] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0055] Such as Figures 1 to 9 As shown, a fish killing machine includes a frame 1, and the frame 1 is a rectangular parallelepiped frame structure. The left end of described frame 1 is provided with descaling assembly, and this descaling assembly mainly consists of left support block 2, right support block 3, left limit beam 4, right limit beam 5, left swing block 6, right swing block 7 , Left runner 8, right runner 9, leaf spring 10 and descaling transmission mechanism constitute. Wherein, the left supporting block 2 and the right supporting block 3 are all fixed on the middle part of the left end of the frame 1, and the left supporting block 2 and the right supporting block 3 are arranged side by side.

[0056] The left spacer beam 4 is provided directly above the left support block 2, and the right spacer beam 5 is provided directly above the right supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com