Pressure-adaptive continuous drainer for gas conveying pipeline

A transmission pipeline, self-adaptive technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems that do not meet the requirements of energy saving and environmental protection, and achieve the effect of large pressure bearing capacity and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

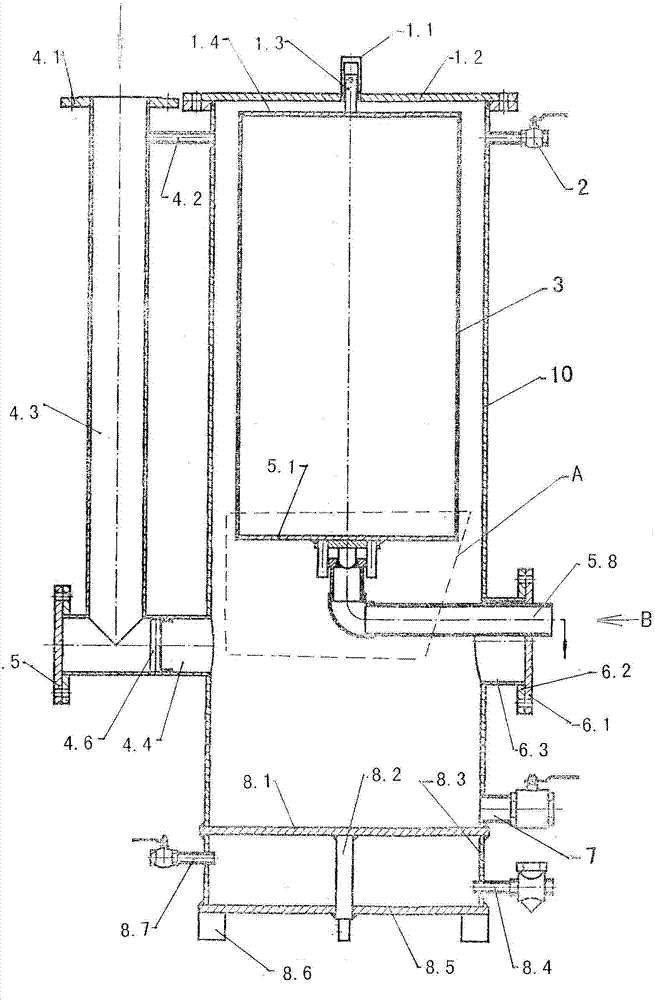

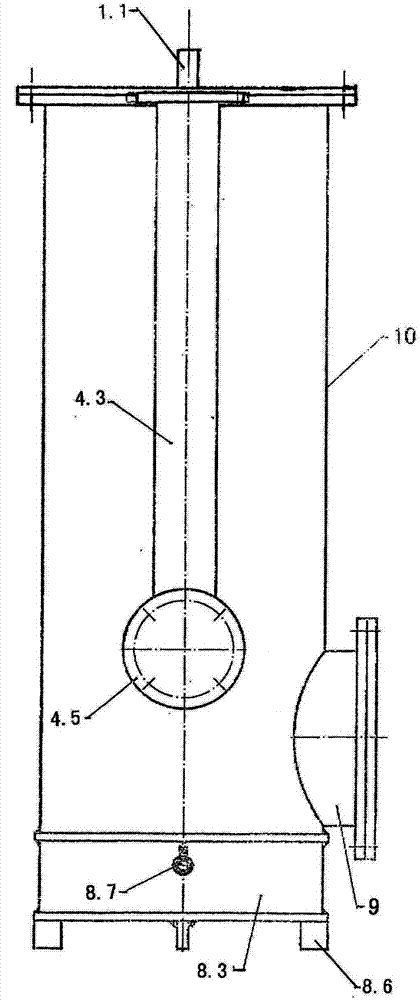

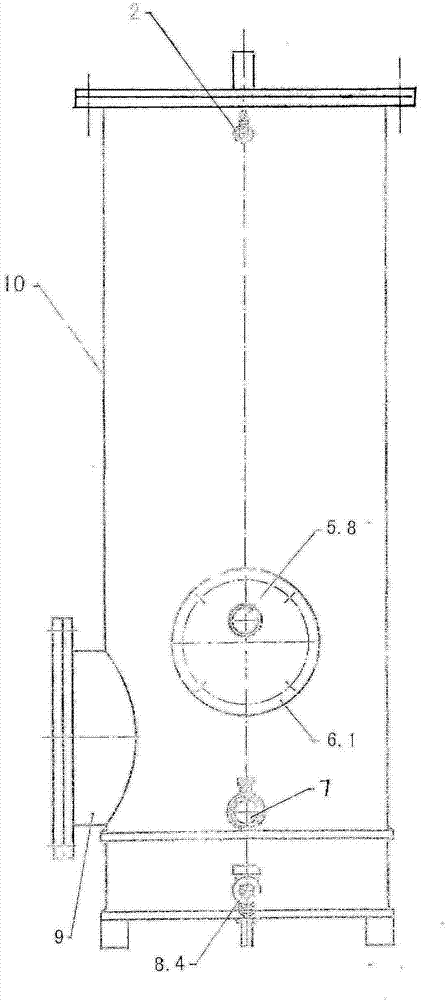

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] (Such as figure 1 As shown), a pressure-adaptive gas delivery pipeline continuous drainer includes a drainer upper cover assembly, a fault diagnosis valve 2, a drainer buoy assembly, a drainer inlet pipe assembly, a sealing body assembly, a movable drain pipe assembly, Sewage pipe 7, steam heating chamber assembly, inspection hole (assembly) 9 and main cylinder body 10, wherein the drainer upper cover assembly is composed of an upper guide sleeve 1.1, an upper cover plate 1.2 and a guide rod 1.3; the drainer buoy assembly is composed of a buoy body 3. The buoy upper end plate 1.4 and the buoy lower end plate 5.1 are formed. The buoy upper end plate 1.4 and the buoy lower end plate 5.1 are fixedly connected to the upper and lower ends of the buoy body 3 respectively to form a floating body. The shape of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com