Ceiling fixing fastener assembly for LED (Light Emitting Diode) lamp

A technology of LED lamps and fixing buckles, which is applied to the parts of lighting devices, lighting devices, light sources, etc., can solve the problems of inconvenient disassembly, etc., and achieve the effect of easy installation, quick disassembly, and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

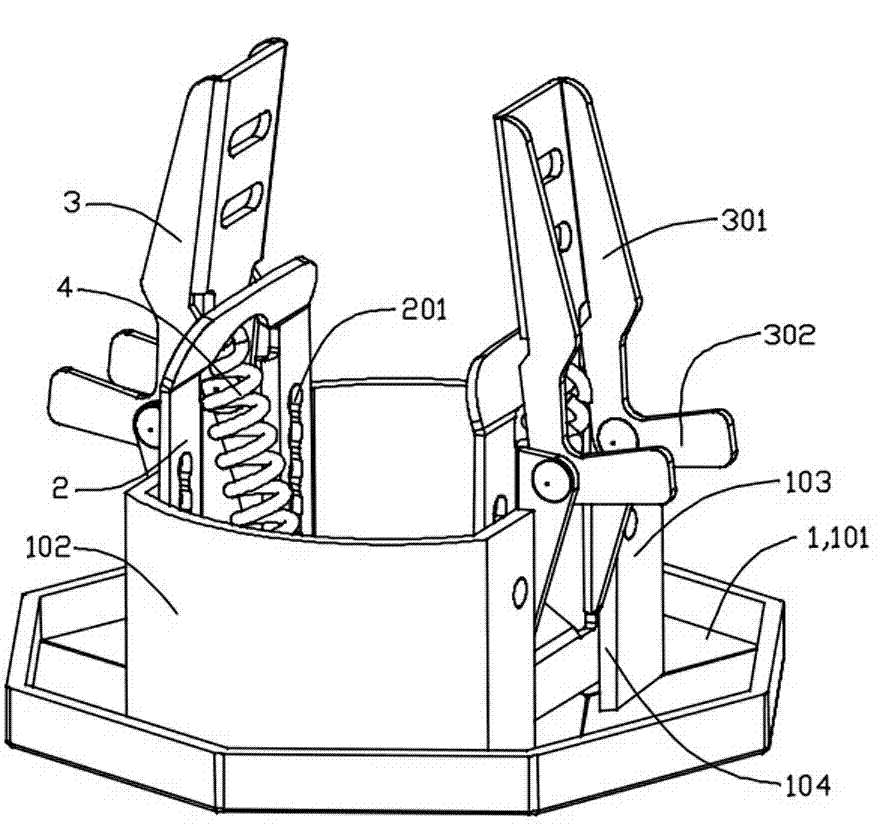

[0025] see figure 1 and Figure 8 , a ceiling fixing buckle assembly for an LED lamp, comprising a decorative cover 1, a fixing plate 2 arranged on the decorative cover 1, a fixing buckle 3 pivotally connected to the fixing plate 2, and the fixing buckle 3 in the installation position and the locking position Overturned elastic element 4. In this embodiment, the elastic element 4 is a tension spring.

[0026] The decorative cover 1 is provided with a face ring 101 that can cover the ceiling 5 mounting holes and a wall ring 102 that stretches into the ceiling 5 mounting holes. The two opposite sides of the wall ring 102 are provided with flat installation parts 103. A mounting groove 104 is provided in the middle.

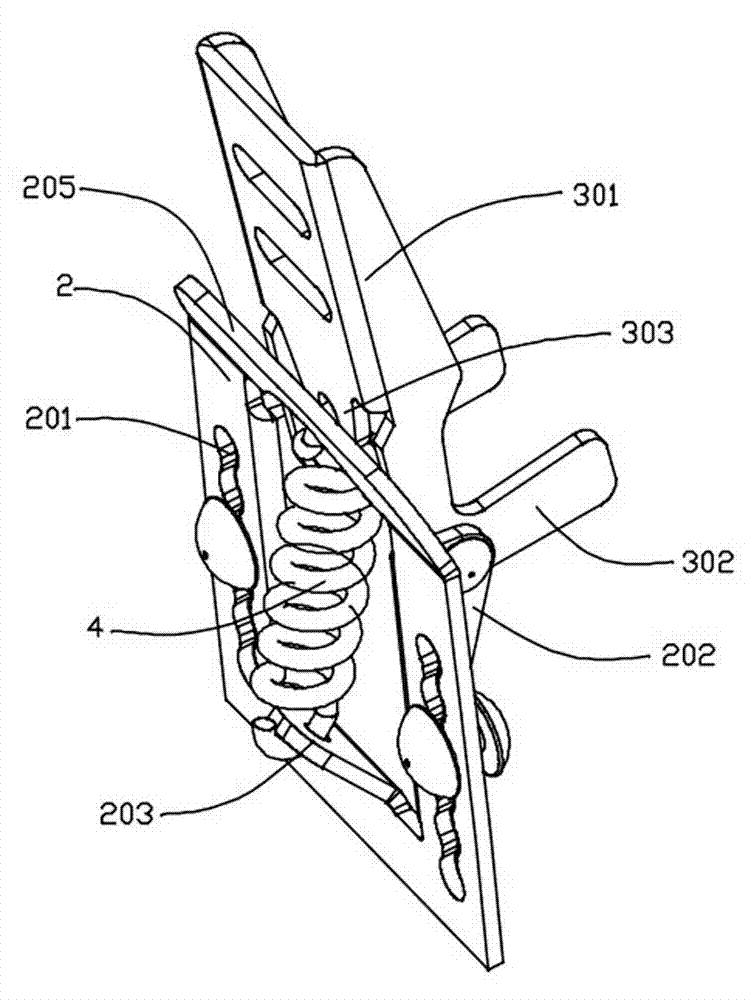

[0027] see figure 2 and image 3 In the middle of the fixed plate 2, there is an overturning groove 204, on both sides of the overturning groove 204 there are two pivotal support plates 202 extending outward, and on the fixed plate 2 on both sides of the pivot...

Embodiment 2

[0035] In this embodiment, the elastic element 4 is a compression spring, so except that the elastic element 4 and the installation structure of the elastic element 4 are slightly different, the others are the same as the first embodiment.

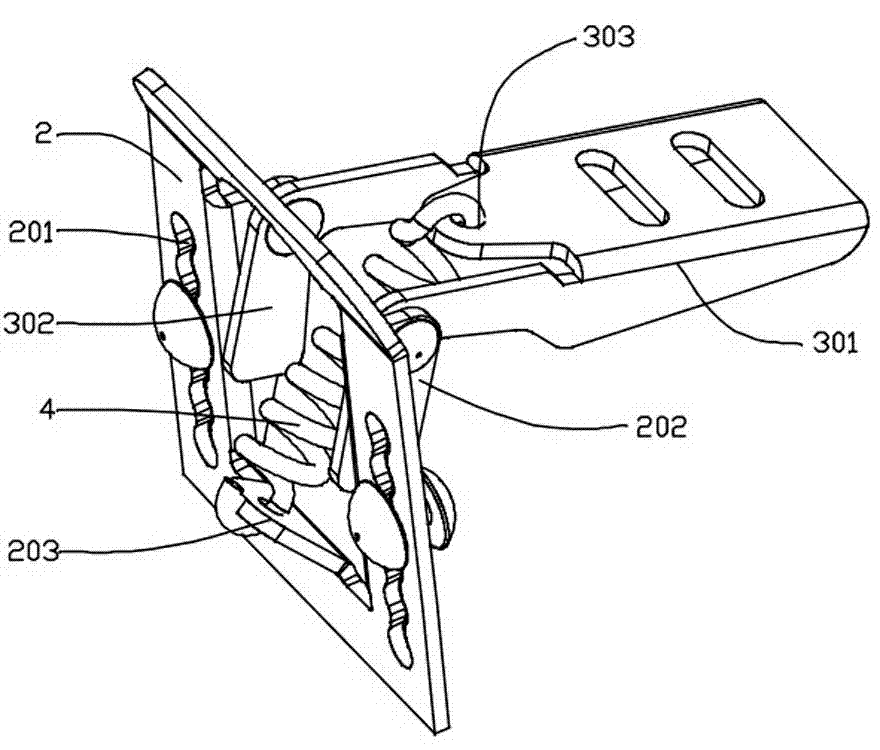

[0036] see Figure 5 , in this embodiment, since the elastic element 4 is a compression spring, in order to turn over the fixing buckle 3, the upper fixing tongue 303 on the fixing buckle 3 extends to the opposite side of the buckling part 301 of the fixing buckle 3 on the pivot axis. end. For the settings of the first flip angle α1 and the second flip angle α2, see Figure 7 .

[0037]

Embodiment 3

[0039] In this embodiment, the elastic element 4 is a torsion spring, so except that the elastic element 4 and the installation structure of the elastic element 4 are slightly different, the others are the same as the first embodiment.

[0040] see Figure 6 , in this embodiment, the torsion spring is installed on the upper part of the back side of the fixed plate opposite to the pivotal support plate 202 through a pin shaft. The upper fixing tongue 303 on the fixing buckle 3 is substantially the same as that in the second embodiment, and is also located at the other end of the crimping portion relative to the pivot axis of the fixing buckle. The settings of the first flip angle α1 and the second flip angle α2 also refer to Figure 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com