Impervious fluid loss additive for petroleum well drilling

A fluid loss control agent, oil drilling technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problem of no non-permeable fluid loss control agent, achieve high recovery value, widen the density range, increase Effect of Formation Fracture Pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

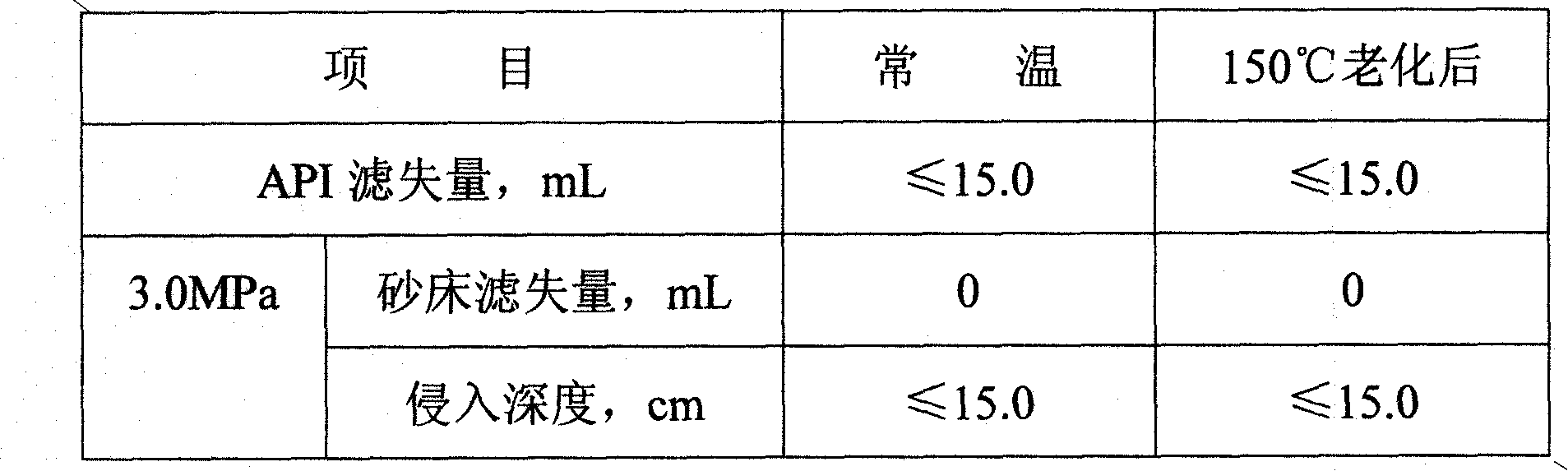

Image

Examples

Embodiment 1

[0012] Embodiment 1 (mass ratio)

[0013] First, the lignocellulose is pulverized to 0.074mm, and then the mass ratio of lignocellulose: silicon micropowder: polyurethane is 30: 40: 30 and stirred evenly to obtain the non-permeable fluid loss reducer for oil drilling. The product is in powder form. The prepared non-permeable fluid loss reducer for oil drilling can be added to the drilling fluid.

Embodiment 2

[0014] Embodiment 2 (mass ratio)

[0015] First, the lignocellulose is pulverized to 0.074mm, and then the mass ratio of lignocellulose: silicon micropowder: polyurethane is 35: 50: 15 and stirred evenly to obtain the non-permeable fluid loss reducer for oil drilling. The prepared non-permeable fluid loss reducer for oil drilling can be added to the drilling fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com