Clamp for machining motor end cover

A technology for motor end caps and fixtures, applied in metal processing mechanical parts, manufacturing tools, metal processing equipment, etc., can solve the problems of small production batches of end caps, poor repeat positioning accuracy of fixtures, and long time to adjust fixtures. The effect of saving the number and time of replacing the fixture, ensuring the processing accuracy requirements, and shortening the time of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

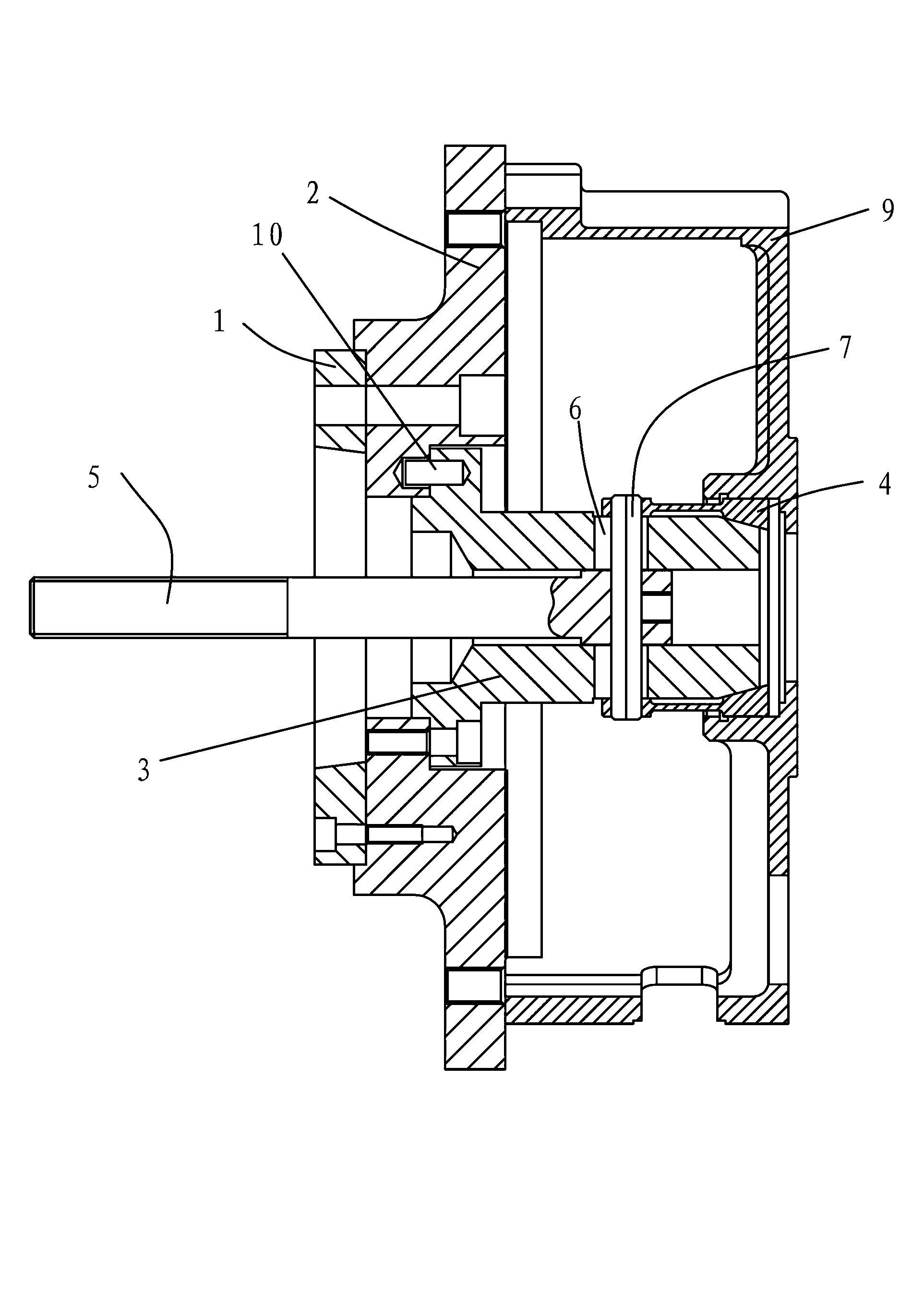

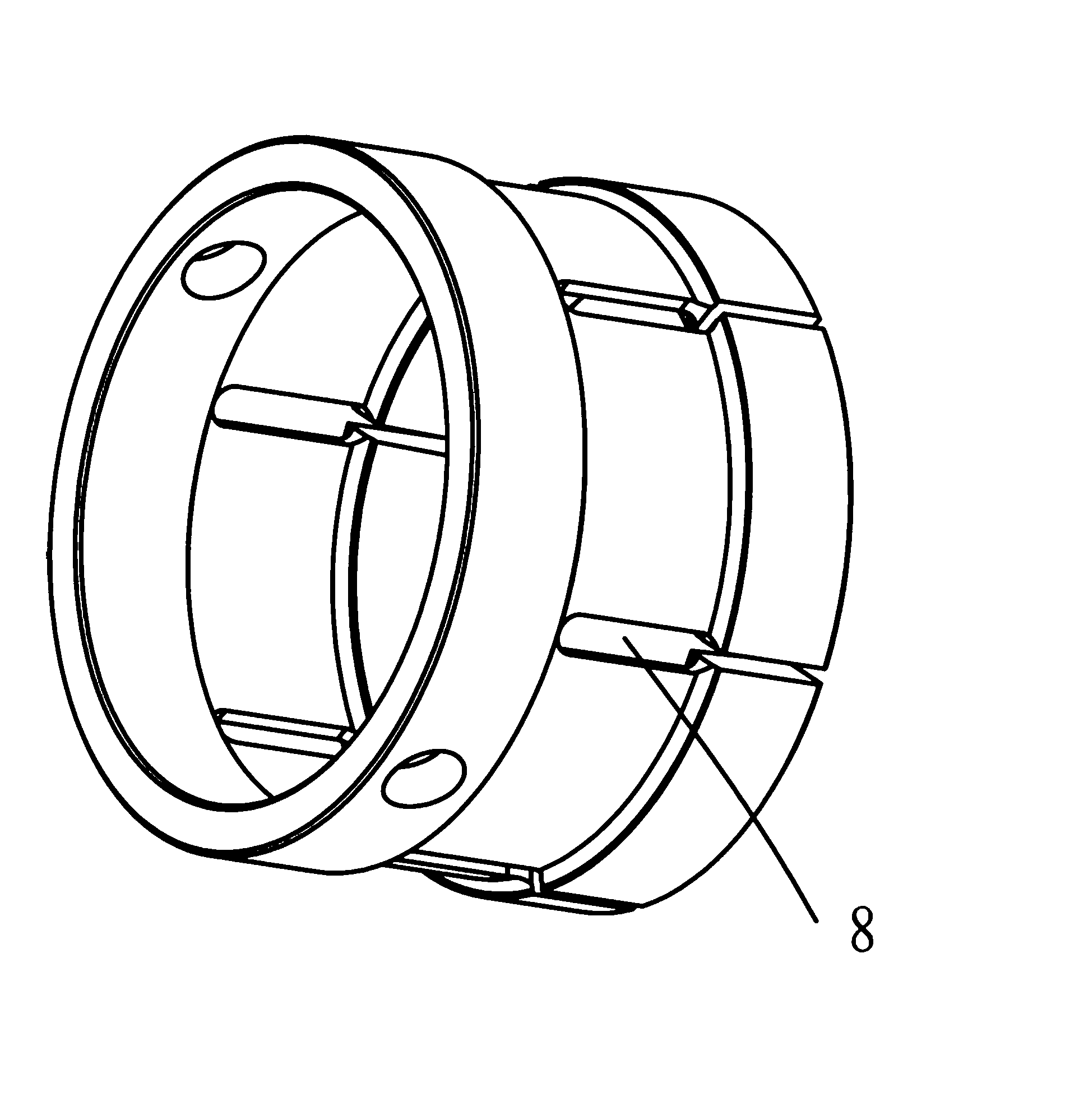

[0015] Example combination Figure 1 to Figure 2 , a fixture for processing motor end covers, including a flange 1, an end plate 2, a mandrel 3, a jacket 4 and a pull rod 5, the end plate 2 is axially hollow, the mandrel 3 is axially hollow, and the core The inner end of the shaft 3 is installed on the end plate 2, and the surface of the end plate and the mandrel are respectively provided with pin holes, and the positioning pins 10 are penetrated in the pin holes to connect the end plate 2 and the mandrel 3, so that the end plate 2 and the mandrel 3 are connected. The plate and the mandrel are positioned in the radial direction, and ensure that the mandrel 3 and the end plate 2 are on the same axis. The width in the axial direction of the mandrel 3 is greater than the diameter of the pin 7, so that the pin can move horizontally in the through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com