Dry powder extinguisher

A dry powder fire extinguishing and ignition device technology, which is applied in fire rescue and other fields, can solve the problems of easy explosion and safety hazards, and achieve the effect of increasing pressure and avoiding safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

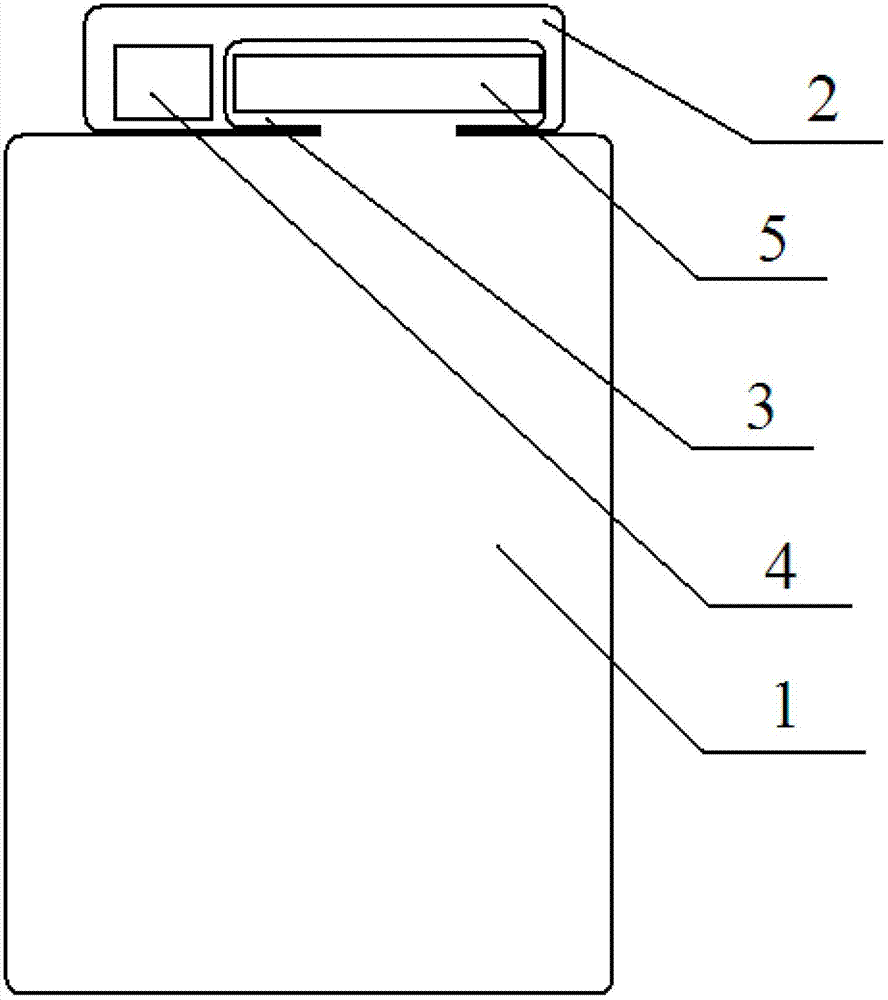

[0037] figure 1 It is a cross-sectional view of the dry powder fire extinguishing device provided by Embodiment 1 of the present invention, see figure 1 As shown, the dry powder fire extinguishing device provided by the present invention includes: a tank body 1 and a fixing seat 2 sealingly connected with the tank body 1; the fixing seat 2 is also provided with a combustion chamber 3 communicating with the inside of the tank body 1 The combustion chamber 3 is also connected with an ignition device 4; the combustion chamber 3 is provided with a combustion charge 5.

[0038] In this embodiment one, since the fixed seat 2 is provided on the tank body, the combustion chamber 3 communicated with the interior of the tank body 1 is provided on the fixed seat 2, so when the ignition device 4 is ignited, and the combustion chamber 3 is placed When the burning powder 5 is ignited, the burning powder 4 burns to produce a large amount of gas rapidly, and the combustion chamber 3 communic...

Embodiment 2

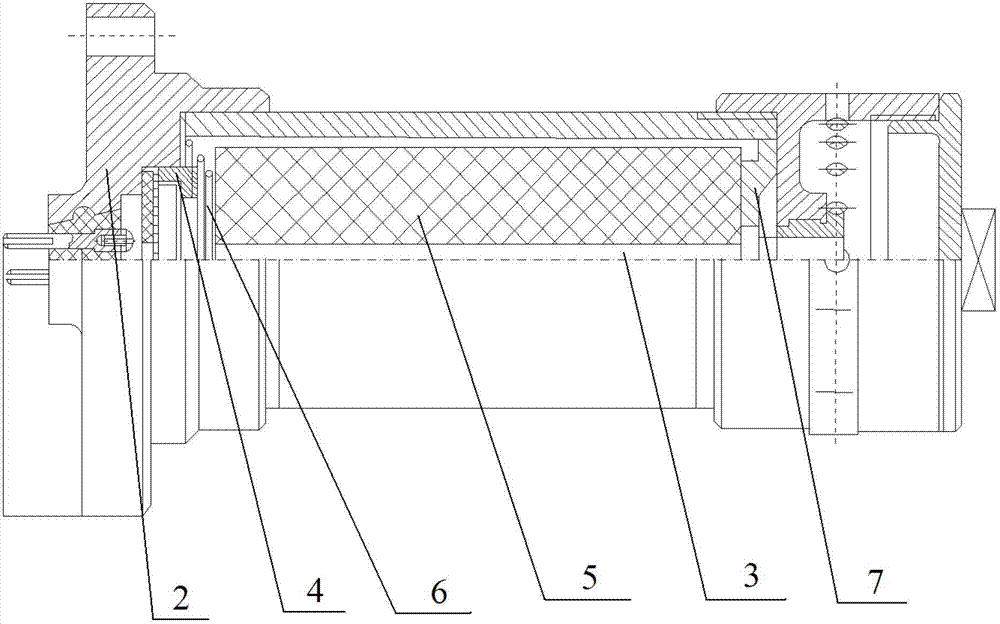

[0040] figure 2 It is a schematic structural view of the combustion chamber 3 in the dry powder fire extinguishing device provided by Embodiment 2 of the present invention, see figure 2 As shown, on the basis of the first embodiment above, the combustion chamber 3 is also provided with a solid medicine spring 6 and a medicine retaining plate 7 for fixing the combustion grain 5; The medicine plates 7 are respectively arranged at both ends of the combustion chamber 3; the burning medicine column 5 is arranged between the solid medicine spring 6 and the medicine blocking plate 7 and abuts against both.

[0041] In the second embodiment, the two ends of the combustion chamber 3 are respectively provided with a solid medicine spring 6 and a medicine retaining plate 7, and the solid medicine spring is elastic, so that the combustion powder column 5 can be fixed on the solid medicine spring 6 and the medicine retaining plate 7, it is ensured that no matter in the process of transp...

Embodiment 3

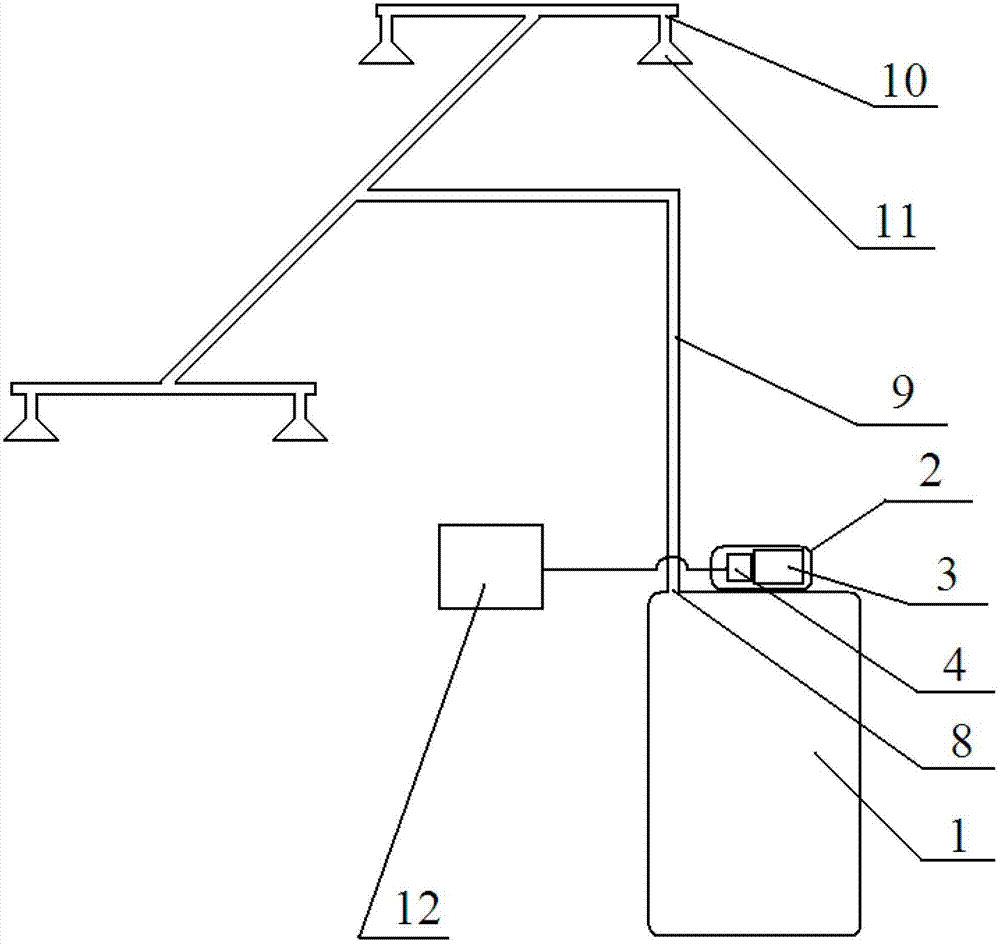

[0043] see image 3 As shown, the dry powder fire extinguishing device provided by the present invention is based on the above two embodiments, and the tank body 1 is also provided with a dry powder outlet 8 .

[0044] In the third embodiment, the ignition device 5 ignites the combustion powder column 5, and after a large amount of gas is generated, the air pressure in the tank body 1 is higher than the atmospheric pressure, so the dry powder stored in the tank body 1 is discharged from the dry powder outlet 8 Squeeze it out. The dry powder is extruded and ejected from the dry powder outlet 8, so as to reach the fire site and achieve the purpose of extinguishing the fire.

[0045]In the present invention, the dry powder fire extinguishing device can be set to be movable, or the dry powder fire extinguishing device can be set to be fixed. When the dry powder fire extinguishing device was fixed, the powder delivery pipeline 9 was also connected to the dry powder outlet 8 . Du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com