Precise linear cutting clamping device for titanium alloy weak-rigidity piece and working method of precise linear cutting clamping device

A technology of clamping device and working method, which is applied in the direction of accessory devices, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult to guarantee precision, high manufacturing cost, processing deformation of titanium alloy weak rigidity parts, etc., to improve precision and surface The effect of roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

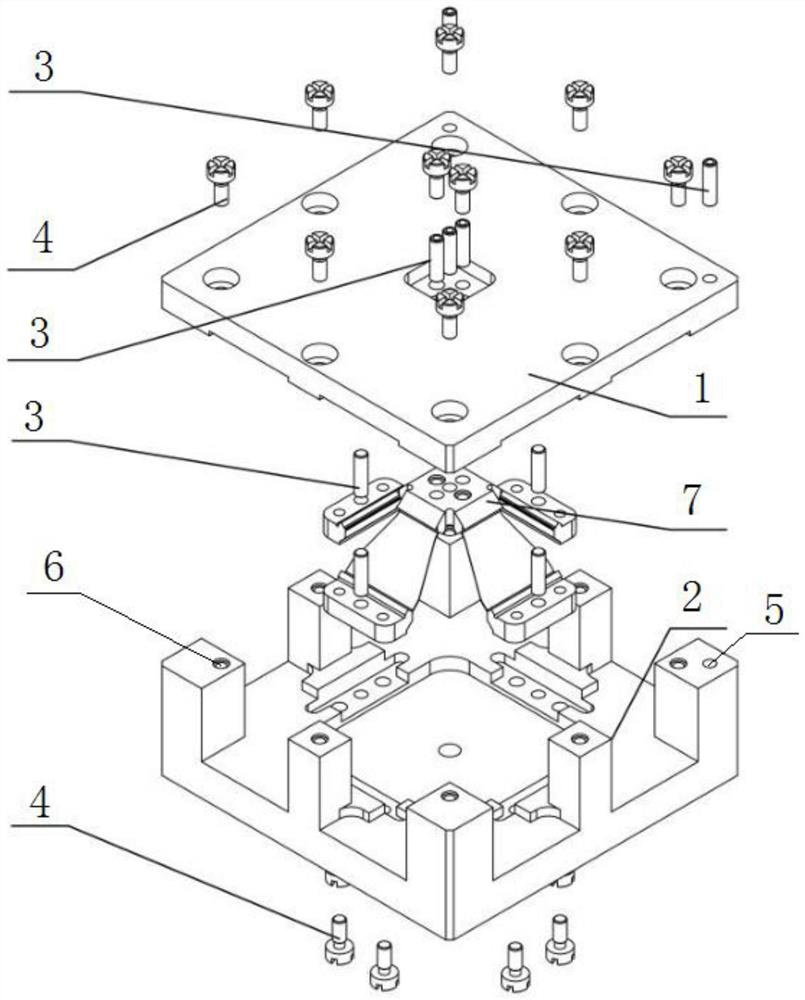

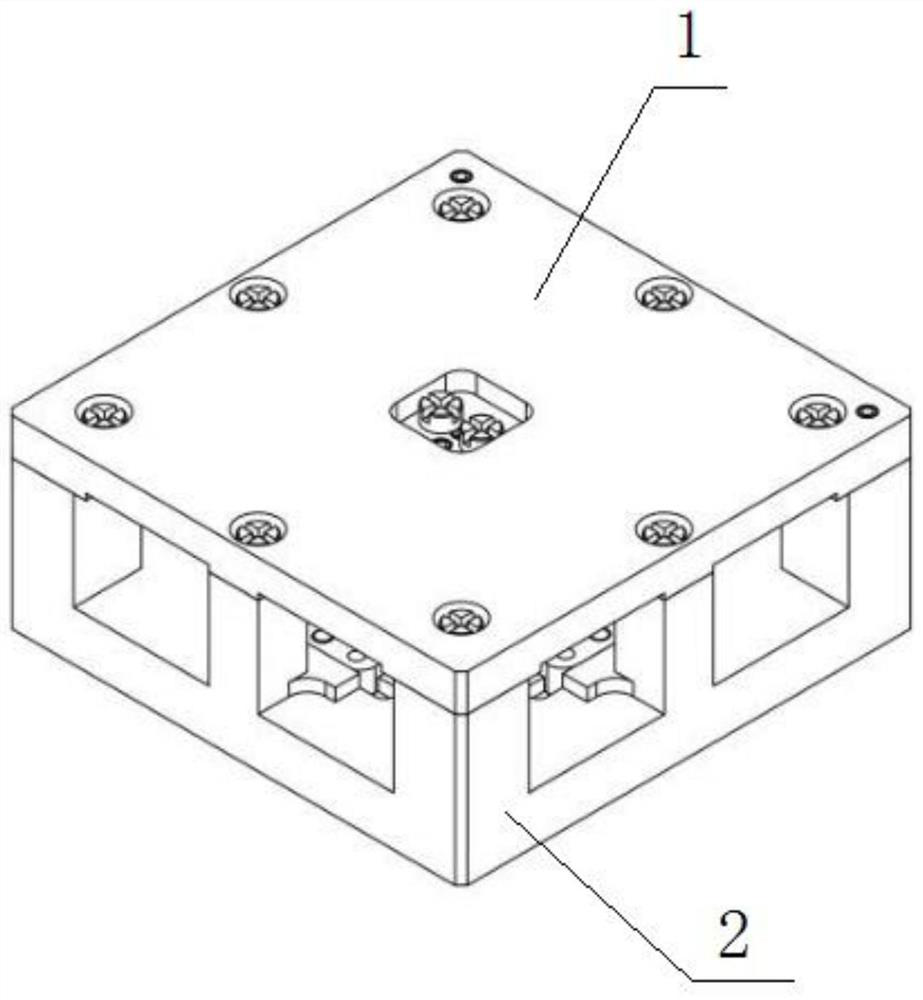

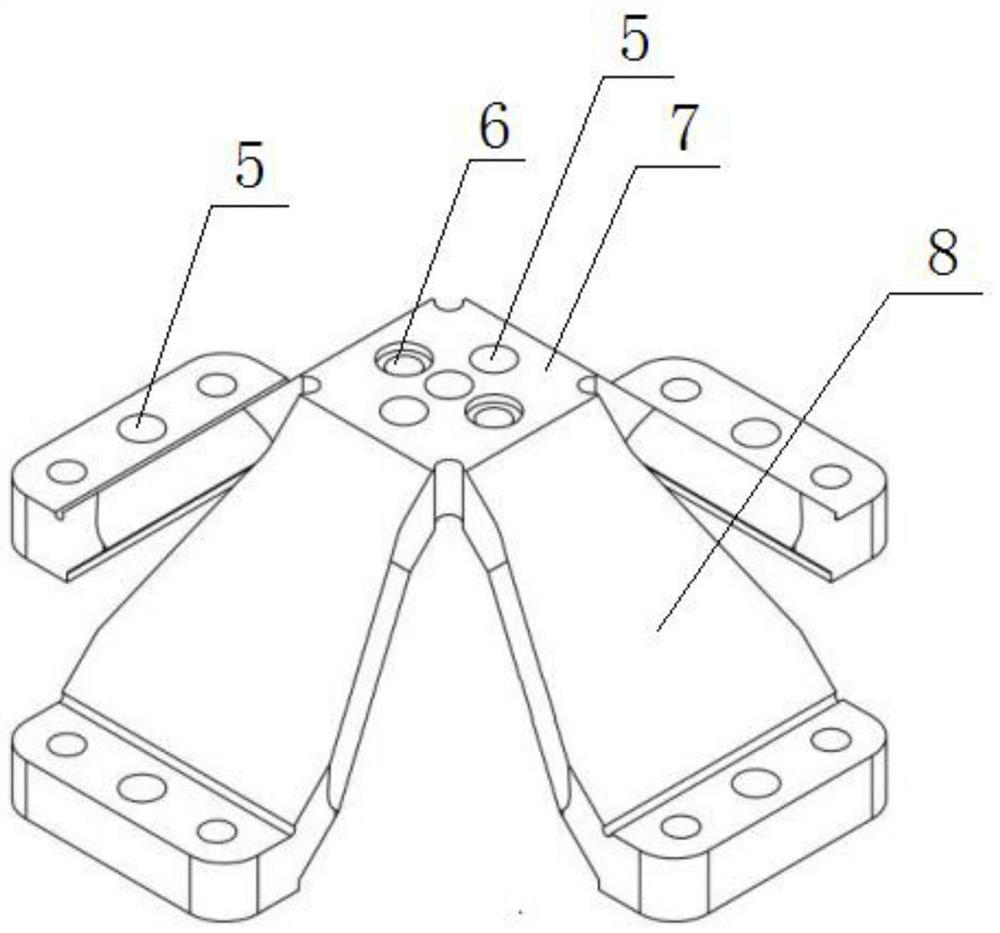

[0042]The precision wire cutting and clamping device for titanium alloy weak rigid parts, including the upper cover 1, the E-shaped lower cover 2, the positioning pin 3 and the fixing screw 4. The clamping device fixes the thin-walled part 7 and then cuts it in the slow wire The thickness of the wing plate 8 of the thin-walled part 7 is cut to a thickness of 0.2 mm on the machine tool. The thin-walled part 7 is a weak rigidity part made of titanium alloy; it has an upper plane 701 and a lower plane 703 and a wing plate 8 connecting the upper and lower planes in four directions.

[0043]The bottom surface of the E-shaped lower cover 2 has a plate-like structure, the upper edge of the bottom surface of the E-shaped lower cover 2 is provided with a positioning reference table 201, the side of the E-shaped lower cover 2 is Ш-shaped, and one of the two adjacent positioning reference tables 201 The space between is the gap 9 of the electrode wire cutting area. The E-shaped lower cover 2 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com