Electrostatic fabric filter for controlling fine particles PM2.5 and mercury collaborative removal

An electric bag compounding and fine particle technology, which is used in combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as the need to improve the removal efficiency of fine particles, reduce the service life of filter bags, increase maintenance costs and management difficulties, etc. , to achieve uniform distribution of sorbent and good effect of mercury removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following embodiments will further illustrate the present invention in conjunction with the drawings.

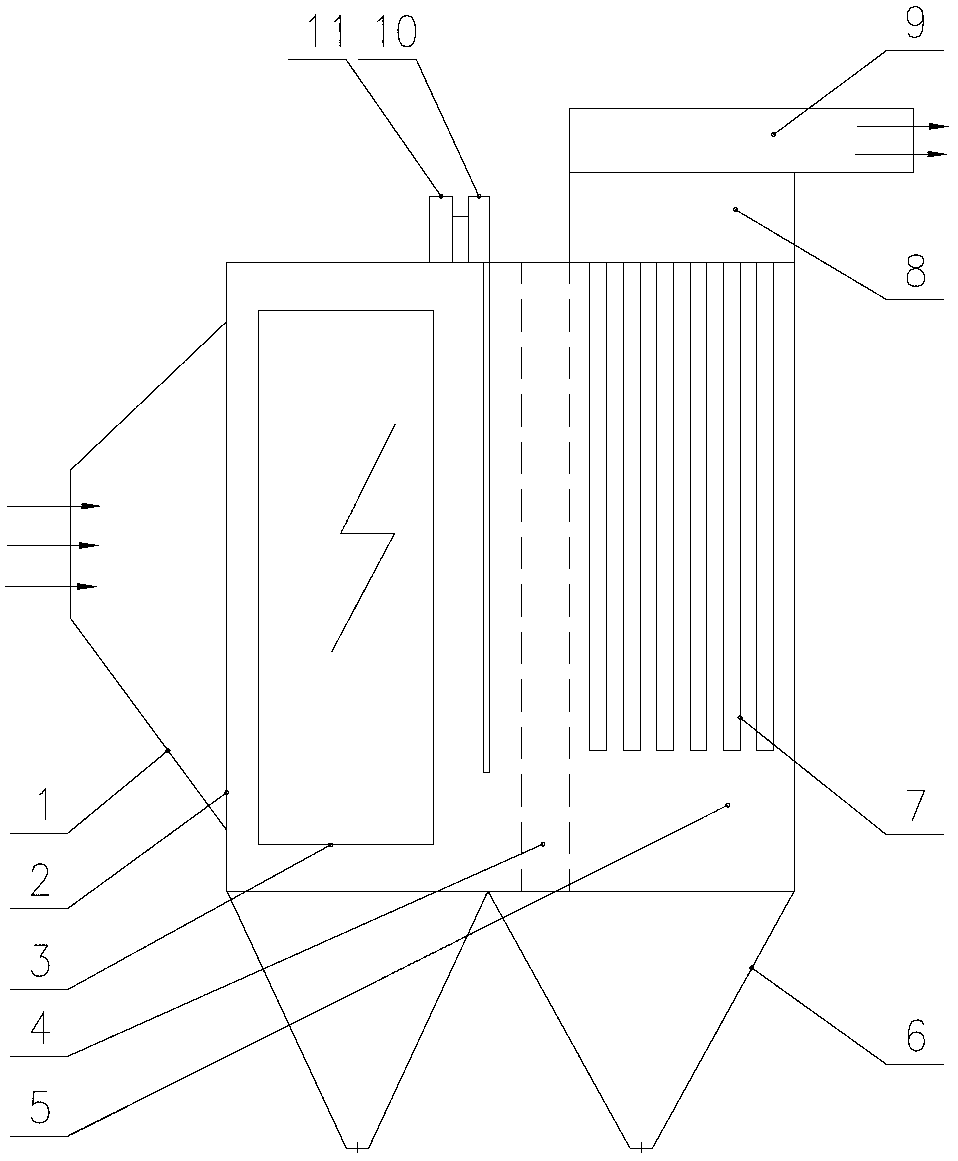

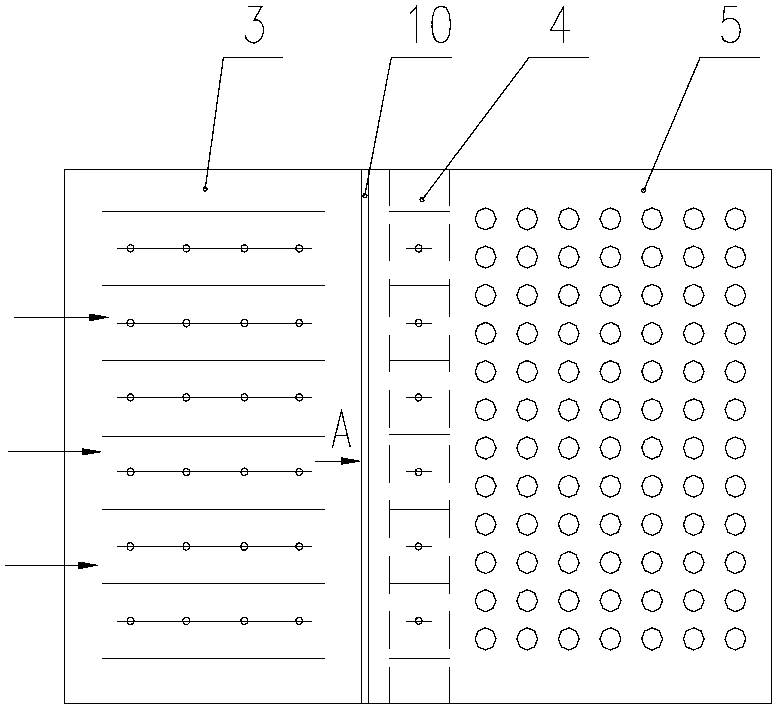

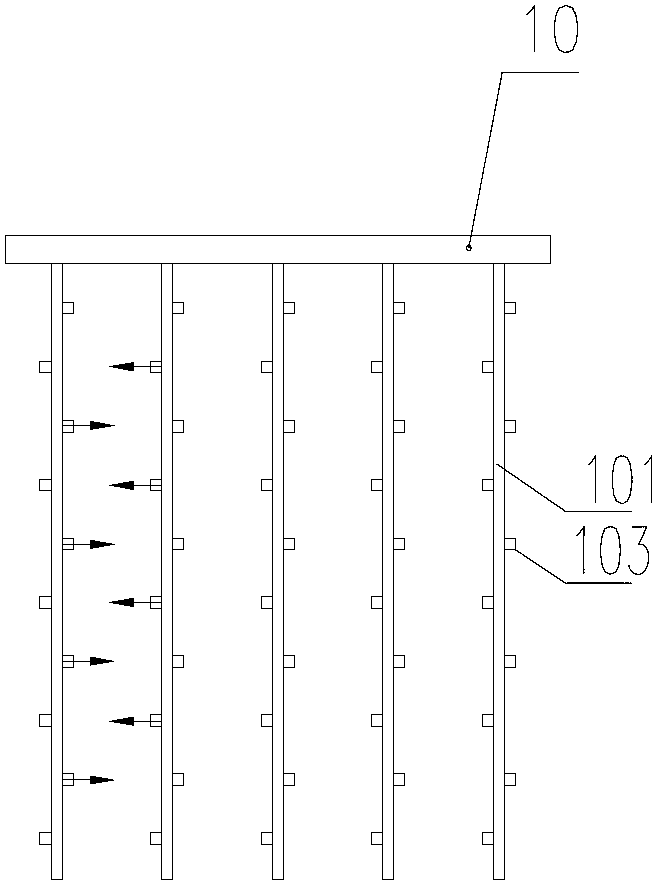

[0020] See Figure 1~4 The embodiment of the present invention is provided with an electric bag composite dust collector, an adsorbent injection device 10 and an adsorbent container 11; the electric bag composite dust collector is provided with an imported horn 1, a shell 2, an electric field area 3, and an electric bag transition area 4. Bag dust removal zone 5, ash hopper 6, clean air chamber 8 and outlet flue 9; the inlet horn 1 is set at the inlet of the shell 2, the electric field zone 3, the electric bag transition zone 4 and the bag dust removal zone 5 Set in the shell 2, the electric field zone 3 is set behind the imported horn 1, the electric bag transition zone 4 is set between the electric field zone 3 and the bag dust removal zone 5; the ash hopper 6 is set at the bottom of the shell 2, bag type The dust removal area 5 is provided with a filter bag 7, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com