Tunnel kiln with angle-adjustable circulating air

A circulating air and tunnel furnace technology, which is applied in the field of tunnel furnaces, can solve the problems of uneven air outlet, non-adjustable angle, and inability to select convection intensity, etc., and achieve the effects of reasonable layout, enhanced versatility, and excellent baking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

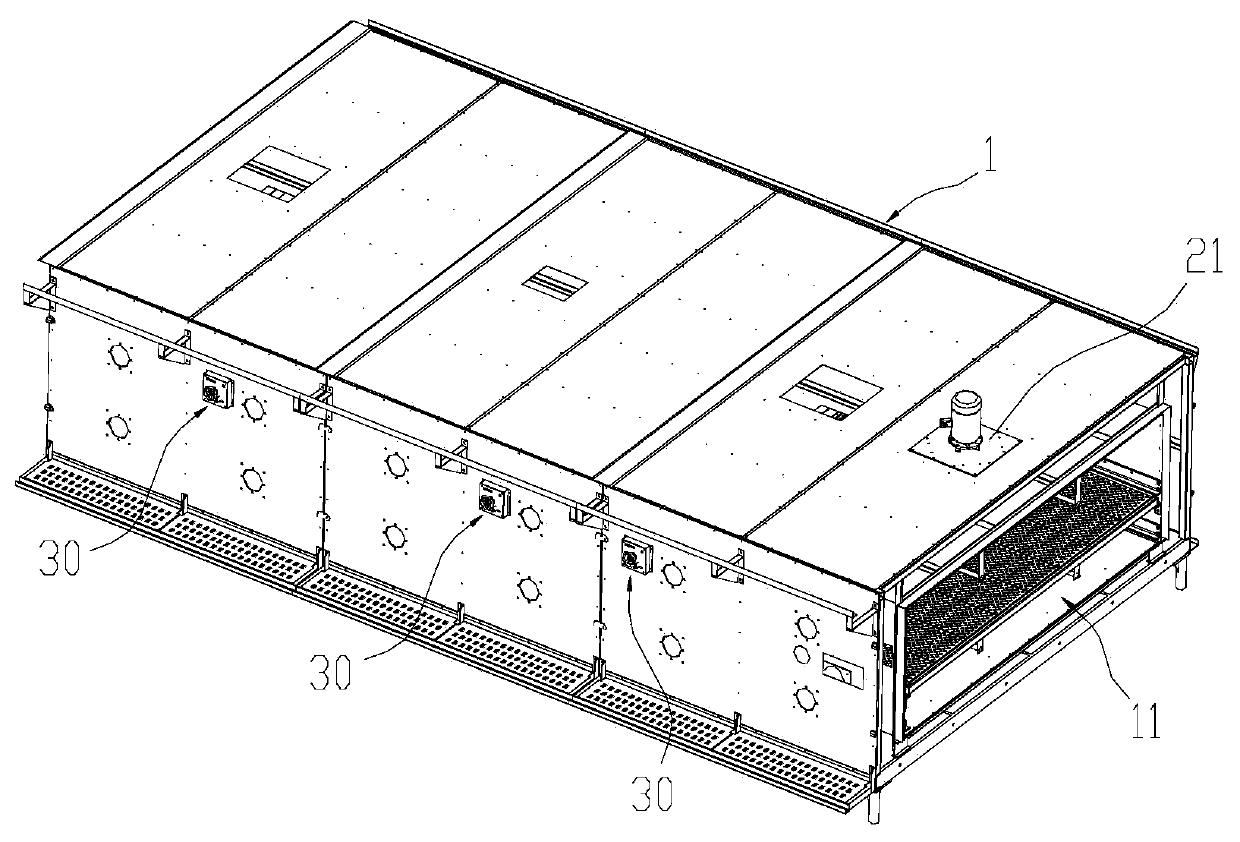

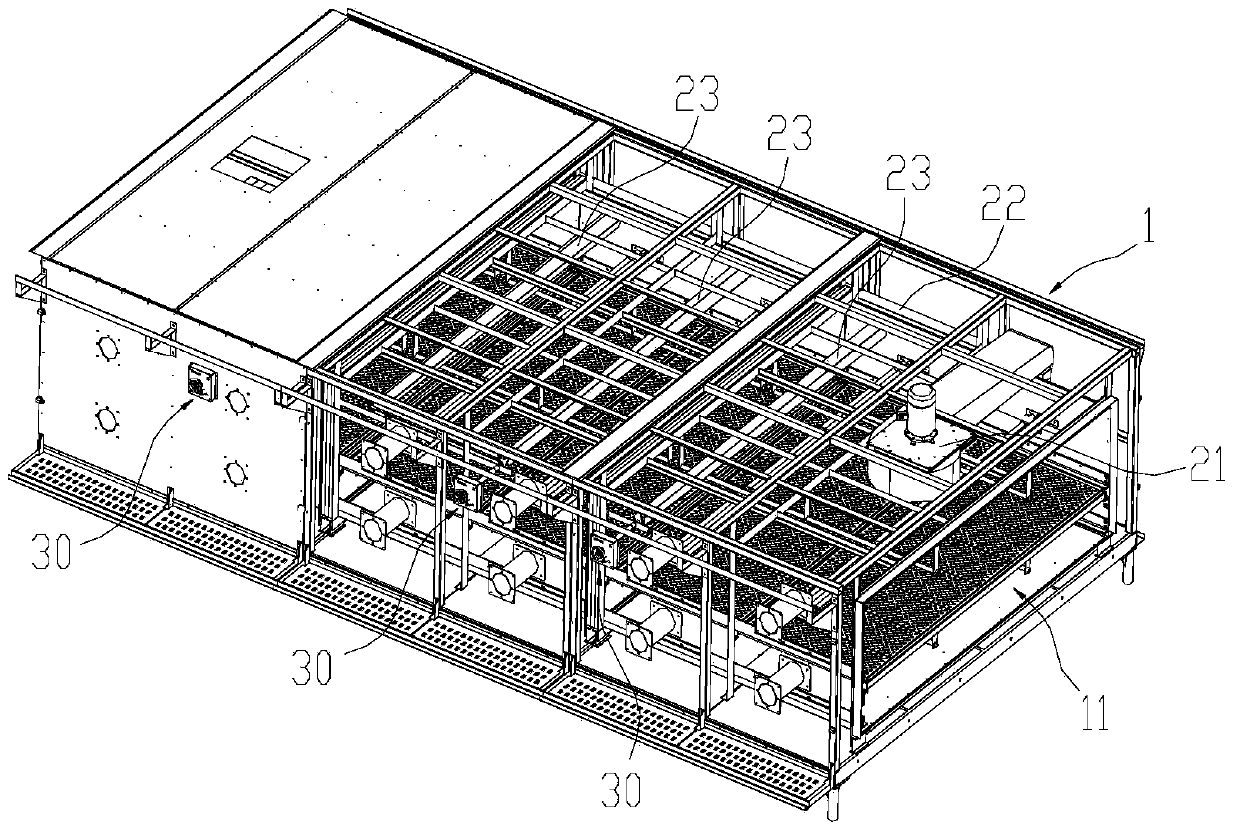

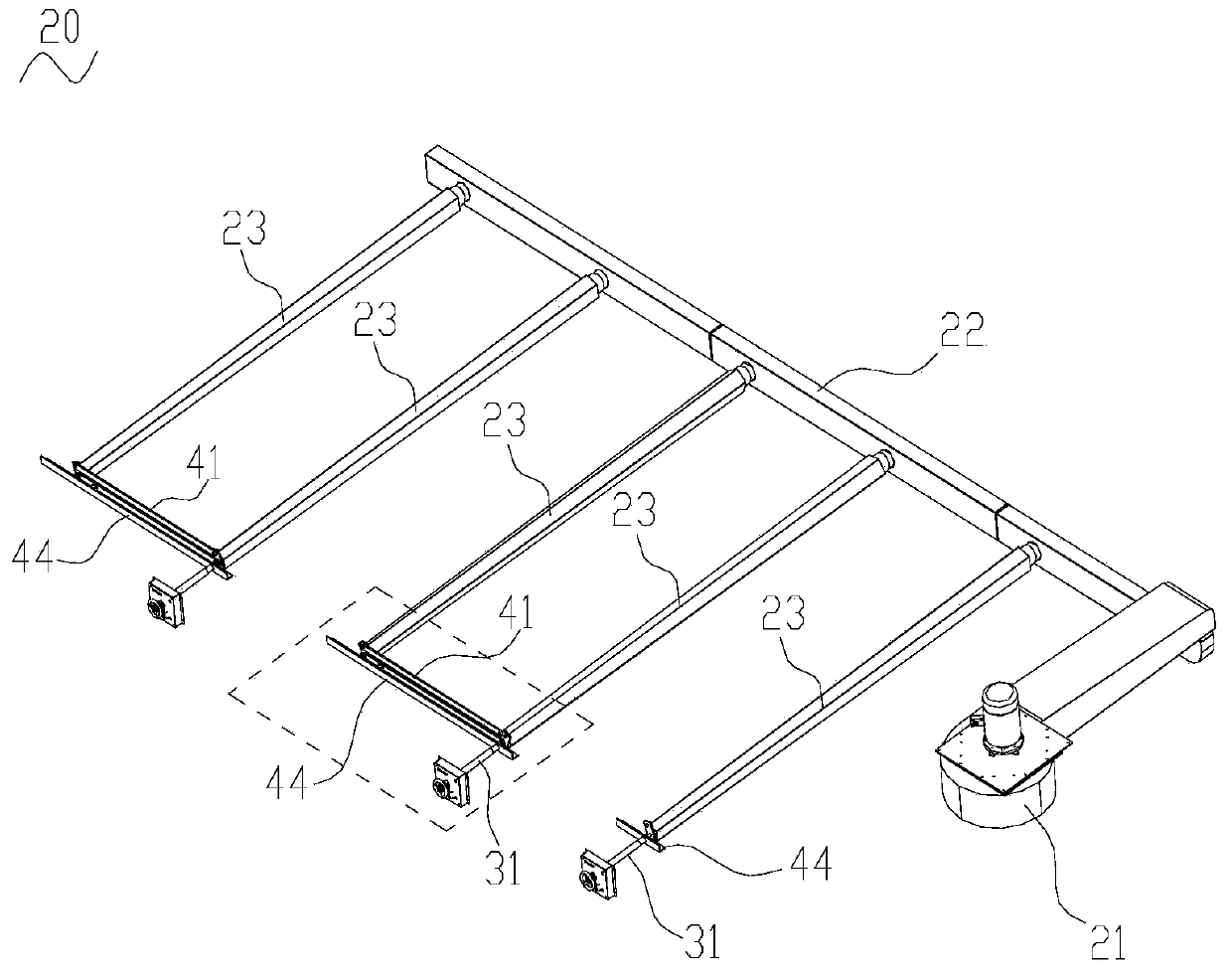

[0023] see Figure 1 to Figure 4 , the present invention discloses a tunnel furnace with adjustable angle circulating air, including a heating system, a cabinet 1 with a baking channel 11 and a circulating air system 20 installed above the baking channel 11, the heating system It is used to heat the air in the furnace; the cabinet 1 is rectangular, and the cabinet 1 is a box body provided with a material inlet and a material outlet, and the inner space of the box body forms the baking channel 11; the circulating air system 20 includes a centrifugal fan 21 fixedly mounted on the chassis 1, a main air duct 22 communicated with the centrifugal fan 21 and several return air ducts 23 arranged at intervals on the main air duct 22, and the main air duct 22 is along the The length direction of the baking passage 11 is fixed on the cabinet 1, and the several ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com