Vertical elevating device with deadweight balancing capability

A technology of vertical lifting and high capacity, applied in the direction of lifting devices, lifting frames, etc., can solve problems such as complex structure, failure to meet production requirements, poor stability, etc., and achieve the effects of simplified equipment structure, strong lifting load capacity, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

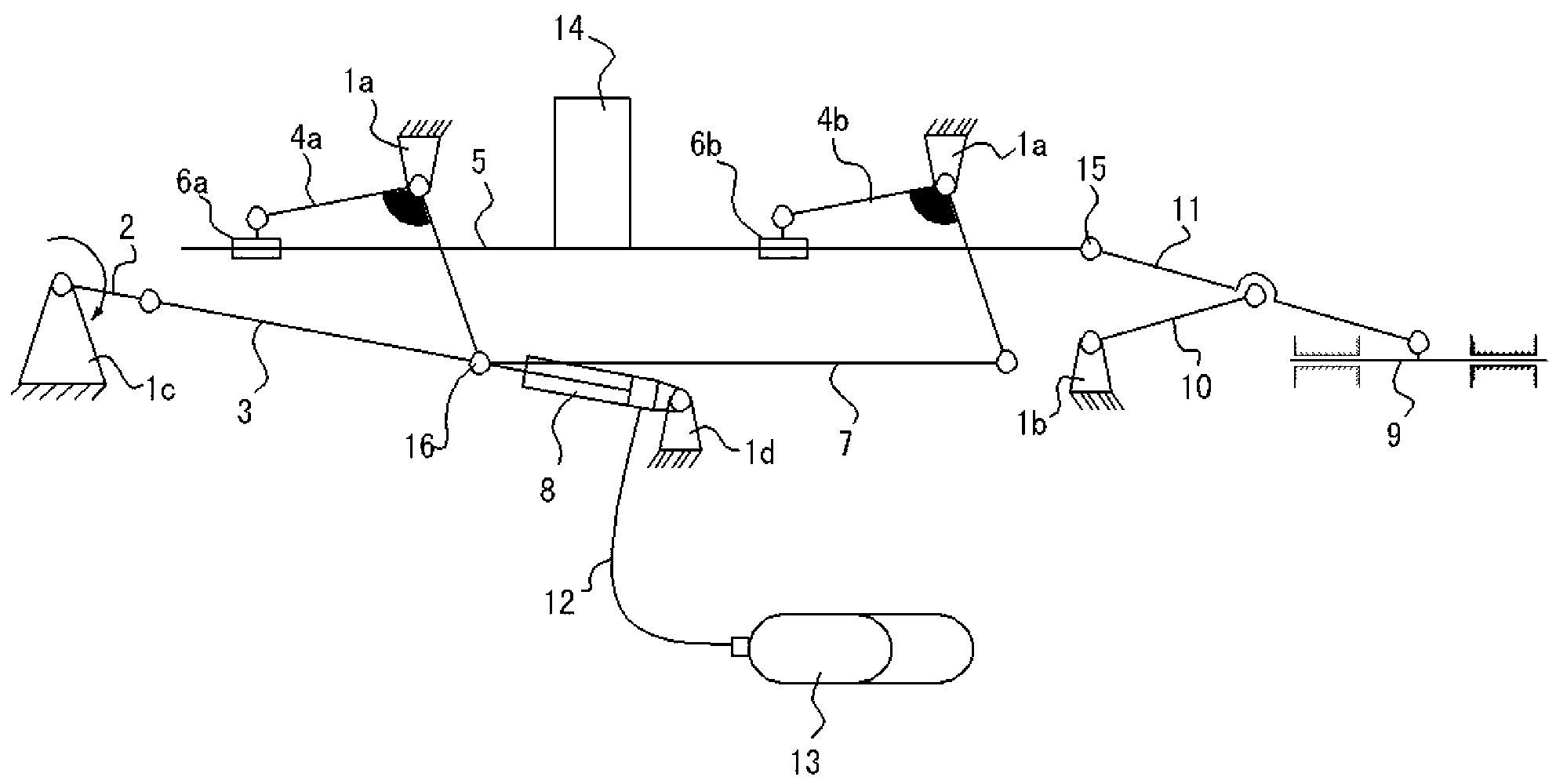

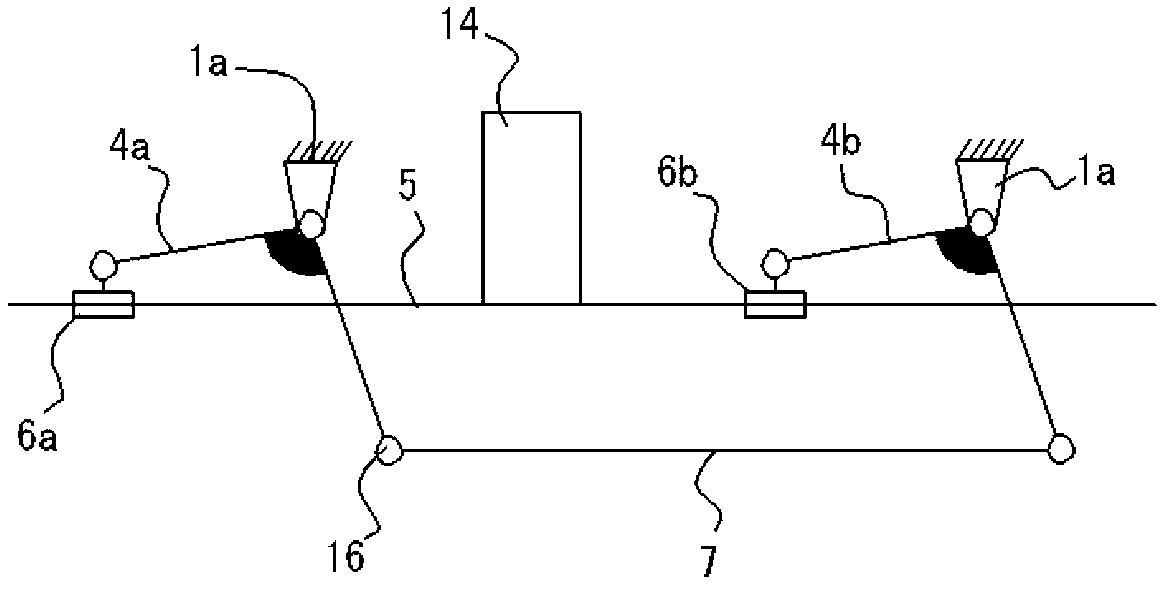

[0019] The structure of the vertical lifting device in the present embodiment is set to:

[0020] Such as figure 1 with figure 2 As shown, a parallelogram transmission mechanism is set, including: respectively hinge the first rocker 4a and the second rocker 4b on the top frame 1a on both sides; 7 connection, the outer rod ends of the first rocker 4a and the second rocker 4b are respectively provided with the first slider 6a and the second slider 6b at the same height, the first slider 6a and the second slider 6b It is connected with the horizontal lifting frame 5 as a sliding pair, and the carrier 14 is placed on the horizontal lifting frame 5;

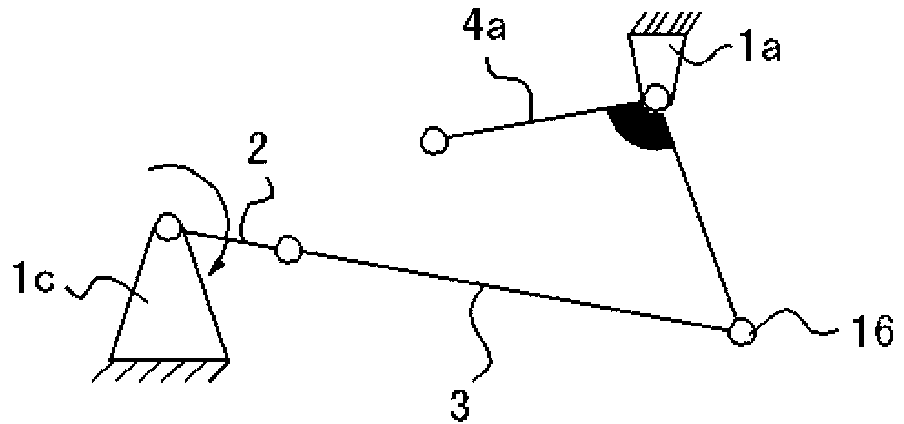

[0021] Such as figure 1 with image 3 As shown, the crank rocker mechanism set as the driving mechanism includes: one end of the connecting rod 3 is hinged with the crank 2 arranged on the crank frame 1c, and the other end of the connecting rod 3 is hinged with one end of the pull rod 7 to form a driving end hinge point 16;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com