Incombustible oil depot under bombing of enemy plane

A technology for oil depots and enemy aircraft, which can be used in fire rescue and other directions to solve problems such as inability to extinguish fires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

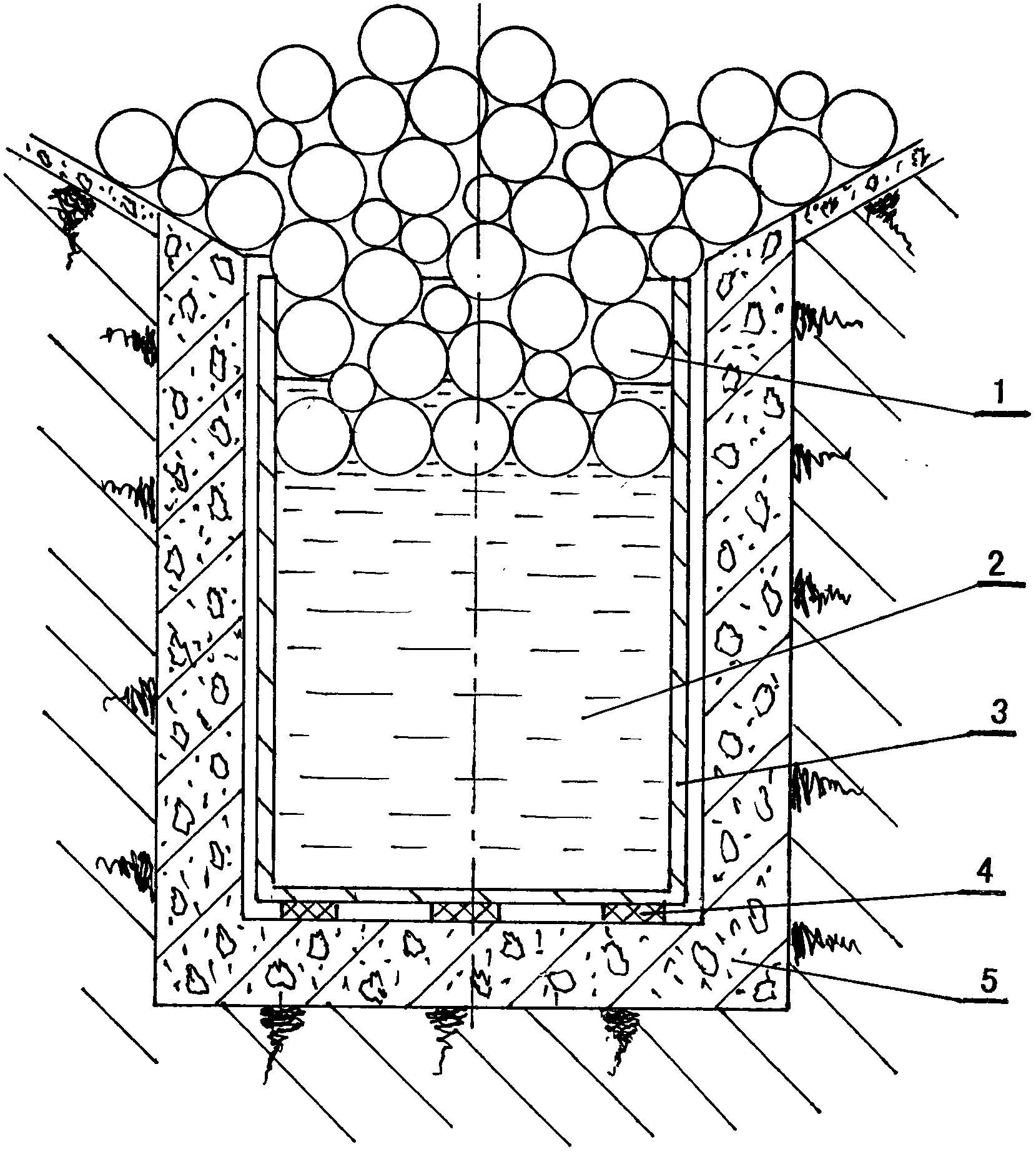

[0012] Below the embodiment schematic diagram of accompanying drawing of the present invention is described in further detail:

[0013] Such as figure 1 Shown a kind of enemy plane bombing can not burn fuel depot and is made up of thin-shell hollow steel ball 1, fuel oil 2, fuel tank 3, fuel tank pad 4, fuel tank seat 5.

[0014] The above-mentioned fuel tank 3 is placed in the fuel tank seat 5, the bottom surface of the fuel tank 3 is padded with a fuel tank spacer 4, the fuel oil 2 is filled in the fuel tank 3, and the thin-shell hollow steel balls 1 are stacked on the fuel oil 2, the fuel tank 3, and the fuel tank seat 5 The material of the fuel tank 3 is preferably steel, and the fuel tank oil outlet pipe of the fuel tank 3 and the suction pipe at the bottom of the fuel tank can be down according to the inner wall of the fuel tank 3 .

[0015] The thin-shell hollow steel ball 1 mentioned above has at least two kinds of thin-shell hollow steel balls 1 with different sizes....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com