Method used for high-temperature liquid core mold dismantling of large-scale extra-thick plate blank

A technology of extra-thick slabs and high-temperature belts, applied in the field of high-temperature belt liquid core boxing, can solve the problems of macro-segregation, cracks, shrinkage porosity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

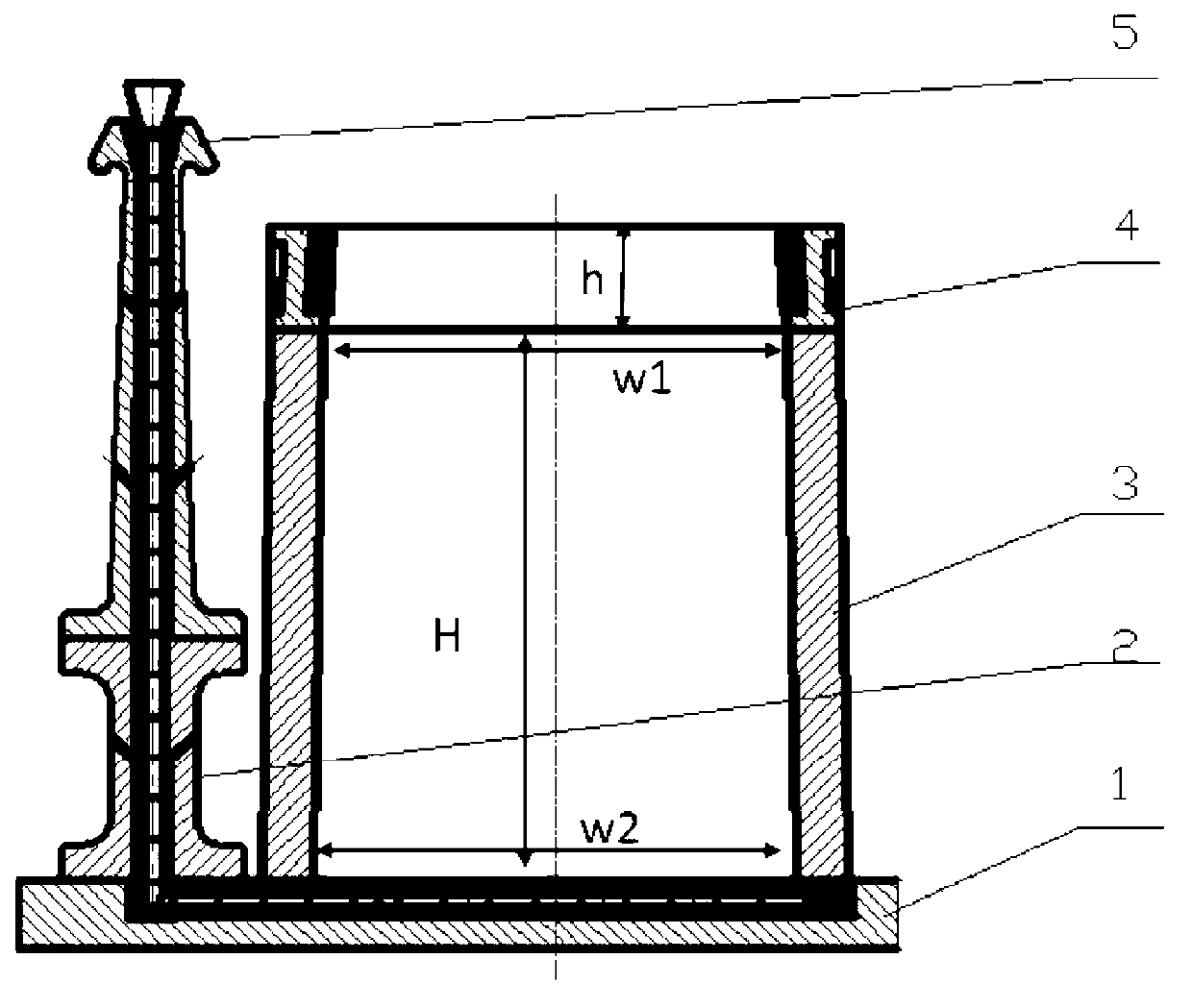

Image

Examples

Embodiment 1

[0032] In this embodiment, a large extra-thick slab with an overall size of about 650×2500×3400 mm and a single weight of about 40 tons (t) is produced by adopting the process described in the present invention. The specific process is as follows:

[0033] The material of the large extra-thick slab is 16Mn. When the molten steel is poured into the cavity of the metal mold for 1 hour, the thickness of the solidified shell of the large extra-thick slab is 100mm, and the thickness of the shell accounts for about 15% of the thickness of the large extra-thick slab. The thickness of the unsolidified area is 450 mm. At this time, high-temperature boxing is performed, and the outer surface temperature of the large extra-thick slab is as high as 1100 ° C. After high-temperature boxing, add an insulation cover to the outer surface of the large extra-thick slab to slowly cool the large extra-thick slab. Monitor the temperature of the outer surface of the large extra-thick slab. Freeze co...

Embodiment 2

[0036] In this embodiment, a large extra-thick slab with an external dimension of about 1000×2700×3300 mm and a unit weight of about 60 tons (t) is produced by adopting the process described in the present invention. The specific process is as follows:

[0037] The material of the large extra-thick slab is EH36. When molten steel is poured into the cavity of the metal mold for 2 hours, the thickness of the solidified shell of the large extra-thick slab is 200mm, and the thickness of the shell accounts for about 20% of the thickness of the large extra-thick slab. The thickness of the unsolidified area is 600mm. At this time, the high-temperature boxing is performed, and the outer surface temperature of the large extra-thick slab is as high as 1050°C. After high-temperature boxing, the outer surface of the large extra-thick slab is sprayed and forced to cool to monitor the temperature of the outer surface of the large extra-thick slab. The cooling rate is about 110°C / h until the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com