Belted layer attaching drum of tyre building machine

A technology of tire building machine and belt layer, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of increased equipment cost, heavy weight, high spindle strength requirements, etc., and achieves convenient maintenance, convenient control, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

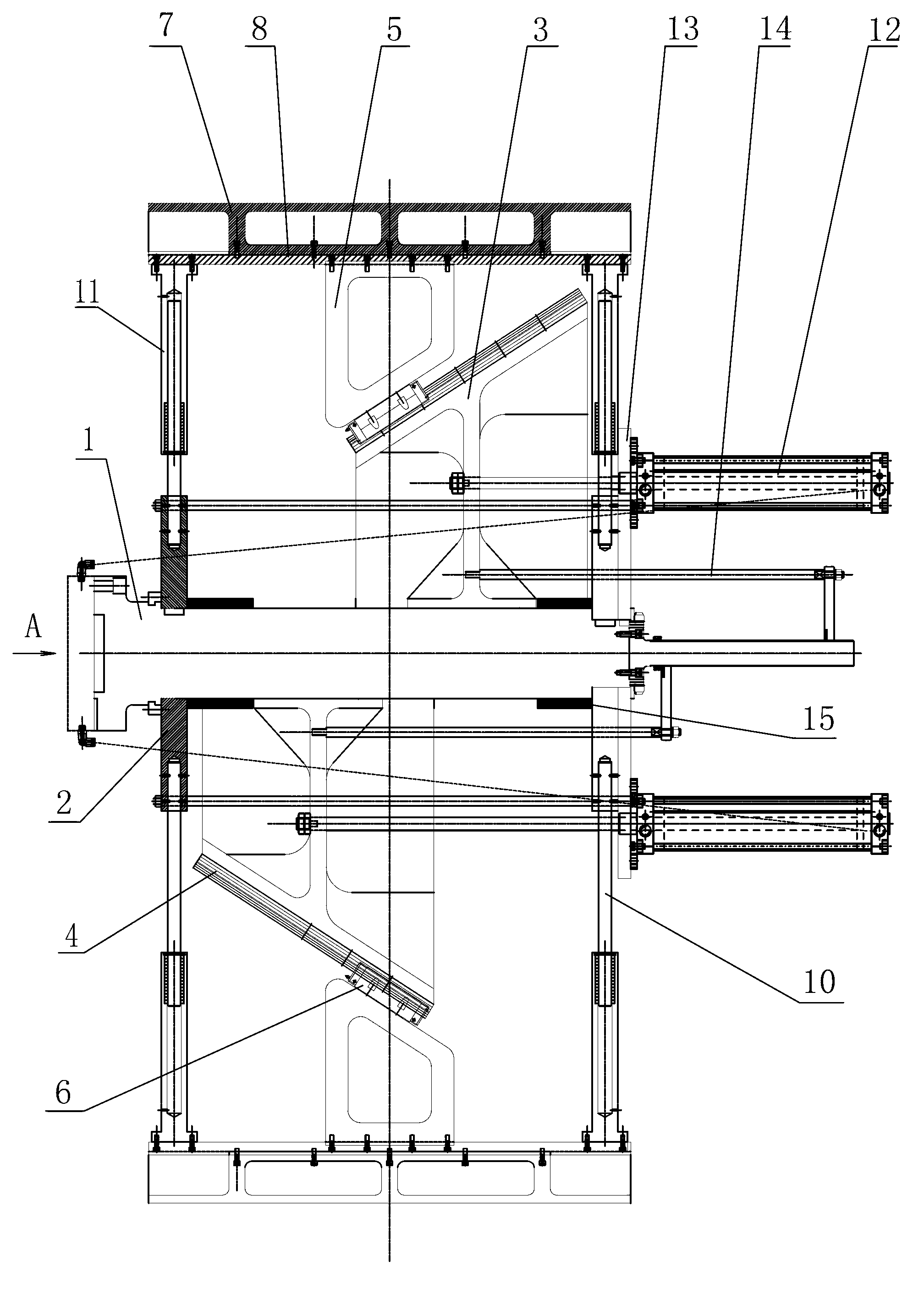

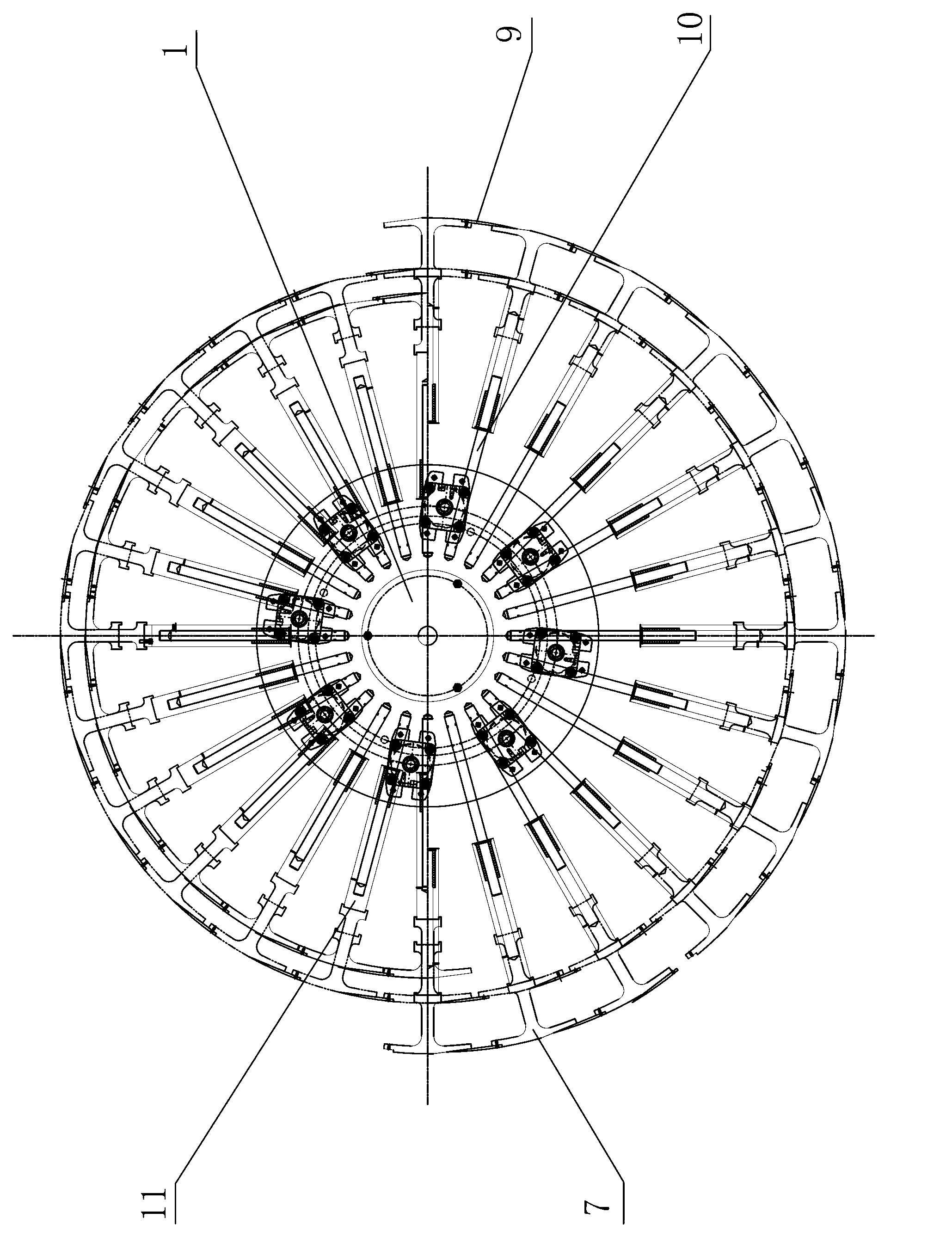

[0021] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

[0022] The belt laminating drum of the tire building machine of the present invention, its main body is an expansion and contraction device that radially and synchronously expands and contracts the drum block 7, and the expansion and contraction device includes a sliding shaft 1, an axle seat 2, a tapered sliding seat 3, The sliding pair formed by the linear guide rail 4 and the guide rail slider 6 , the support frame 5 and the mounting plate 8 and the guide mechanism formed by the guide sleeve 11 and the guide rod 10 .

[0023] The sliding shaft 1 is horizontally supported by shaft seats 2 at both ends (fixed screws are connected between the shaft seats 2 at both ends to ensure their relative positional relationship and parallelism), and the tapered sliding seat 3 is slidably installed on the sliding shaft 1 Above, the linear guide rails 4 are evenly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com