Plastic pre-embedded pipe, solar water heater plastic liner using the pre-embedded pipe and production method

A technology of solar water heaters and pre-embedded pipes, which is applied in the direction of solar thermal power generation, solar thermal devices, pipes/pipe joints/pipe fittings, etc., which can solve the problems of the plastic liner and pipe fittings of solar water heaters not being tightly combined and achieve good chemical stability , tight combination and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The raw material components and weight percentages of the polypropylene modified material for producing plastic pre-embedded pipes and plastic liners are:

[0056] Polypropylene: 70%, Glass Fiber: 21%, Calcium Carbonate: 2%, Dilauryl Ester: 2%, Zinc Oxide: 2%, Fixative: 3%.

[0057] The production method of the plastic liner of the solar water heater adopting the plastic pre-embedded pipe comprises the following steps:

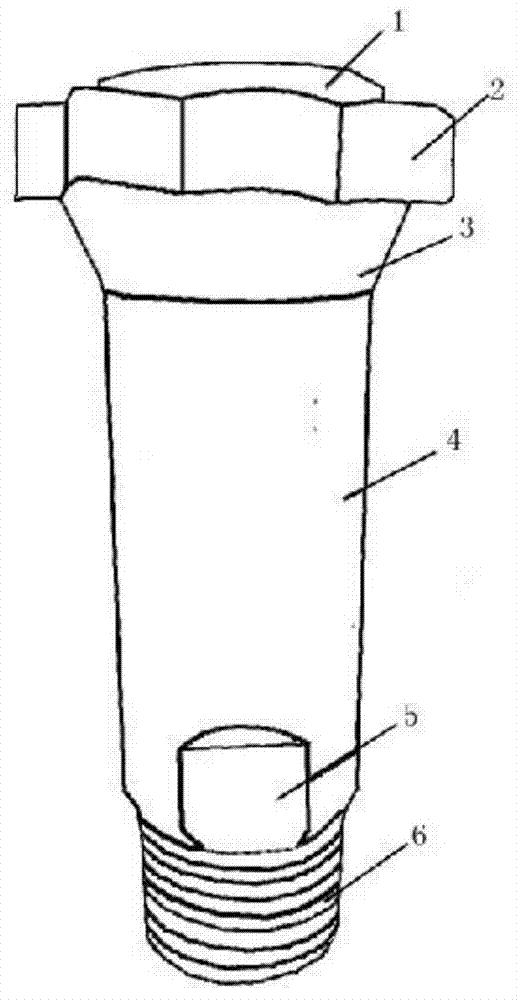

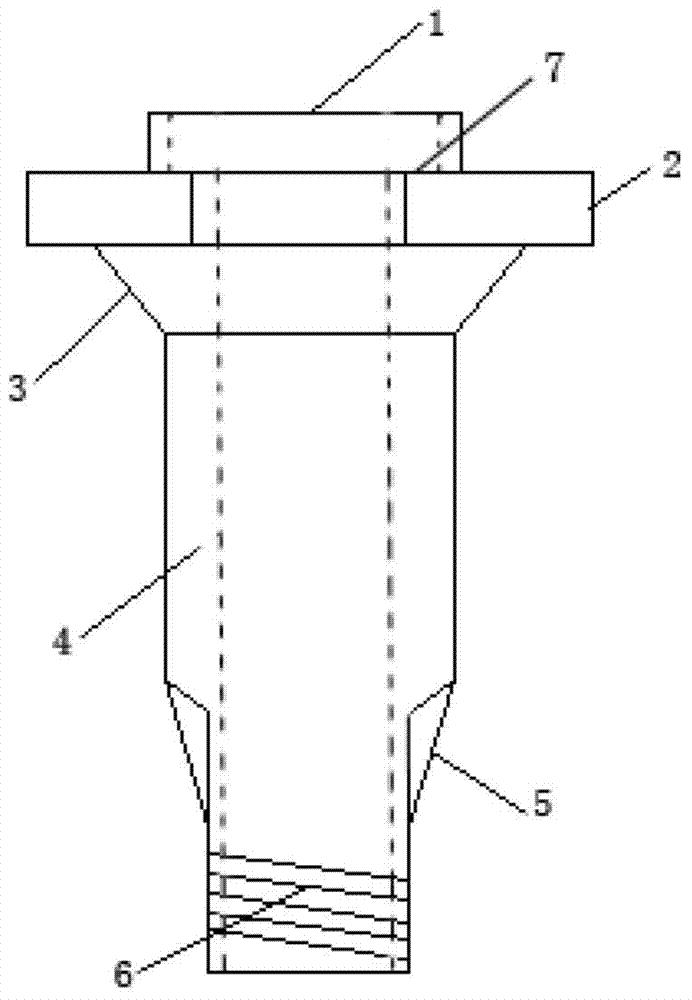

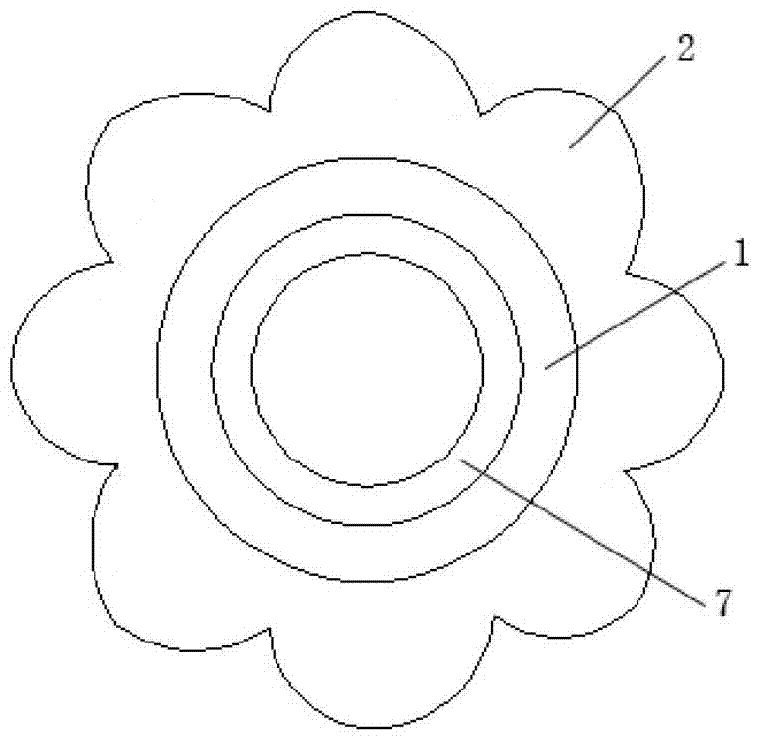

[0058] 1) Forming of plastic embedded pipe:

[0059] Put the raw material of polypropylene modified material into the mixer according to the ratio, and mix it at 80°C for 10 hours; feed it through the screw extruder, put the mixed material into the hot-melt pipeline, and melt it at 200°C for 10 hours ;Close the mold, let the mixed material in the hot-melt pipeline enter the mold, and then blow air in the mold to make the mixed material fill the entire mold cavity. The temperature in the mold is 200°C, the pressure is 5MPa, and the control is 20 minutes...

Embodiment 2

[0066] The raw material components and weight percentages of the polypropylene modified material for producing plastic pre-embedded pipes and plastic liners are:

[0067] Polypropylene: 46%, Glass Fiber: 28%, Calcium Sulfate: 6%, Ditetradecyl Ester: 6%, Iron Oxide Red: 7%, Fixative: 7%.

[0068] The production method of the plastic liner of the solar water heater adopting the plastic pre-embedded pipe comprises the following steps:

[0069] 1) Forming of plastic embedded pipe:

[0070] Put the raw material of polypropylene modified material into the mixer according to the ratio, and mix it at 70°C for 8 hours; feed it through the screw extruder, put the mixed material into the hot-melt pipeline, and melt it at 150°C for 8 hours ;Close the mold, let the mixed material in the hot-melt pipeline enter the mold, and then blow air in the mold to make the mixed material fill the entire mold cavity, the temperature in the mold is 150°C, the pressure is 3MPa, control for 10 minutes; n...

Embodiment 3

[0077] The raw material components and weight percentages of the polypropylene modified material for producing plastic pre-embedded pipes and plastic liners are:

[0078] Polypropylene: 50%, glass fiber: 28%, calcium chloride: 5%, trioctyl ester: 5%, benzophenones: 7%, fixative: 5%.

[0079] The production method of the plastic liner of the solar water heater adopting the plastic pre-embedded pipe comprises the following steps:

[0080] 1) Forming of plastic embedded pipe:

[0081] Put the raw material of polypropylene modified material into the mixer according to the ratio, and mix it at 60°C for 5 hours; feed it through the screw extruder, put the mixed material into the hot-melt pipeline, and melt it at 180°C for 5 hours ;Close the mold, let the mixed material in the hot-melt pipeline enter the mold, and then blow air in the mold to make the mixed material fill the entire mold cavity, the temperature in the mold is 180°C, the pressure is 2MPa, control for 20 minutes; natur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| deformation rate | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com