Humidifying system of bulk curing barn

A technology of intensive drying room and humidity control, applied in the field of humidity control system of dense drying room, can solve the problems such as the humidity of the drying room cannot be adjusted in time, the humidity cannot be too high, and the drying effect of tobacco leaves is affected, so as to achieve a good drying effect. , the effect of avoiding energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

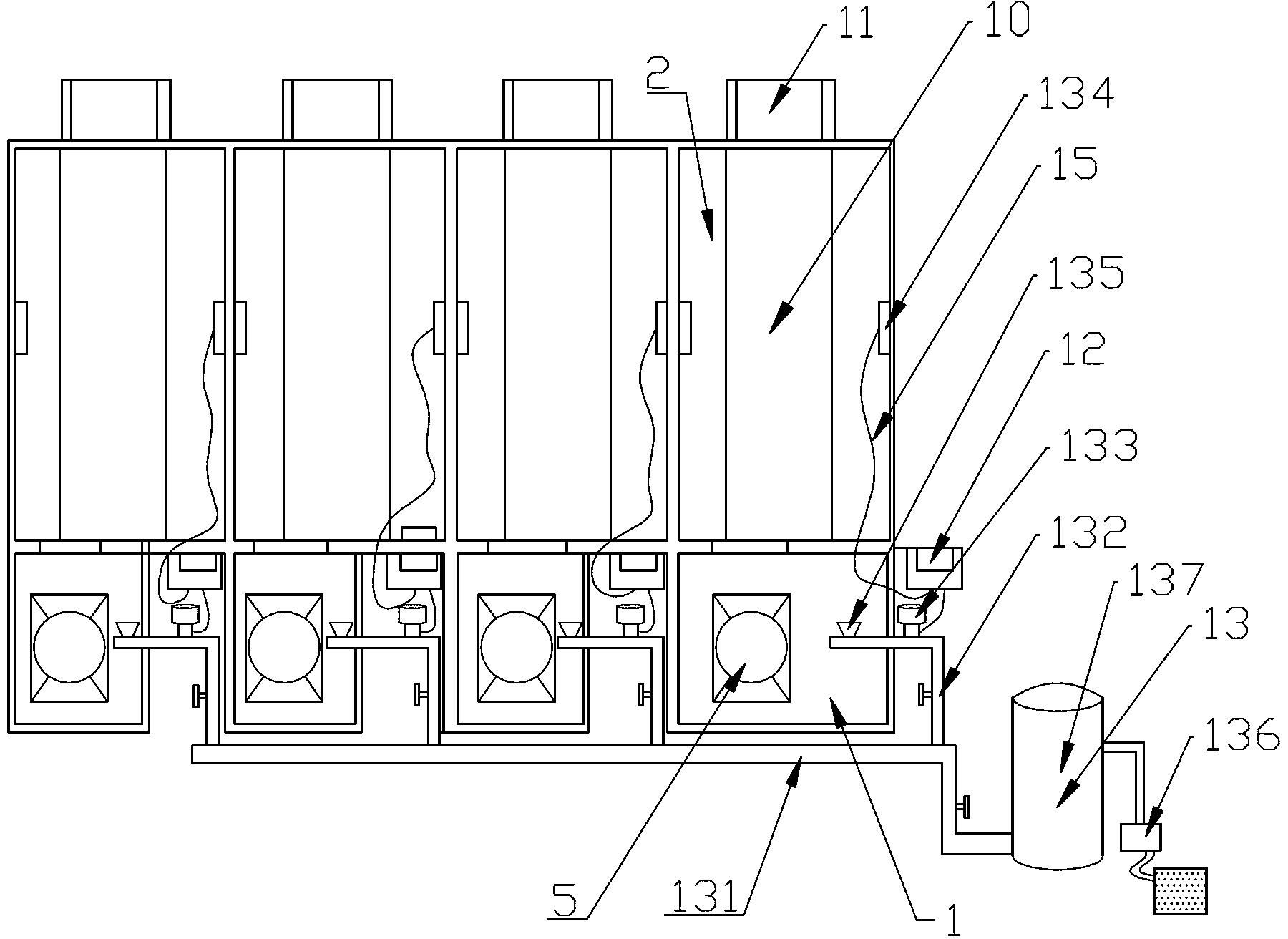

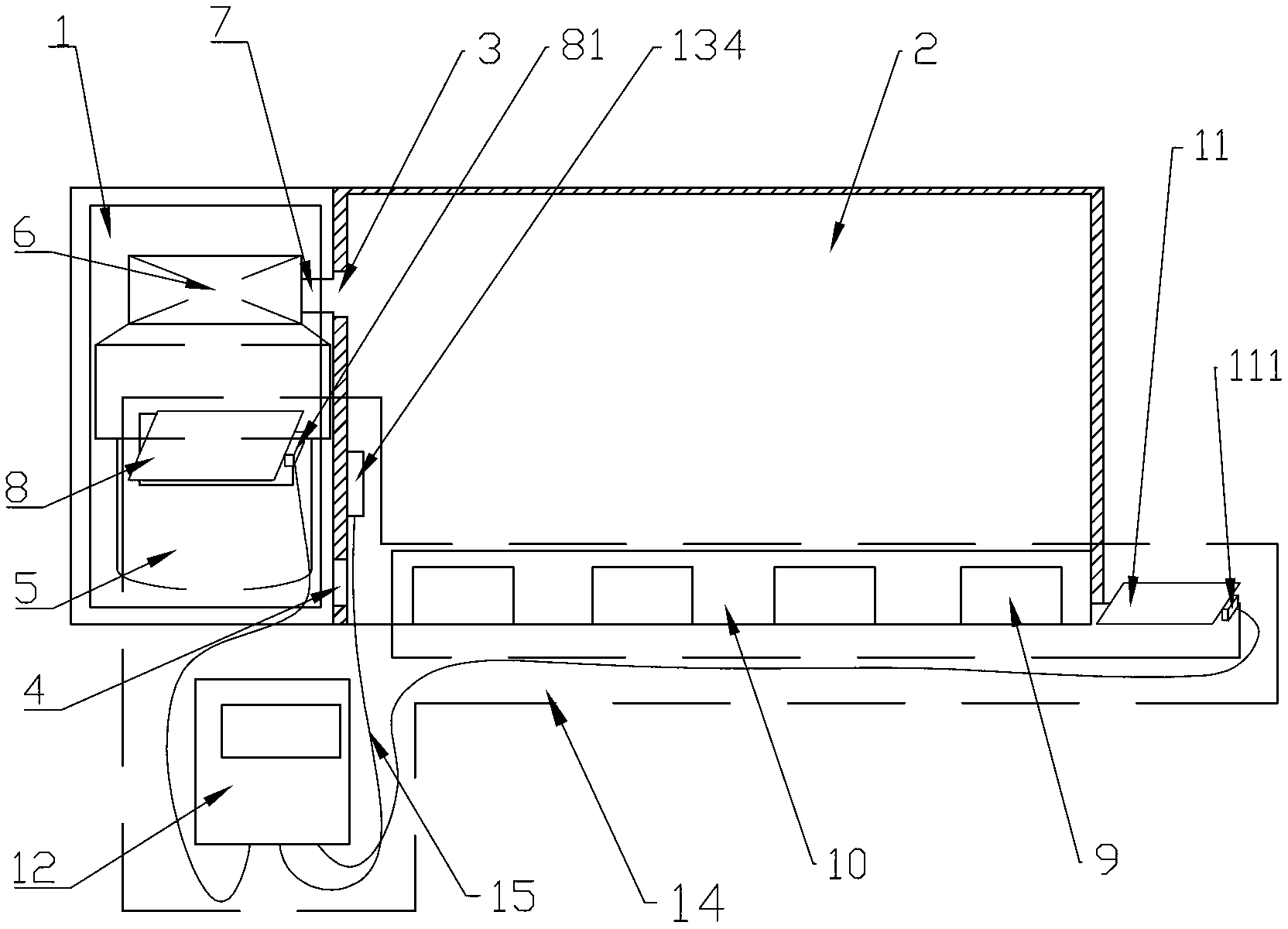

[0020] Such as figure 1 , figure 2 As shown, this kind of dense drying room humidity control system includes a heating room 1 and a baking room 2, and the upper and lower ends of the wall between the heating room 1 and the baking room 2 are respectively provided with an upper ventilation channel 3 and a lower ventilation channel 4. The heating chamber communicates with the baking chamber 2 through the upper and lower ventilation passages. The heating chamber 1 is provided with a heating furnace 5. The upper part of the heating furnace 5 is provided with a fan 6. The fan 6 is connected through the fan exhaust port 7. On the upper air passage 3, a cold air door 8 is provided on the side wall of the heating chamber 1 to control the air flow, and the bottom of the baking chamber 2 is provided with a moisture removal channel 10 with a vent 9. In the baking chamber 2 There is a row of wet windows 11 at the end of the external dehumidification channel 10, which is characterized in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com