Fault positioning and marking method of digital flat-panel type X-ray detection system

A digital flat panel and positioning mark technology, which is applied in the direction of using radiation for material analysis, etc., to achieve the effects of strong applicability, improved positioning accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

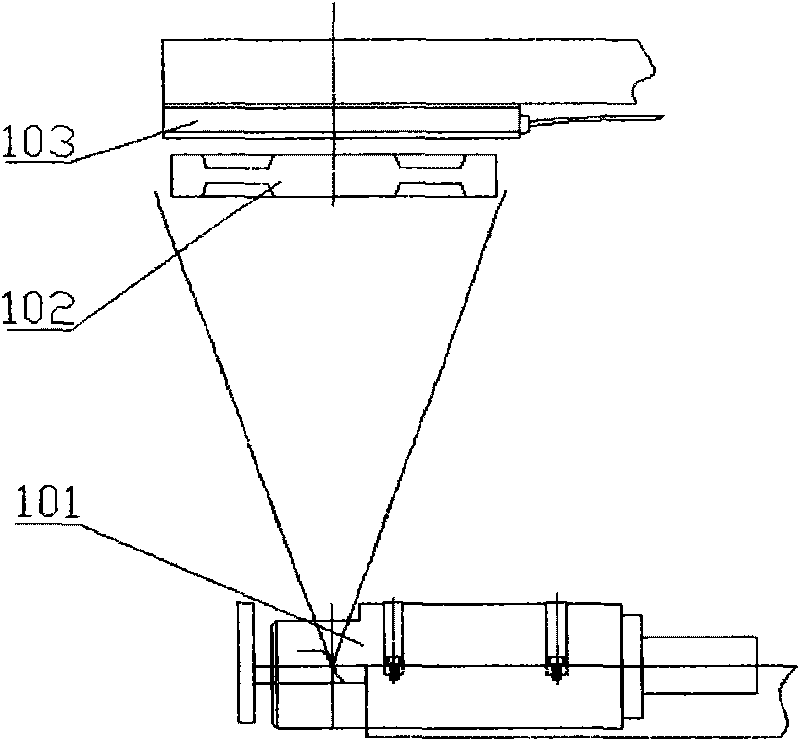

[0016] The defect positioning and marking method of the digital flat-panel X-ray inspection system is described with reference to the accompanying drawings.

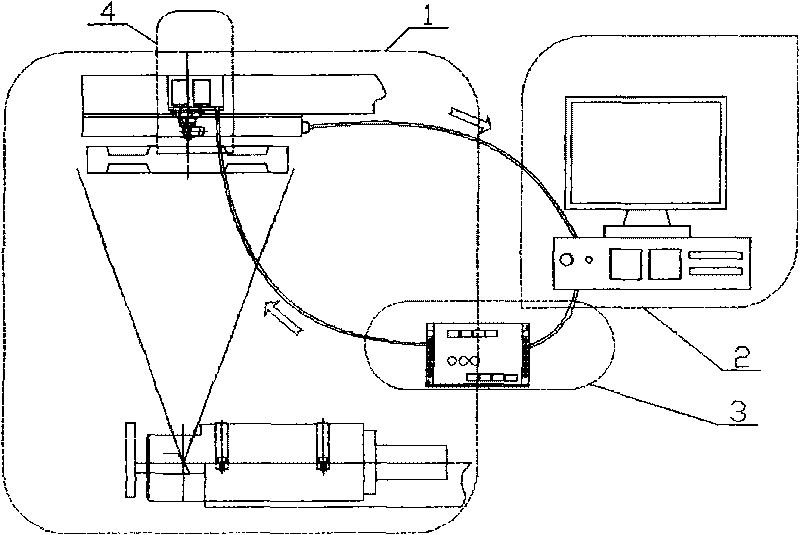

[0017] (1) System positioning marking device connection and signal connection: This method consists of existing digital flat panel X-ray real-time imaging device 1, defect location computer display device 2, system conversion control device 3 and automatic positioning and aiming injection device 4. The signals of each device are sequentially connected and transmitted: the output signal of the digital flat-panel X-ray real-time imaging device is connected to the defect positioning computer display device, the signal output and input of the defect positioning computer display device is connected to the system conversion control device, and the system conversion control device is connected to the automatic positioning and aiming injection device.

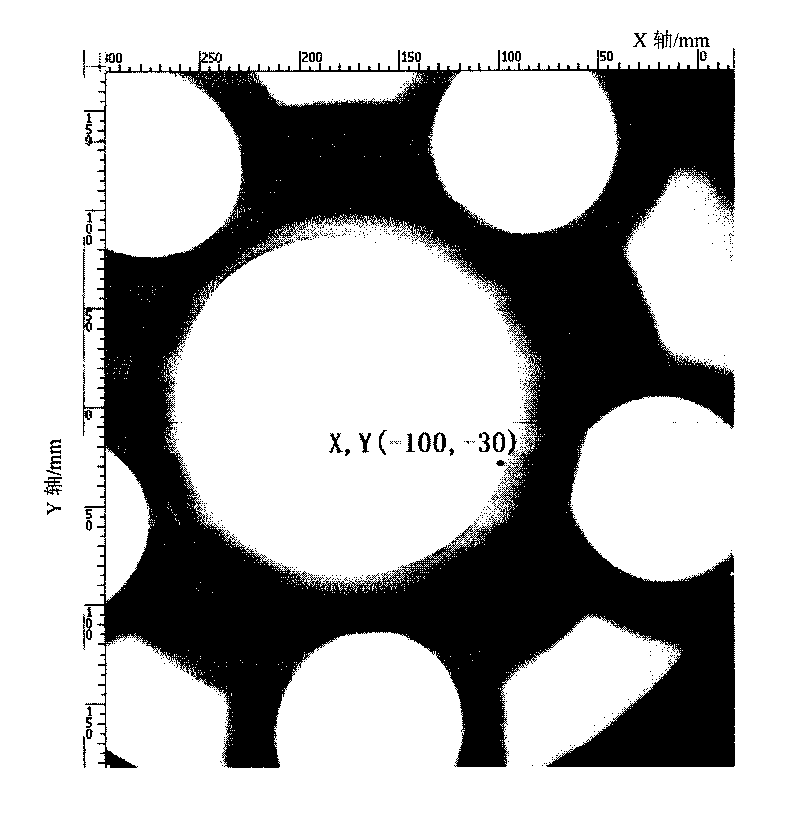

[0018] (2) Acquisition of defect signals: in the digital flat-panel X-ray rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com