Oil base drilling fluid filtrate reducer as well as preparation method and application of oil base drilling fluid filtrate reducer

An oil-based drilling fluid and fluid loss reducing agent technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of poor fluid loss reducing effect, not easy to biodegrade, and have biological toxicity, etc. Filtration reduction effect, low cost, good oil solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

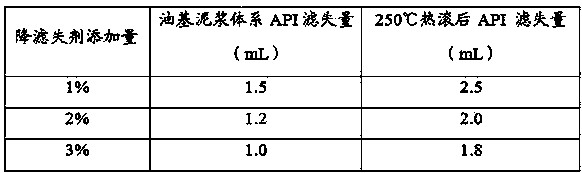

Embodiment 1

[0018] An oil-based drilling fluid fluid loss reducer, comprising the following components in parts by weight:

[0019] 70 parts of rubber powder; 30 parts of natural asphalt; 2 parts of superfine calcium carbonate.

[0020] The preparation process of the above-mentioned oil-based drilling fluid fluid loss reducer comprises:

[0021] Weigh rubber powder, natural asphalt and superfine calcium carbonate according to the above parts by weight, and feed these three raw materials to the winnowing pulverizer at the same time, keep mixing and pulverizing at a temperature of 18~30°C, and pass through a 60-mesh sieve That is, the oil-based drilling fluid fluid loss reducer is obtained.

[0022] Wherein, rubber powder, natural asphalt and superfine calcium carbonate are all common commercial products.

[0023] The obtained oil-based drilling fluid fluid loss reducer is a black powdery solid. After testing, its moisture content is 1.5%, and its oil soluble content is 98.2%.

[0024] ...

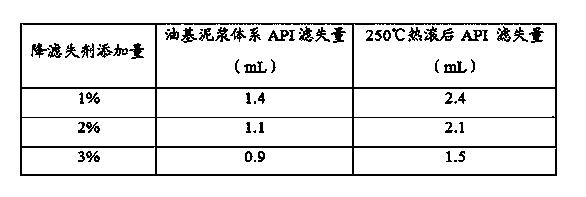

Embodiment 2

[0028] An oil-based drilling fluid fluid loss reducer, comprising the following components in parts by weight:

[0029] 80 parts of tire powder; 20 parts of natural asphalt; 5 parts of superfine calcium carbonate.

[0030] The preparation process of the above-mentioned oil-based drilling fluid fluid loss reducer comprises:

[0031] Weigh rubber powder, natural asphalt and superfine calcium carbonate according to the above parts by weight, and feed these three raw materials to the winnowing pulverizer at the same time, keep mixing and pulverizing at a temperature of 18~30°C, and pass through a 60-mesh sieve That is, the oil-based drilling fluid fluid loss reducer is obtained.

[0032] Among them, tire powder, natural asphalt and superfine calcium carbonate are all common commercial products.

[0033] The obtained oil-based drilling fluid fluid loss reducer is a black powdery solid. After testing, its moisture content is 1.1%, and its oil soluble content is 98.7%.

[0034] T...

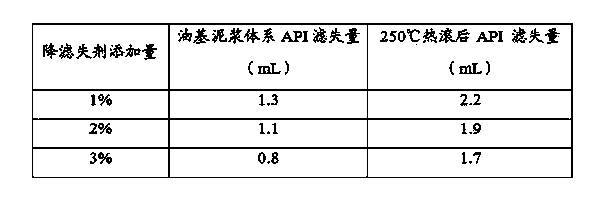

Embodiment 3

[0038] An oil-based drilling fluid fluid loss reducer, comprising the following components in parts by weight:

[0039] 90 parts of tire powder; 10 parts of natural asphalt; 8 parts of superfine calcium carbonate.

[0040] The preparation process of the above-mentioned oil-based drilling fluid fluid loss reducer comprises:

[0041] Weigh rubber powder, natural asphalt and superfine calcium carbonate according to the above parts by weight, and feed these three raw materials to the winnowing pulverizer at the same time, keep mixing and pulverizing at a temperature of 18~30°C, and pass through a 60-mesh sieve That is, the oil-based drilling fluid fluid loss reducer is obtained.

[0042] Among them, tire powder, natural asphalt and superfine calcium carbonate are all common commercial products.

[0043] The obtained oil-based drilling fluid fluid loss reducer is a black powdery solid. After testing, its moisture content is 1.2%, and its oil soluble content is 98.5%.

[0044] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com