Crawler type oven with heat insulation cover

A heat shield and crawler-type technology, applied in food ovens, baking, food science, etc., can solve the problems of slow heat transfer, waste of time and energy, unfavorable preservation of oven heat, etc., to achieve convenient cleaning and tidying, The effect of reducing temperature drop and flexible and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

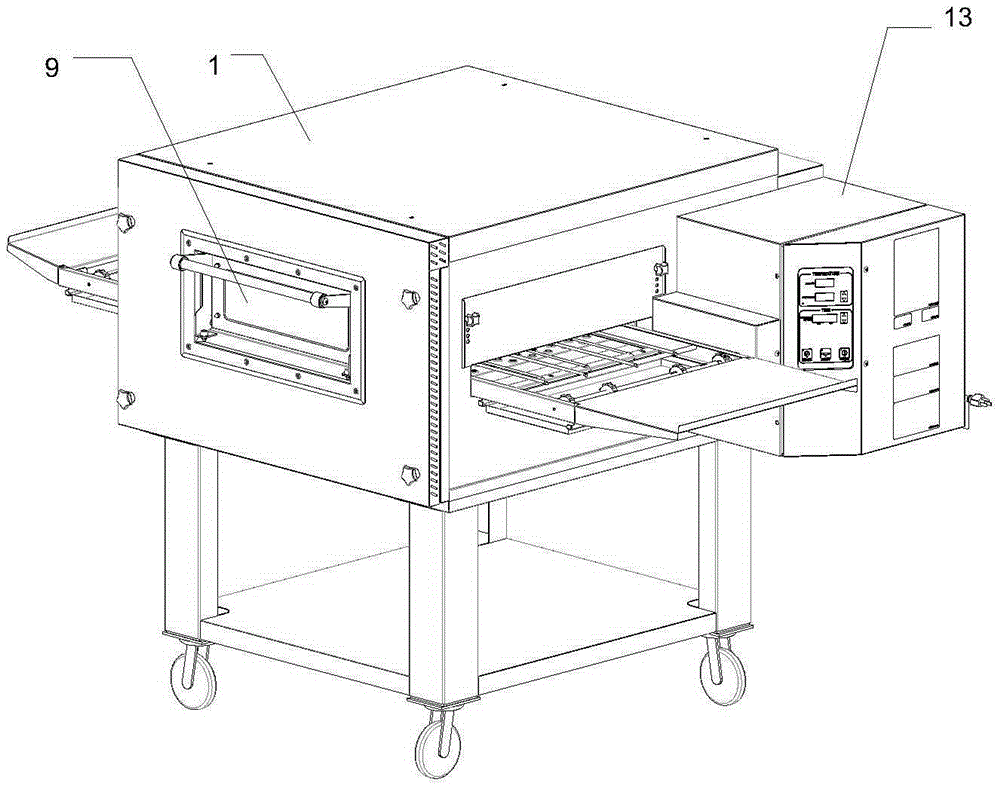

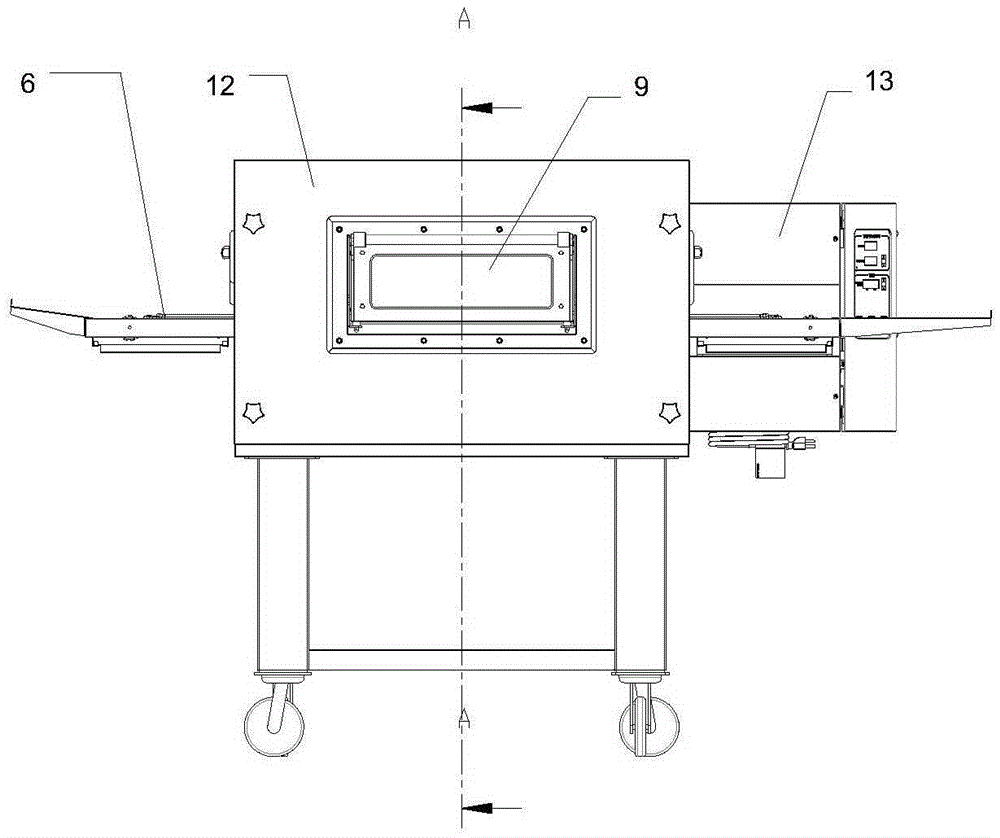

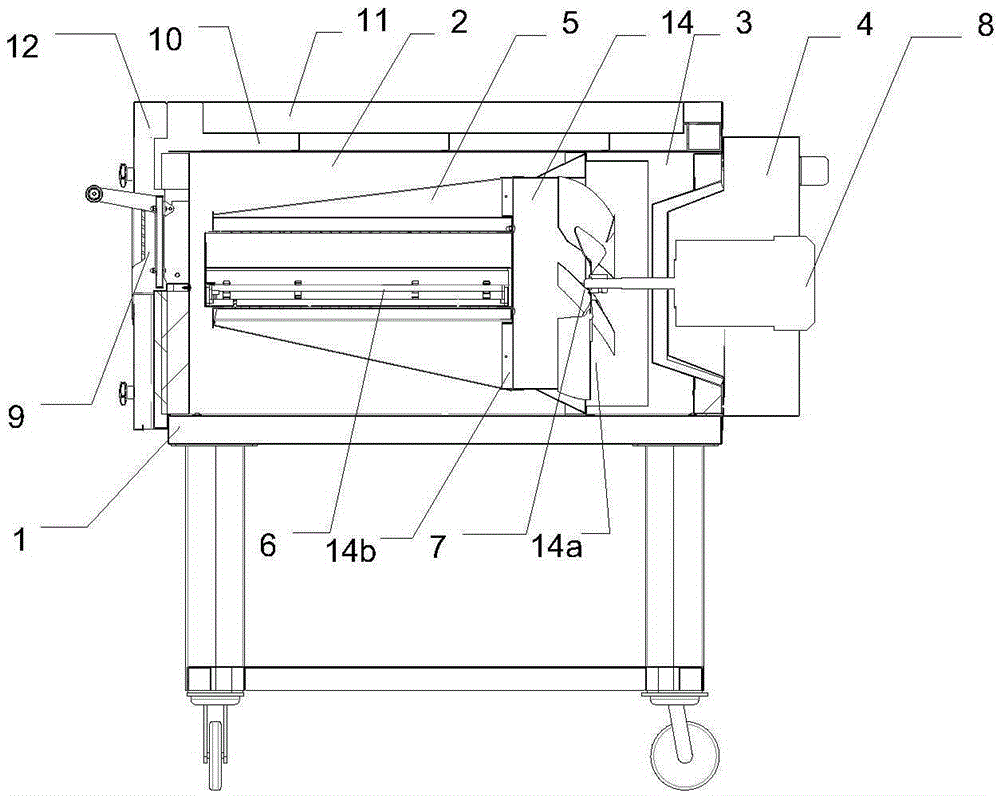

[0030] figure 1 It is a perspective view of the present invention. figure 2 is a side view of the present invention. image 3 yes figure 2 Sectional view along line A-A. combine figure 1 , figure 2 and image 3 visible:

[0031] The present invention includes a furnace body 1 installed on a frame, and the furnace body 1 has a furnace chamber 2 and a heat source chamber 3 located at the rear side of the furnace chamber 2 . It also includes an air storage box 14, the air storage box 14 is located between the furnace chamber 2 and the heat source chamber 3, and an air storage box opening 14a is provided on the side facing the heat source chamber 3, and an air storage box is provided on the side close to the furnace chamber 2 box air outlet 14b. A fan 7 disposed toward the opening 14a of the air storage box is installed in the heat source chamber 3 .

[0032] A plurality of wind guide boxes 5 arranged up and down are installed in the furnace cavity 2, and the air inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com