Assembling structure for air outlet shell and wheel disc of automobile air conditioner

A technology for air outlet housings and automotive air conditioners, applied to airflow control elements and other directions, can solve the problems of unbalanced force on the roulette, occupying a lot of axial space, and large shaking of the roulette, so as to achieve less occupied volume and reduce wear and tear. , The effect of easy and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

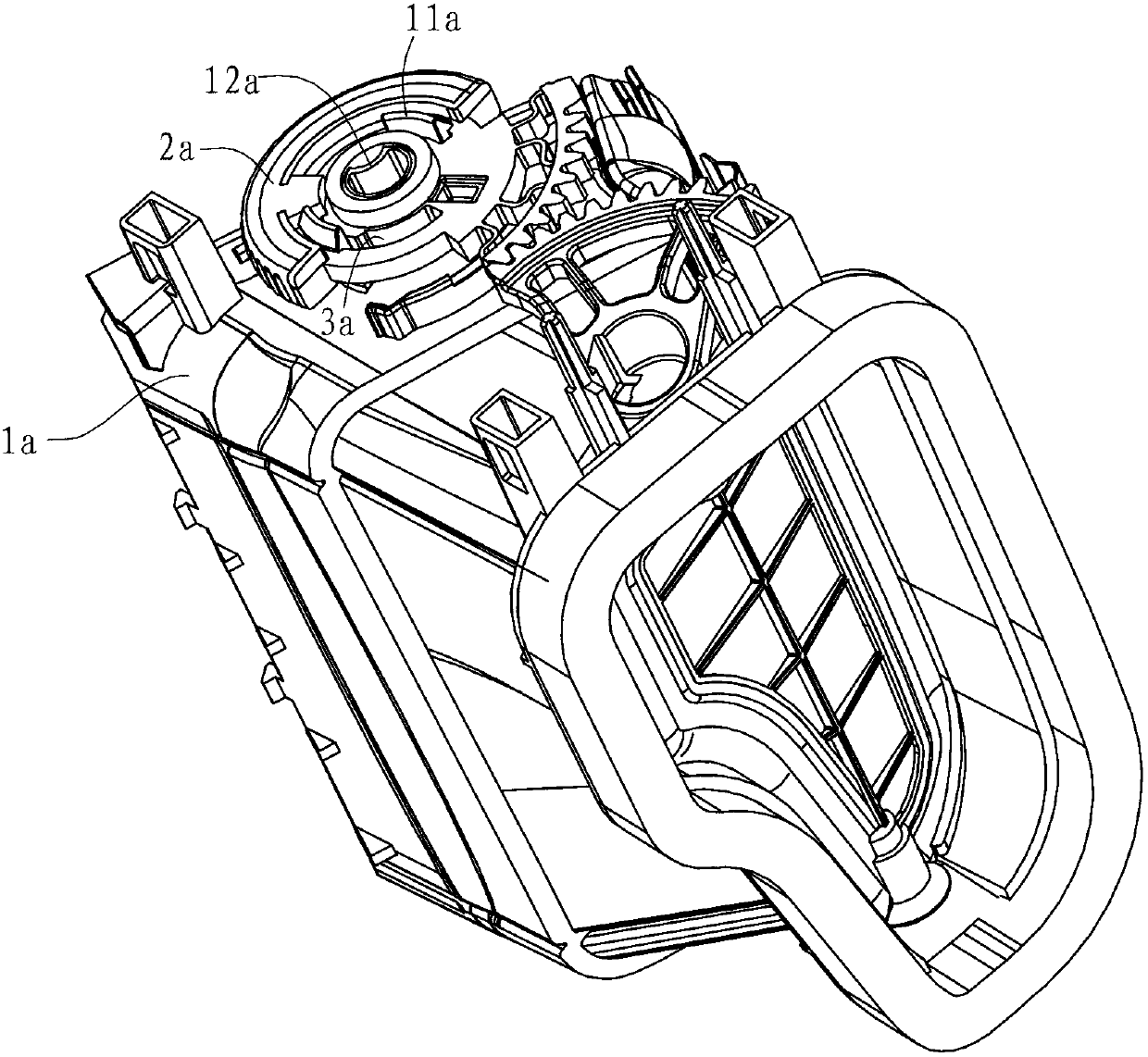

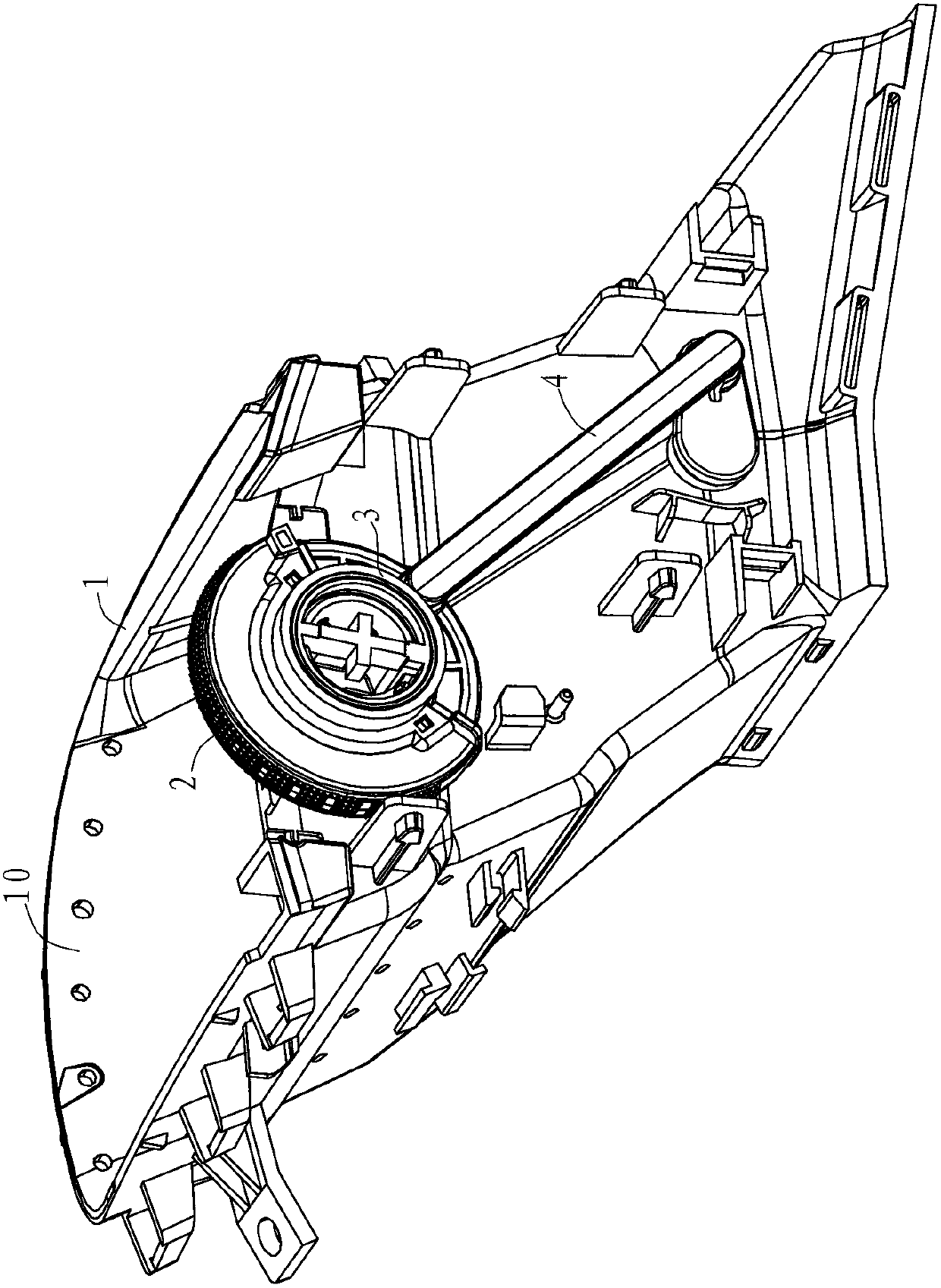

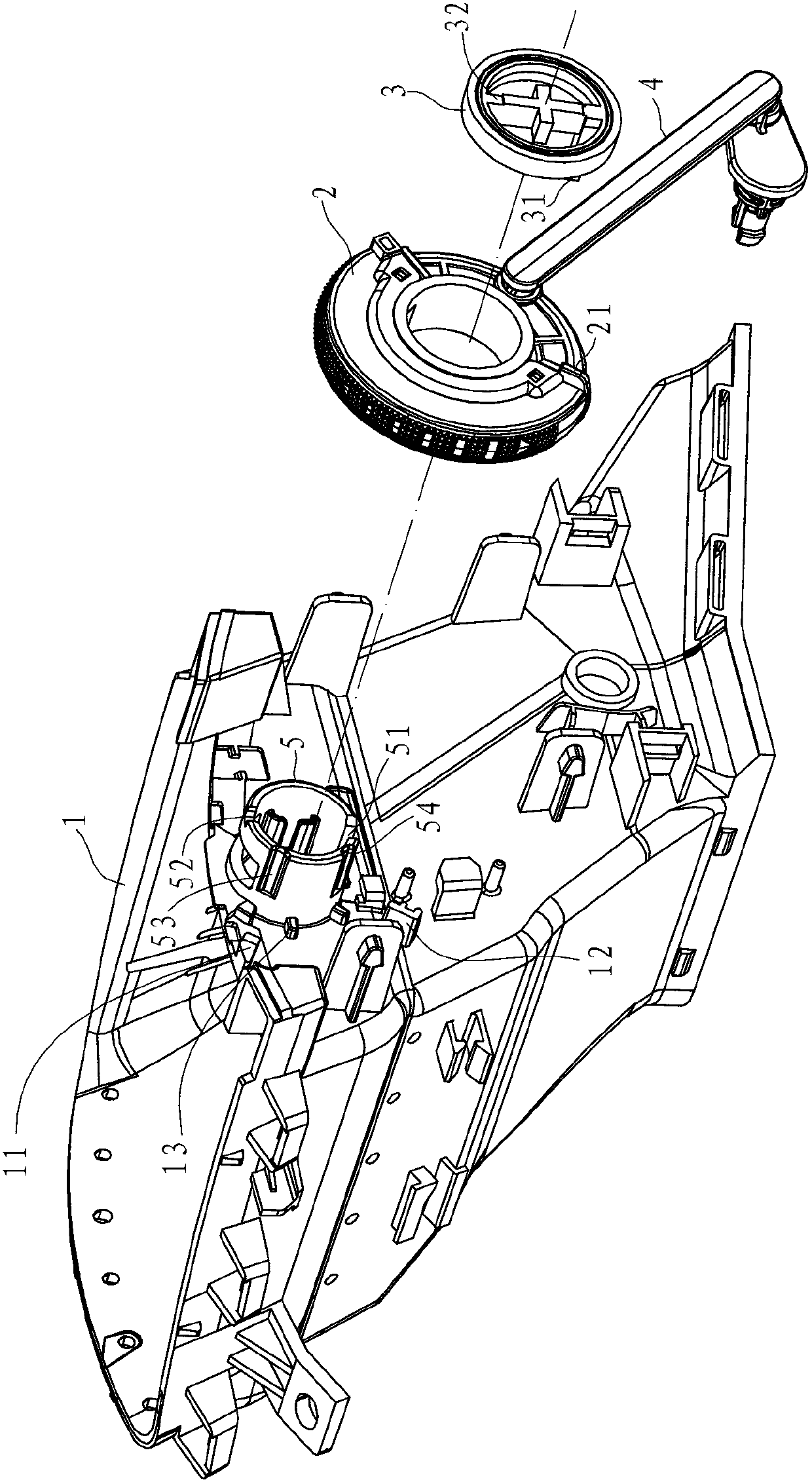

[0027] Example 1, such as figure 2 , image 3 and Figure 6 As shown, the assembly structure of the car air outlet housing and the wheel disc in this embodiment is a single housing structure, including a housing 1, a wheel disc 2 and a retaining ring 3, and the housing 1 has an air outlet 11 and one side protrudes There is a connecting shaft 5 on which the wheel disc 2 is arranged and can rotate around the connecting shaft 5. At the same time, the wheel disc 2 and the windshield blade (not shown in the figure) arranged in the housing 1 are transmitted through the link mechanism 4. connect.

[0028] The retaining ring 3 is sleeved on the connecting shaft and located on the outer surface of the wheel 2 , and the retaining ring 3 axially positions the wheel 2 on the connecting shaft 5 . combine Figure 5 As shown, the inner side of the retaining ring 3 is formed with a first inserting block 31 extending axially outwards. At the same time, the inner side of the retaining ring...

Embodiment 2

[0031] Embodiment 2, such as 7~ Figure 10 As shown, the automobile air conditioner air outlet housing and the wheel disc assembly structure in this embodiment is a double shell structure, including the left housing 1b, the right housing 1c, the left wheel disc 2b, the right wheel disc 2c and the retaining ring 3, the left The casing 1b and the right casing 1c are assembled into one body, the left casing 1b and the right casing 1c have air outlets respectively, the left connecting shaft 5b protrudes from the side of the left casing 1b close to the right casing 1c, and the left wheel disc 2b is provided with On the left connecting shaft 5b and can rotate around the left connecting shaft 5b, the right connecting shaft 5c protrudes from the side of the right casing 1c close to the left casing 1b, and the right wheel disc 2c is arranged on the right connecting shaft 5c and can Rotate around the right connecting shaft 5c, and the left connecting shaft 5b and the right connecting sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com