Enamel barrel oven and operation method thereof

A baking oven and enamel technology, which is applied in the field of enamel barrel baking equipment, can solve the problems of uneven oven temperature, poor baking effect, and poor working environment, and achieve good baking effect, low cost, and good working environment. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

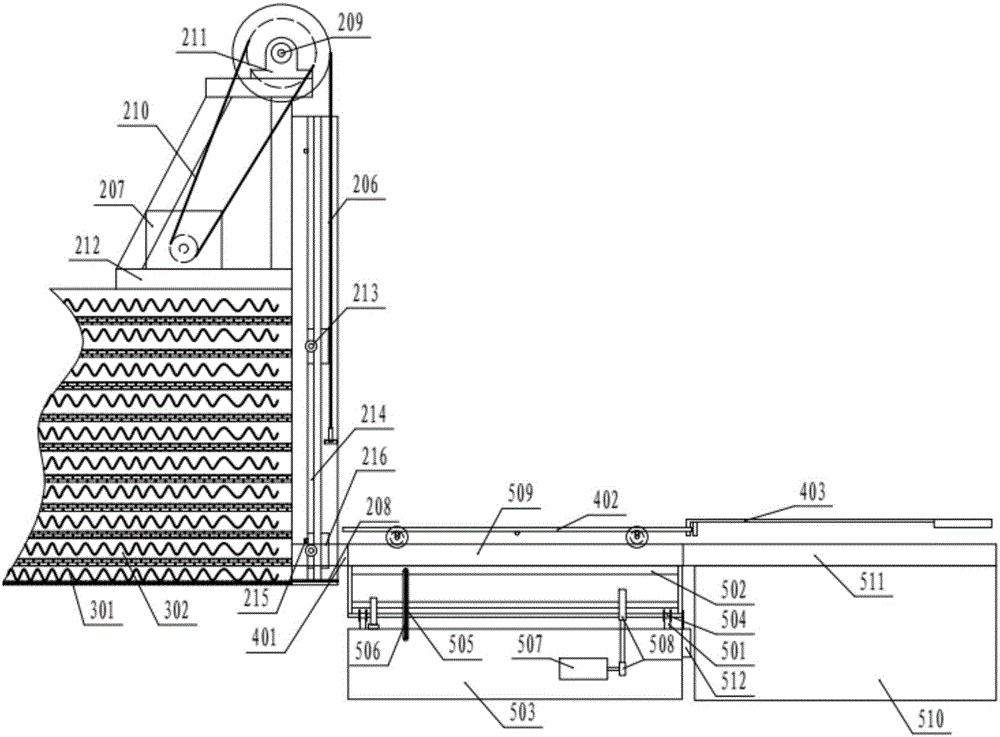

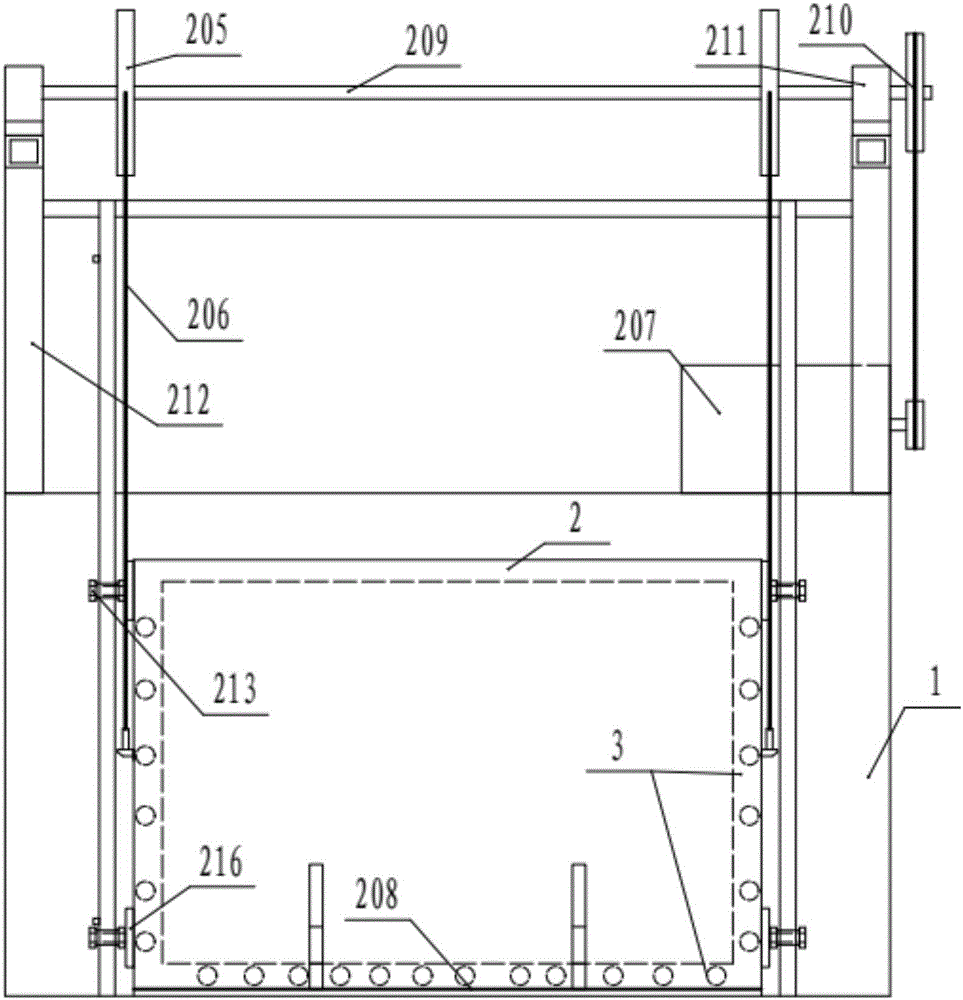

[0028] Embodiment 1: as Figure 1-Figure 4 As shown, an enamel barrel oven includes a bar-shaped box body 1 and a box door 2 arranged at the front end of the box body 1 , and an electric heating device 3 is provided on the inner bottom and sides of the box body 1 .

[0029] Preferably, the above-mentioned box door 2 is connected to the box body 1 through a lifting mechanism, and the lifting mechanism includes two sprockets 205, two chains 206 and a driving motor 207, and the two sprockets 205 are fixedly connected side by side on the same rotating shaft 209, and the wheels The disc girth is greater than the height of the door of the casing 1, the two ends of the rotating shaft 209 are connected to the bearing seat 211 and connected to the drive motor 207 through the sprocket chain mechanism 210, and one end of each chain 206 is vertically fixedly connected to the edge of the sprocket 205, The other end is fixedly connected to the side of the box door 2, the sprocket 205 rotate...

Embodiment 2

[0037] Embodiment 2: a kind of operation method of enamel barrel baking oven, this method comprises the following steps:

[0038] (1) Put the enamel barrel to be baked on the conveying vehicle;

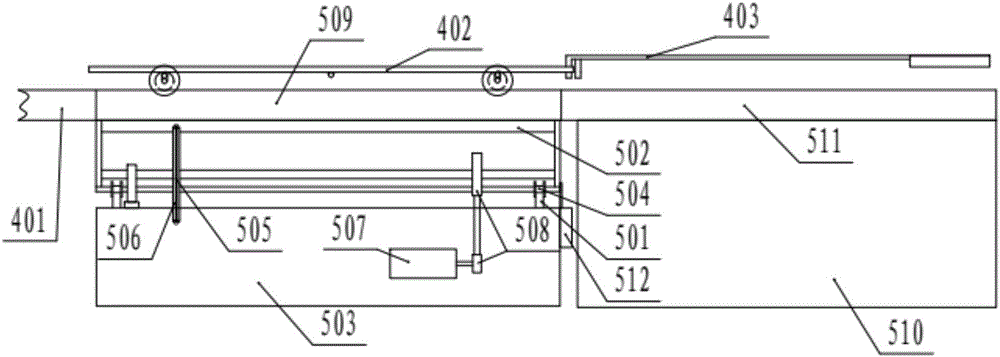

[0039] (2) The operating handle controls the horizontal drive motor to drive the horizontal sliding table to move to the left. When the touch switch 2 is touched, the horizontal drive motor is stopped;

[0040] (3) Start the drive motor of the door through the operating handle to open the door, move the door to a certain position, and stop the drive motor when the touch switch is touched;

[0041] (3) Push the conveyor cart into the oven through the pull hook;

[0042] (4) Control the sliding table to move right to the designated position through the operating handle, put it on the conveyor car, and load it. After baking for a certain period of time, open the box door through the operating handle, and pull the conveyor car out with the hook and place it on the track of the conveyor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com