Energy-saving tundish submersed nozzle baking oven and baking method

A baking method and a technology of a baking oven, which are applied in the direction of manufacturing tools, casting molten material containers, and configuration of indicating equipment/measuring equipment, etc., which can solve the problems of uneven baking temperature of nozzles, reduction of baking gas consumption, and baking Large gas consumption and other problems, to achieve the effect of simple and practical baking, low gas consumption, and avoid heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

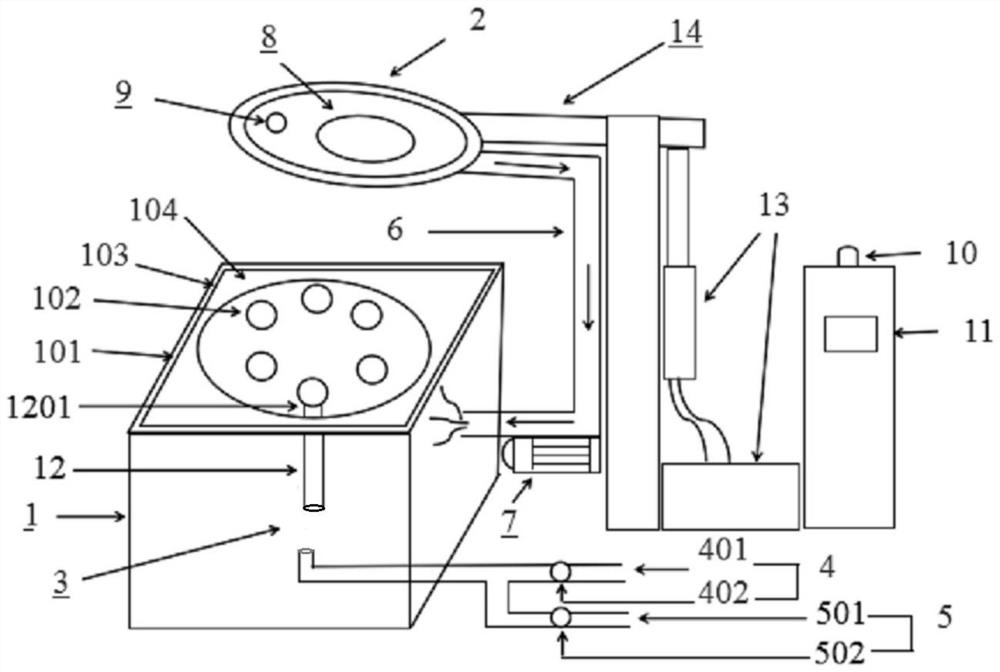

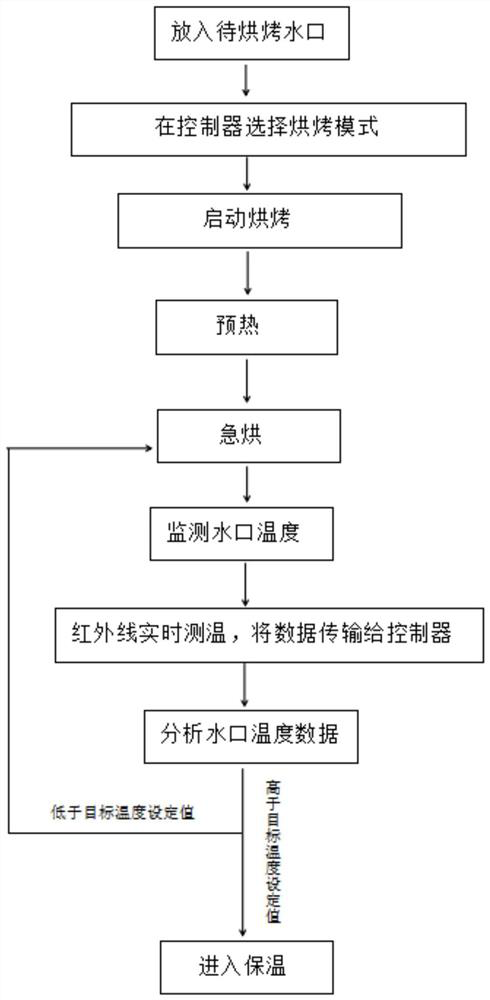

[0139] An energy-saving medium-package immersion nozzle oven, such as figure 1 shown, it is baked as follows:

[0140] ①It is necessary to pass the submerged nozzle 12 of the middle bag to be baked through the nozzle placement hole 102 on the box cover 101, respectively put the nozzle 12 into the box 1, and keep the nozzle 12 vertical. At this time, the nozzle bowl 1201 will be stuck in The nozzle is placed above the hole 102 . The number of nozzle placement holes 102 is 6, and the number of nozzle placement holes 12 is also 6; the shortest distance between two adjacent nozzle placement holes 102 is 140mm, and the shortest distance between the nozzle placement holes 102 and the burner is 120mm, the hole diameter of the nozzle placement hole is 115mm. The inner cavity size of the box body 1 is 1200mm×1200mm×1200mm.

[0141] ②Confirm the ignition status, if there is no fire, press the ignition switch button on the control device 11 to confirm that the burner 3 is on fire.

...

Embodiment 2

[0149] According to Example 1, the difference is that the shortest distance between two adjacent nozzle placement holes 102 is 170 mm.

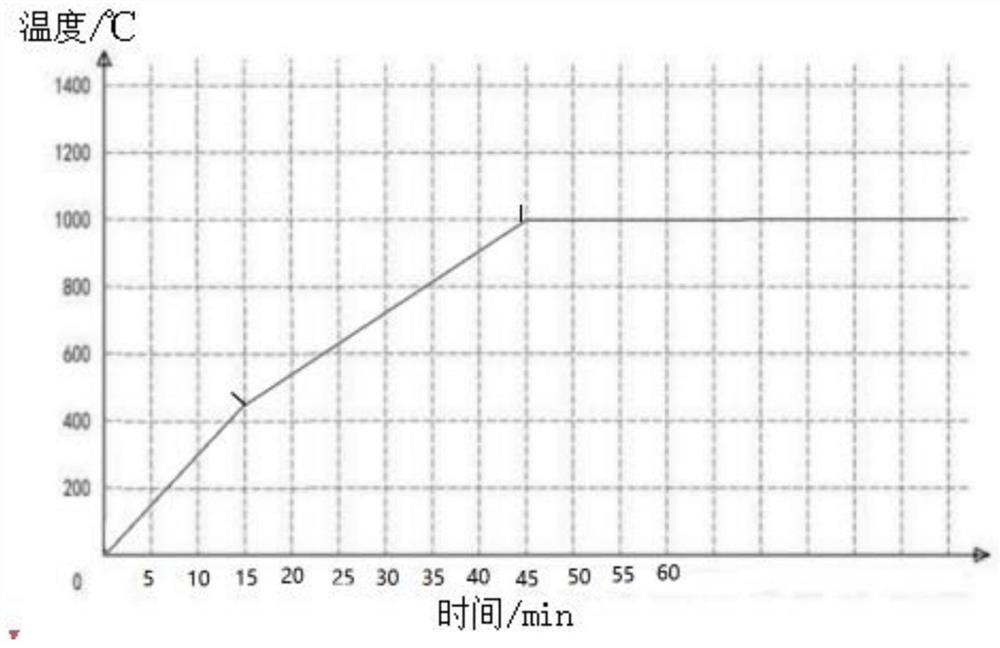

[0150] The preheating time of this embodiment is 20min, and the rapid baking time is 38min.

Embodiment 3

[0152] According to Example 1, the difference is that the size of the inner cavity of the box body 1 is 1600mm×1600mm×1600mm.

[0153] The preheating time of this embodiment is 26min, and the rapid baking time is 46min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com