Wire bending self-made tool for steel stranded wire pulling handle

A technology of steel strands and pull wires, which is applied in the field of making tools for pull wire handles. It can solve the problems of different lengths, high physical exertion, and inconsistent bending angles, etc., and achieve the effect of high-efficiency production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following will be described in conjunction with the accompanying drawings and specific embodiments.

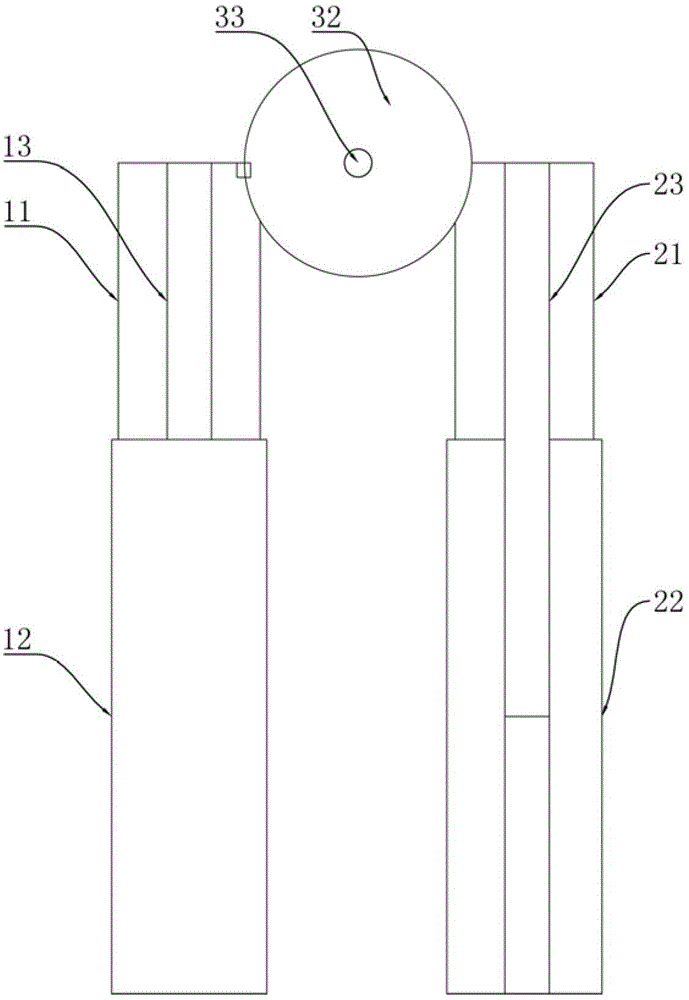

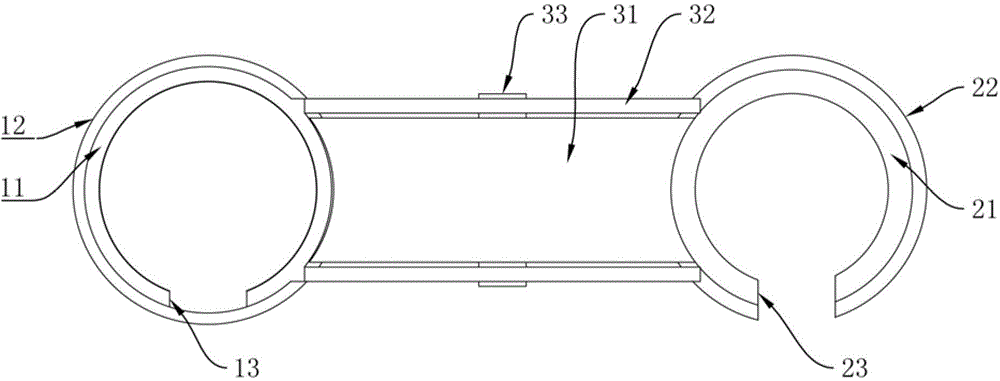

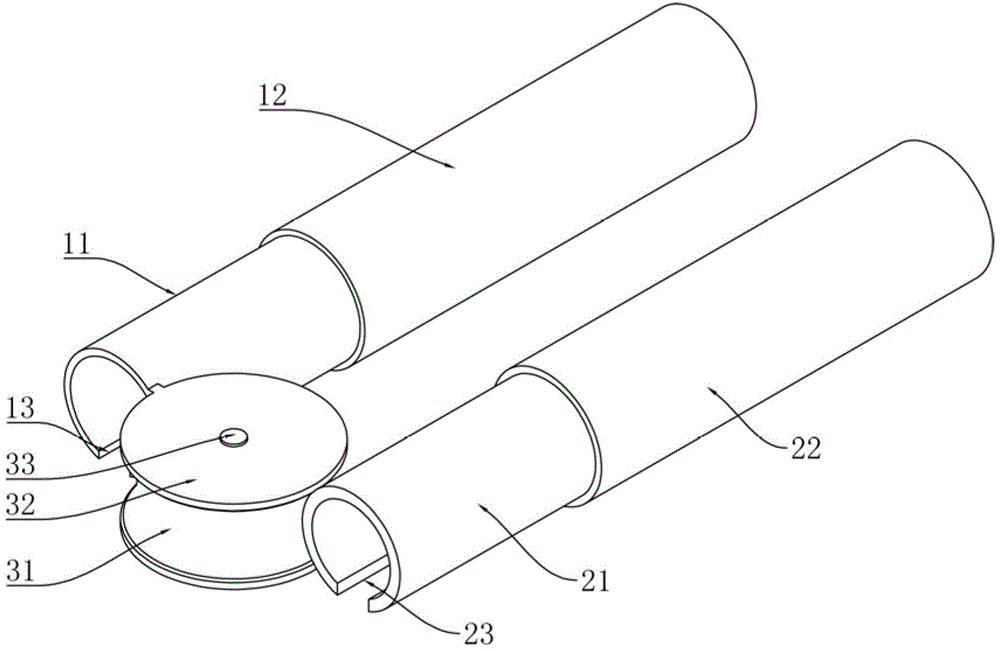

[0013] see Figure 1 to Figure 3 . The self-made tool for bending the head of the steel strand guy wire includes a left handle pipe 11 and a right handle pipe 21, and the axis lines of the two handle pipes are always on the same plane. The left handle tube 11 is provided with a first slit 13 , and the left handle tube 11 is covered with a left hand overtube 12 . The width of the seam is slightly larger than the diameter of the backguy, which is convenient for putting the backguy in or taking it out. The right handle tube 21 is provided with a second slit 23 , and the right handle tube 21 is covered with a right-hand outer tube 22 , and the right-hand outer tube 22 is provided with a third slit. The width of the seam is slightly larger than the diameter of the backguy, which is convenient for putting the backguy in or taking it out. Slits of the right handle pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com