Anti-loose structure for connection of spool and valve rod

A valve stem and valve core technology, applied in valve devices, engine components, mechanical equipment, etc., can solve the problems of low assembly efficiency, high valve core processing requirements, and low reliability, so as to improve assembly efficiency and reduce processing difficulty. , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

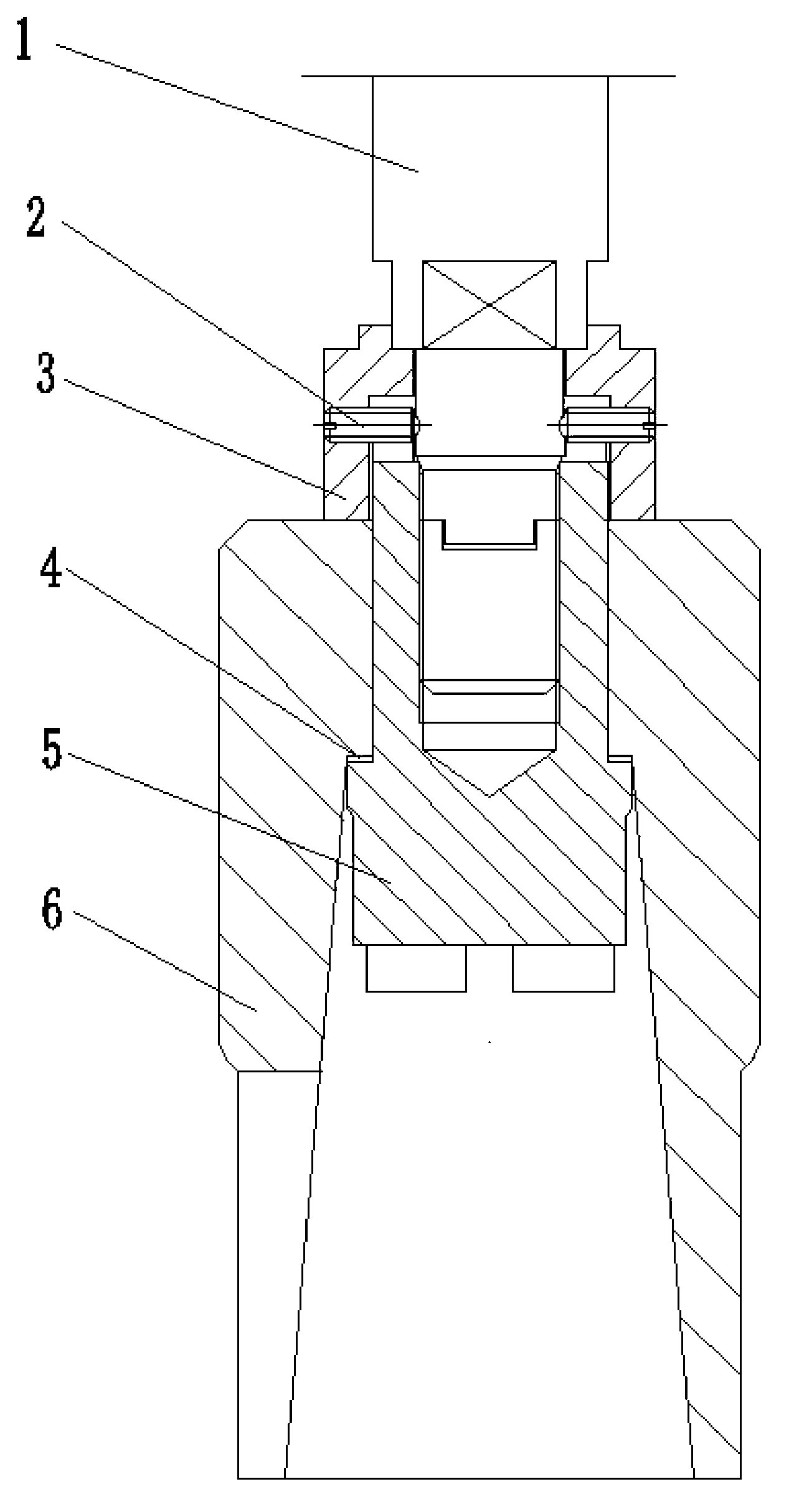

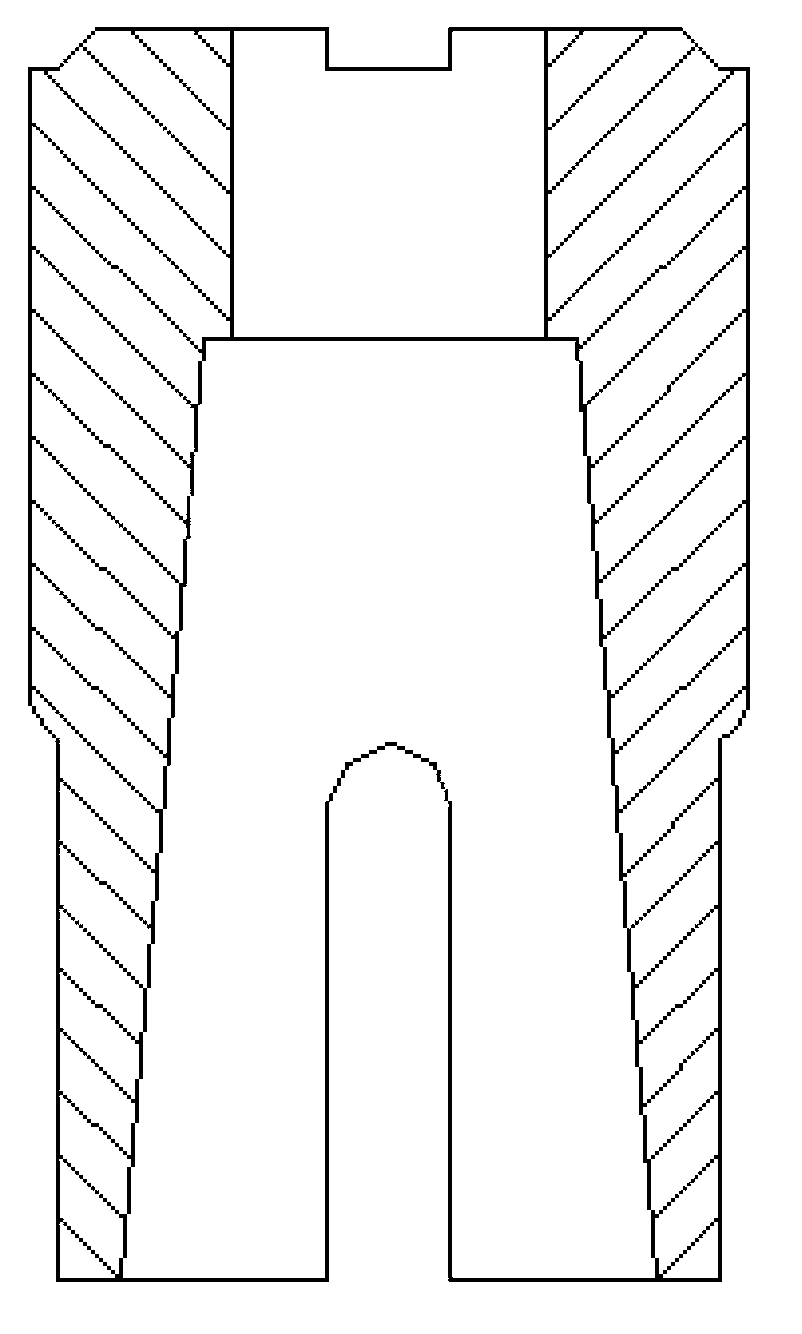

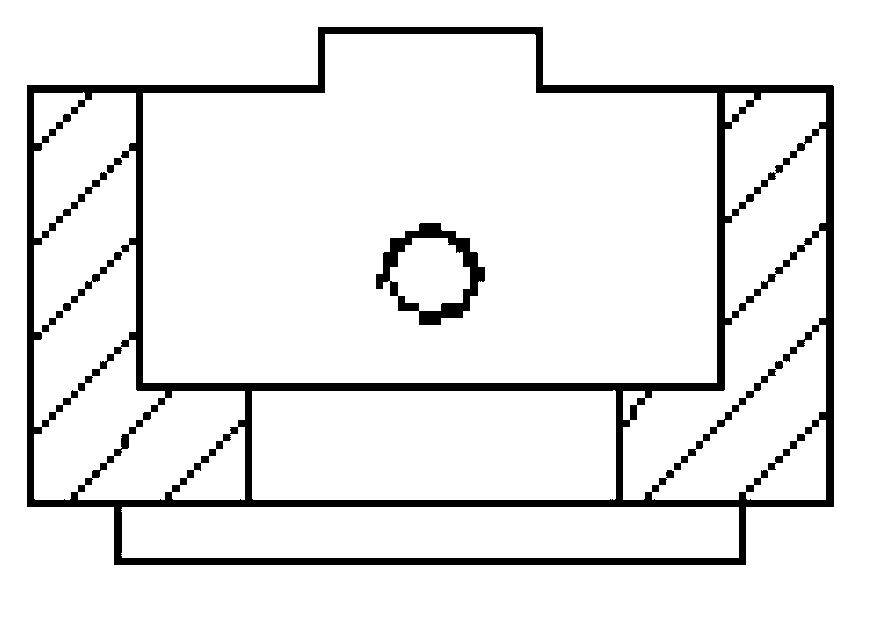

[0016] Such as figure 1 As shown, the present invention is an anti-loosening structure in which the valve core and the valve stem are connected, including the valve core 6 and the valve stem 1, and the lock nut 5 is sleeved on the valve stem 1, between the lock nut 5 and the valve stem 1 Threaded connection is adopted, and the lock nut 5 is located between the valve core 6 and the valve stem 1, and a boss cooperating with a step in the valve core 6 is provided under the lock nut 5, and the boss and the valve core 6 A sealing device is installed between the inner steps to prevent the medium from flowing out, specifically a gasket 4 is used.

[0017] It also includes an anti-rotation sleeve 3, the anti-rotation sleeve 3 is set on the lock nut 5 and the valve stem 1 at the same time, and the upper part of the anti-rotation sleeve 3 and the valve stem 1 are locked together by concave-convex fit, and its lower part is connected to the valve stem 1. The cores 6 are also clamped to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap