Pressure-bearing type plastic liner, production method and solar water heater using liner

A pressurized inner tank technology, applied in solar thermal power generation, solar thermal devices, heating devices, etc., can solve the problems of short life of enamel inner tanks, easy to produce rust, etc., to avoid plastic fiber breakage, save energy, The effect of saving process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below.

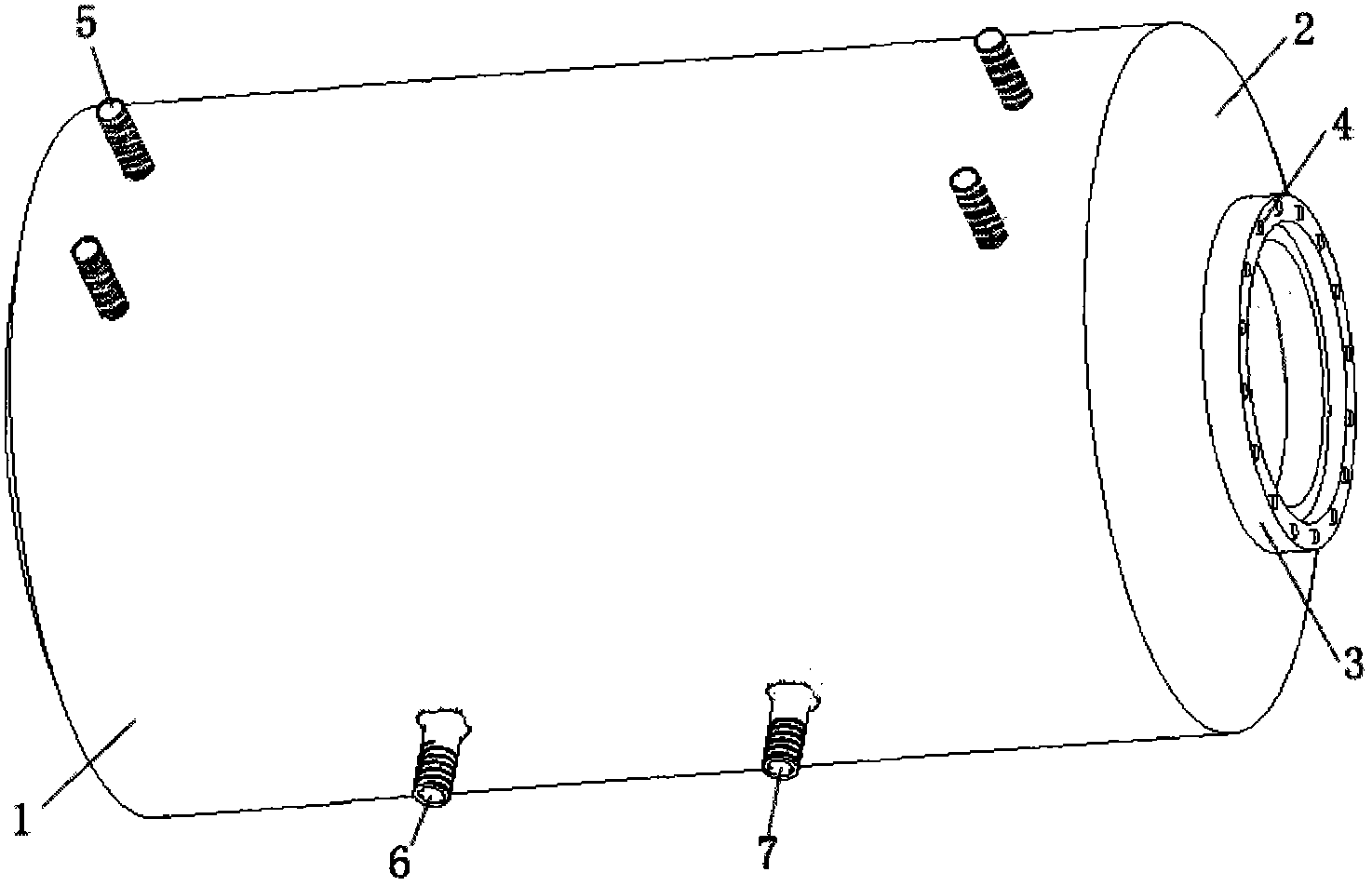

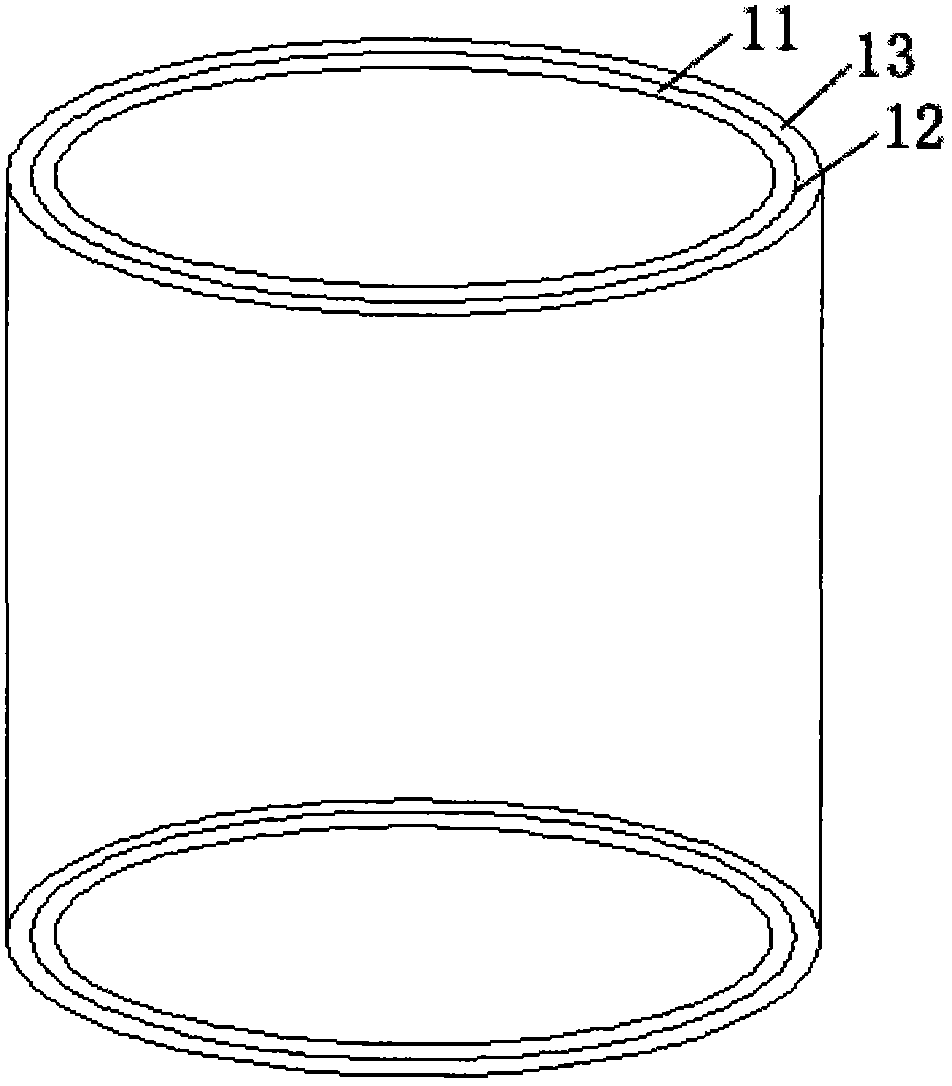

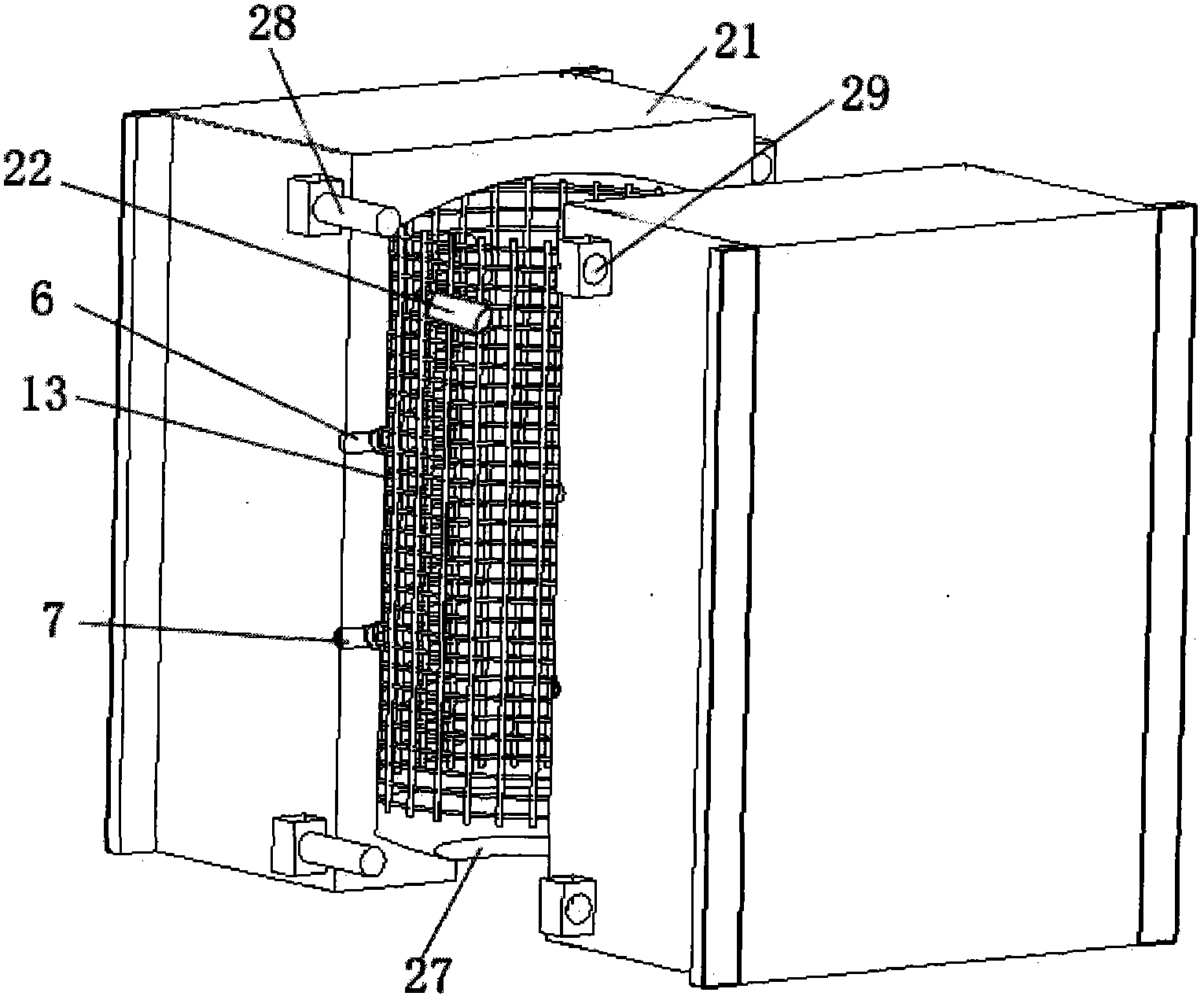

[0031] Such as Figure 1-2 As shown, the pressure-bearing plastic liner includes the liner body 1 and the end caps on both sides of the liner body 1. The liner body includes a first plastic layer 11, a mesh rib 12, and a second plastic layer 13 from the inside to the outside. , the end cap is made of plastic.

[0032] The plastic layer and the end cap are made of polypropylene modified material, and the reticulated ribs 12 are steel wire mesh.

[0033] A positioning ring 3 is pre-embedded at 2 places of one side end cover, and there is a circle of silk holes 4 connected with the auxiliary heating device on the positioning ring 3 .

[0034] The connector 5 that the plastic liner is fixed on the wall is pre-embedded on the circumference surface of the liner body 1 .

[0035] The connectors 5 are studs, and the number is four.

[0036] A water inlet pipe 6 and a water outlet pipe 7 are pre-embedded at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com