Nut shell breaking machine

A nut crushing and shelling machine technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of difficult control of force, low work efficiency, and slow speed of artificial shell crushing, and achieves high production efficiency, simple structure, and light weight. Effect of Small Machine Space Volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

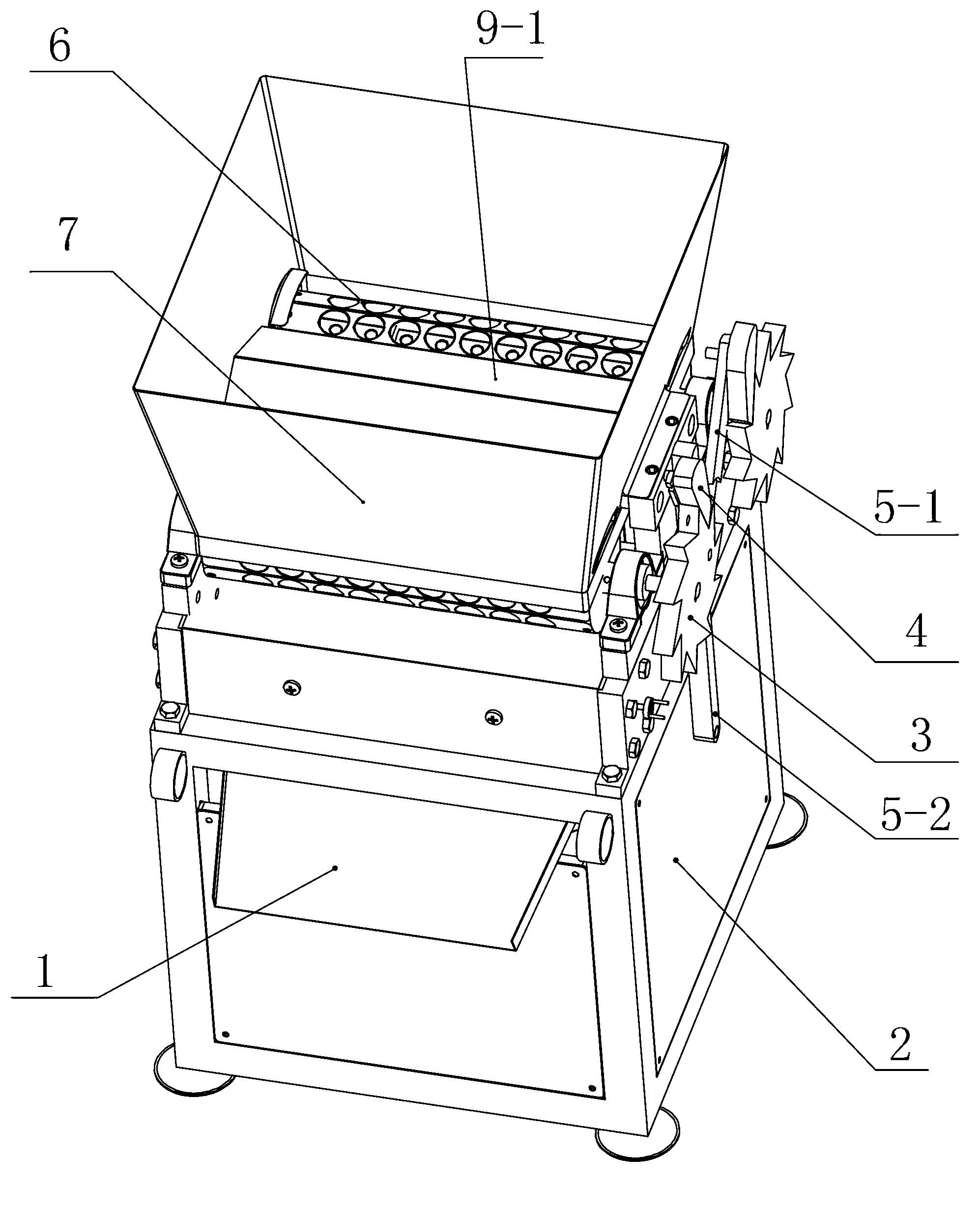

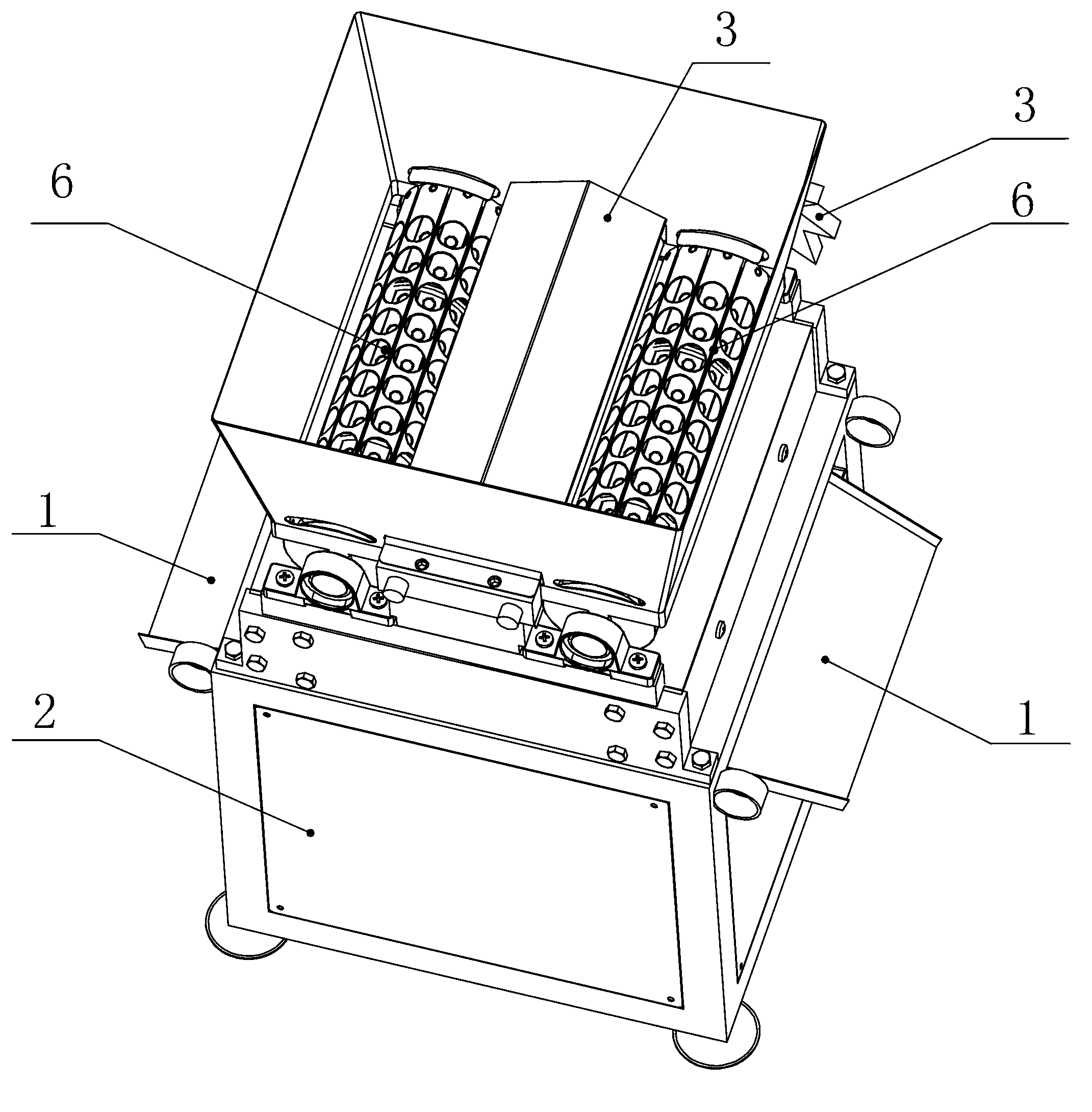

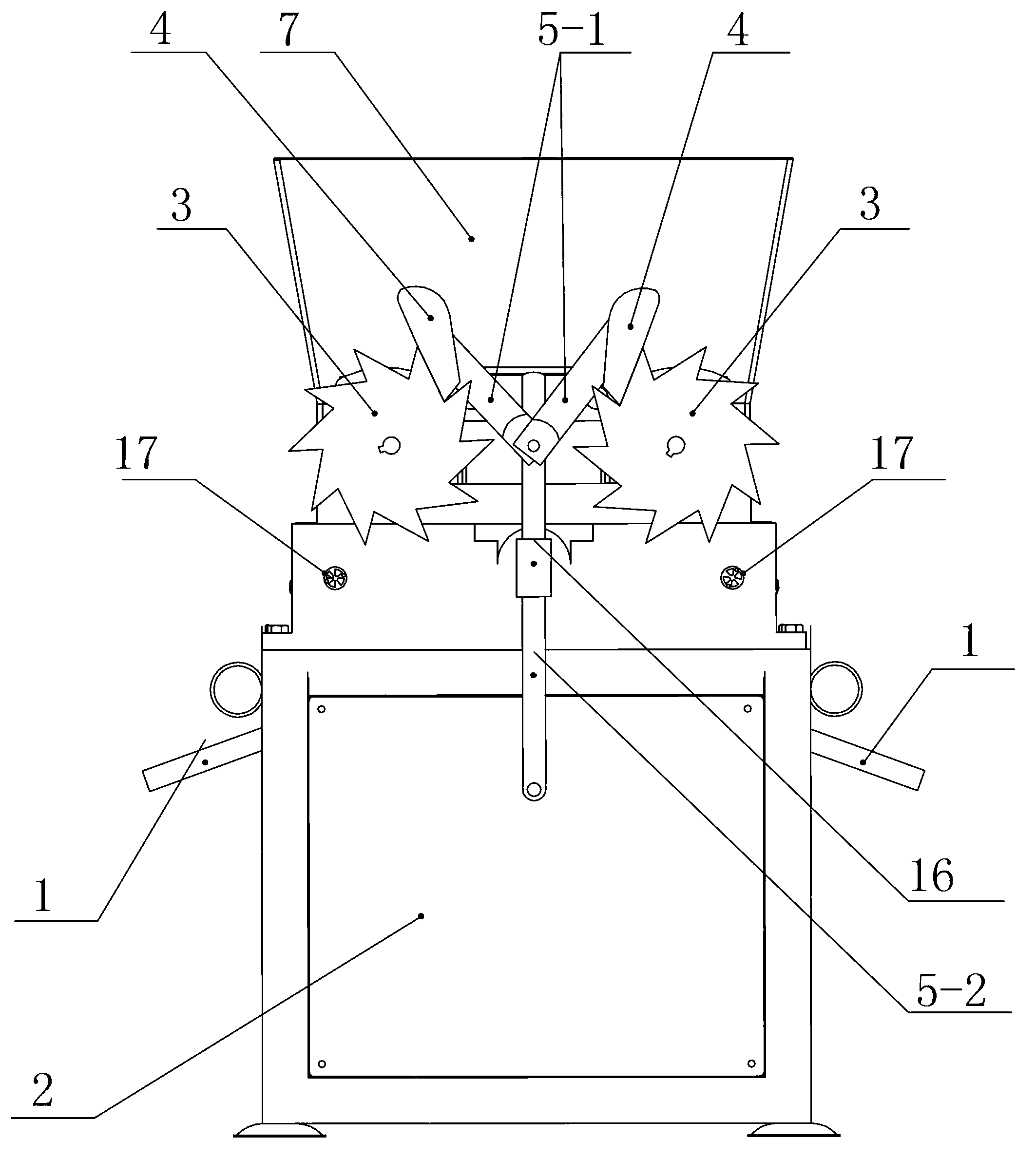

[0033] like Figure 1-4 As shown, a nut sheller according to the present invention includes a vertically arranged frame 2, a feed hopper 7 located on the frame, and two discharge ports 1 distributed on the left and right sides of the frame. The shell crusher is also provided with a feeding device and a pinching device.

[0034] The feeding device includes two rotatable feeding rollers 6 distributed on the left and right sides of the bottom end of the feeding hopper (the feeding rollers are installed on the feeding roller fixing frame 8), a ratchet pawl mechanism and a power mechanism for driving the feeding rollers to rotate intermittently. . The two feed rollers are arranged horizontally and symmetrically, and their rotating shafts extend along the front-to-back direction; on the cylindrical surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com