Device provided with stress monitoring equipment

A technology for monitoring equipment and installing stress, which is applied in the field of installing stress monitoring equipment, can solve problems such as increased loss of monitoring equipment, wrong stability judgments, and increased construction costs, so as to improve applicability, work efficiency, and accuracy , High installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

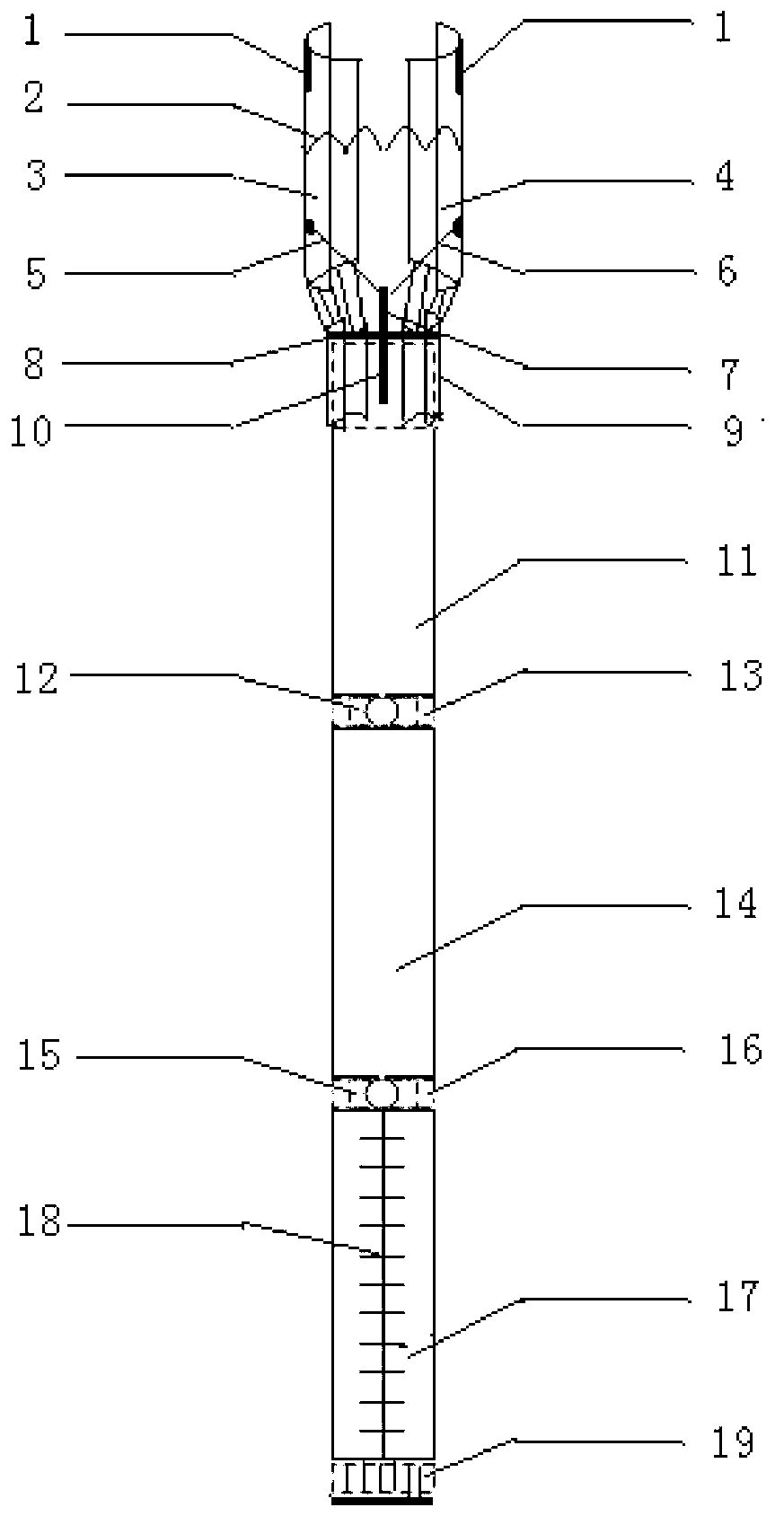

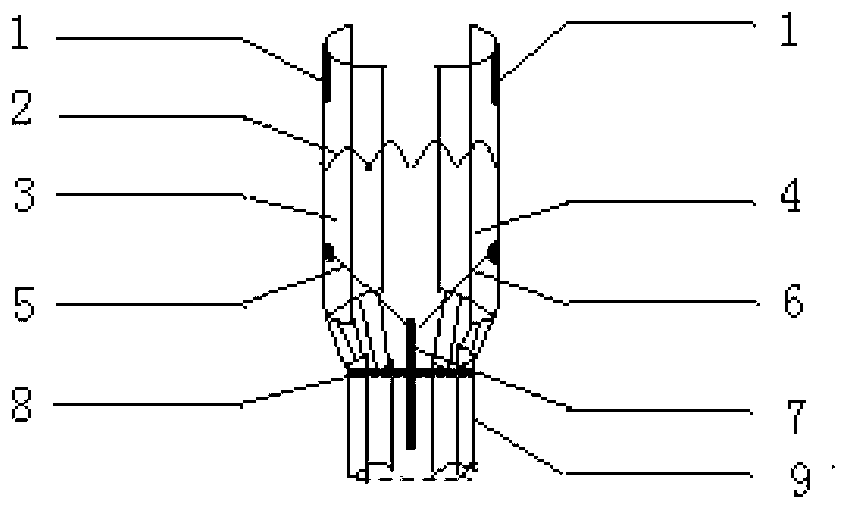

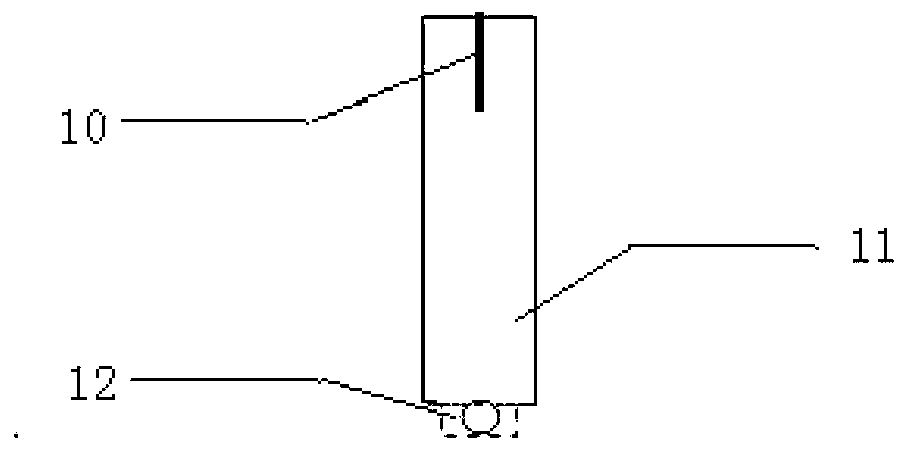

[0015] The main structure of this embodiment includes anti-friction gasket 1, elastic spring 2, left splint 3, right splint 4, skeleton left leg 5, skeleton right leg 6, skeleton bolt 7, chuck tail baffle 8, chuck tail cover Barrel 9, end mounting rod bolt 10, end mounting rod main body 11, end mounting rod lock 12, intermediate connecting rod front locking 13, intermediate connecting rod main body 14, intermediate connecting rod rear locking 15, tail mounting rod Lock buckle 16, tail mounting rod main body 17, tail mounting rod scale 18, tail mounting rod direction dial 19 and tail mounting rod direction hammer 20; two anti-friction gaskets 1 of symmetrical structure are respectively located on the left splint 3 and right splint 4 On the inside surface of the front section, the left splint 3 and the right splint 4 are symmetrical semi-arc structures, and the elastic spring 2 is fixedly connected between the left splint 3 and the right splint 4 to adjust the opening size of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com