Device for cleaning megasonic transducer

A technology of transducers and megasonic waves, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of slow cleaning speed, poor cleaning quality, and low efficiency, and achieve high cleaning efficiency , good cleaning effect, uniform and comprehensive cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

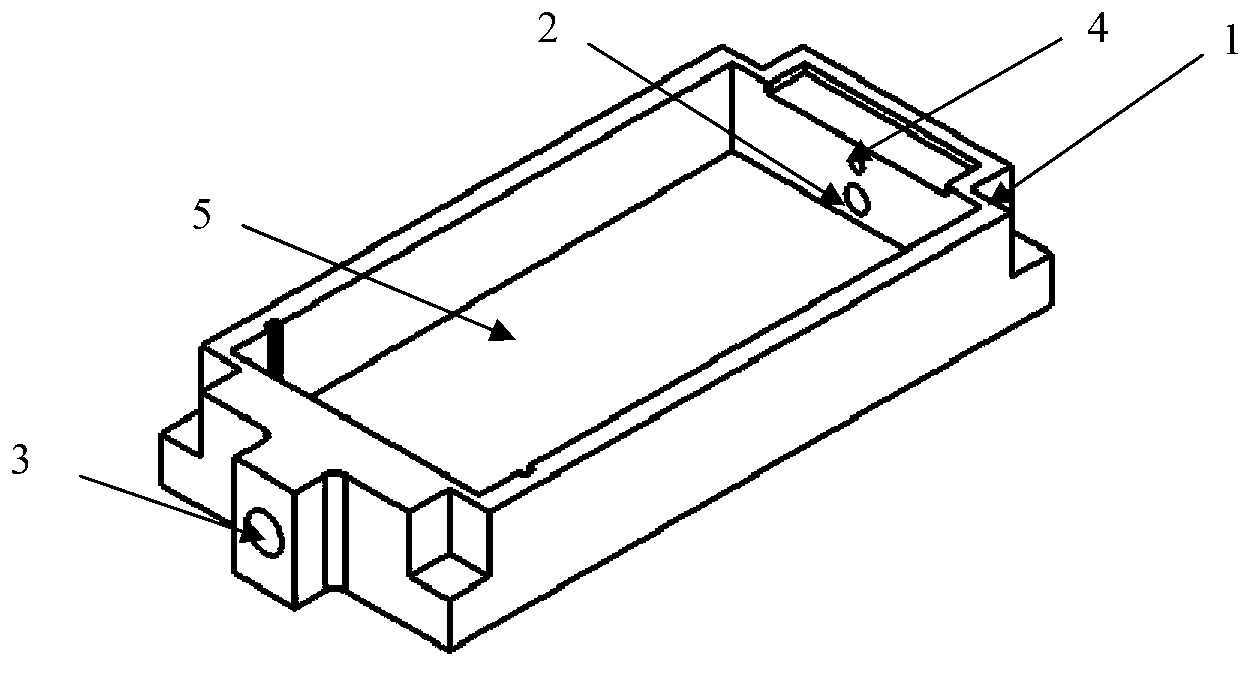

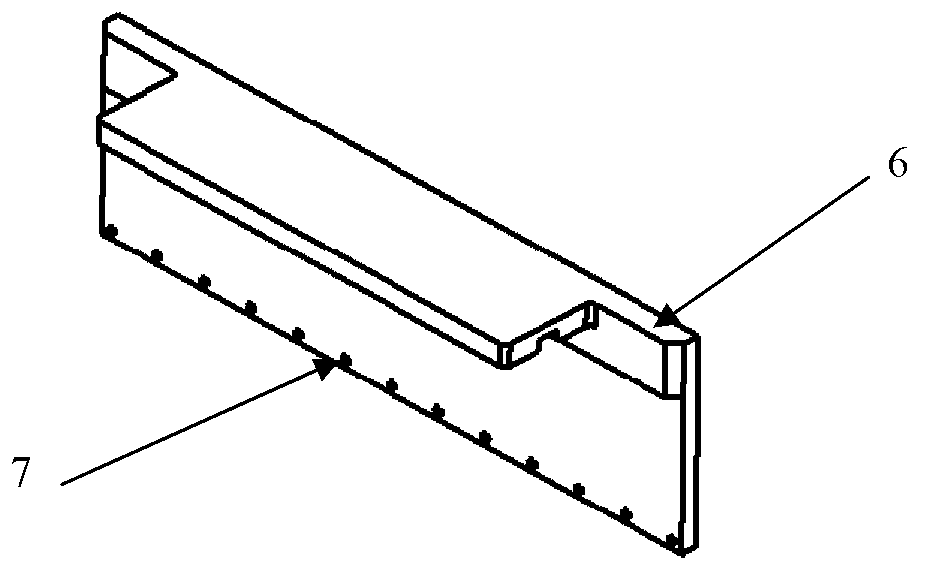

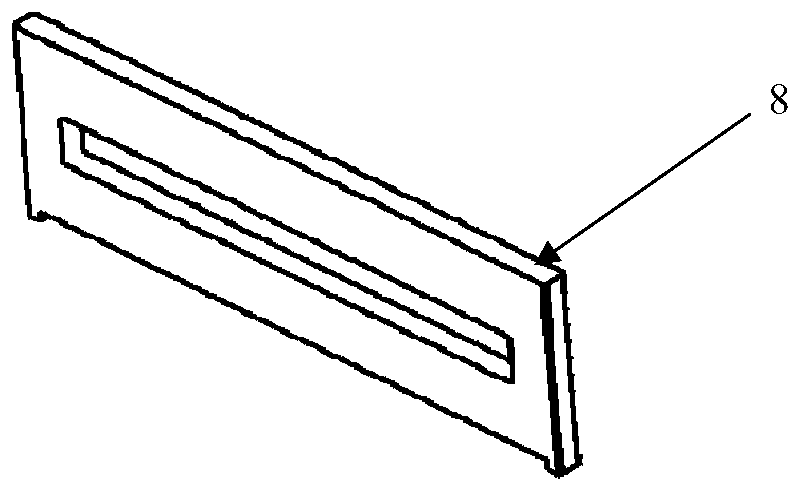

[0024] In the embodiment of the present invention, a trough-type device is used to clean the megasonic transducer. The cleaning device includes a cleaning tank, a baffle and a flow partition, and the baffle and the flow partition are respectively arranged on the liquid inlet side and the liquid outlet of the cleaning tank. side. The cleaning liquid is rapidly flowed through the megasonic transducer to be cleaned, where the cleaning liquid may be pure water.

[0025] The cleaning tank is a quadrilateral tank structure, and a liquid inlet and a liquid outlet are provided on one side and the opposite side of the cleaning tank, and the liquid outlet is larger than the liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com