Rotary spray head device for high-pressure cleaning machine

A technology of high-pressure cleaning machine and rotating nozzle, applied in the direction of spraying device, spraying device with movable outlet, cleaning method and utensils, etc., can solve the problems of poor cleaning efficiency, large water outlet, weak water column force, etc., and prolong the service life. , Improve cleaning efficiency and prevent wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

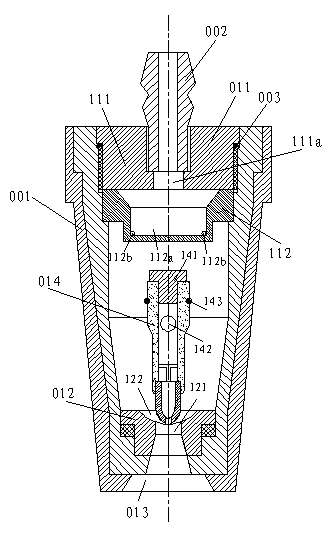

[0014] A rotary nozzle device for a high-pressure cleaning machine, comprising a nozzle cover 001 connected to a water gun, the cover 001 is a conical shell, the upper end of the inner cavity of the cover 001 is provided with a water inlet base 011, and the bottom end is provided with a water outlet base 012, the bottom of the cover body 001 below the water outlet base 012 is provided with a radial through hole 013, and a rotating body 014 is arranged in the cavity between the water inlet base 011 and the water outlet base 012, and the water inlet base 011 is formed by a plug 111 and the water inlet chamber 112, the center of the plug 111 is provided with a water inlet hole 111a, the upper end of the water inlet hole 111a is provided with a screw thread to connect with the water gun joint 002 on it, and the plug 111 is connected to the inner wall of the cover body 001 A sealing ring 003 is arranged at the place, the water inlet cabin 112 is in the shape of a boss, and a stepped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com