Device for recovering liquid gas gasification cold

A liquid gas and cooling technology, applied in climate change adaptation, machines using waste heat, and machine operation modes, etc., can solve problems such as high operating costs, loss of cooling capacity, waste, etc., to achieve high safety factor and ensure continuity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

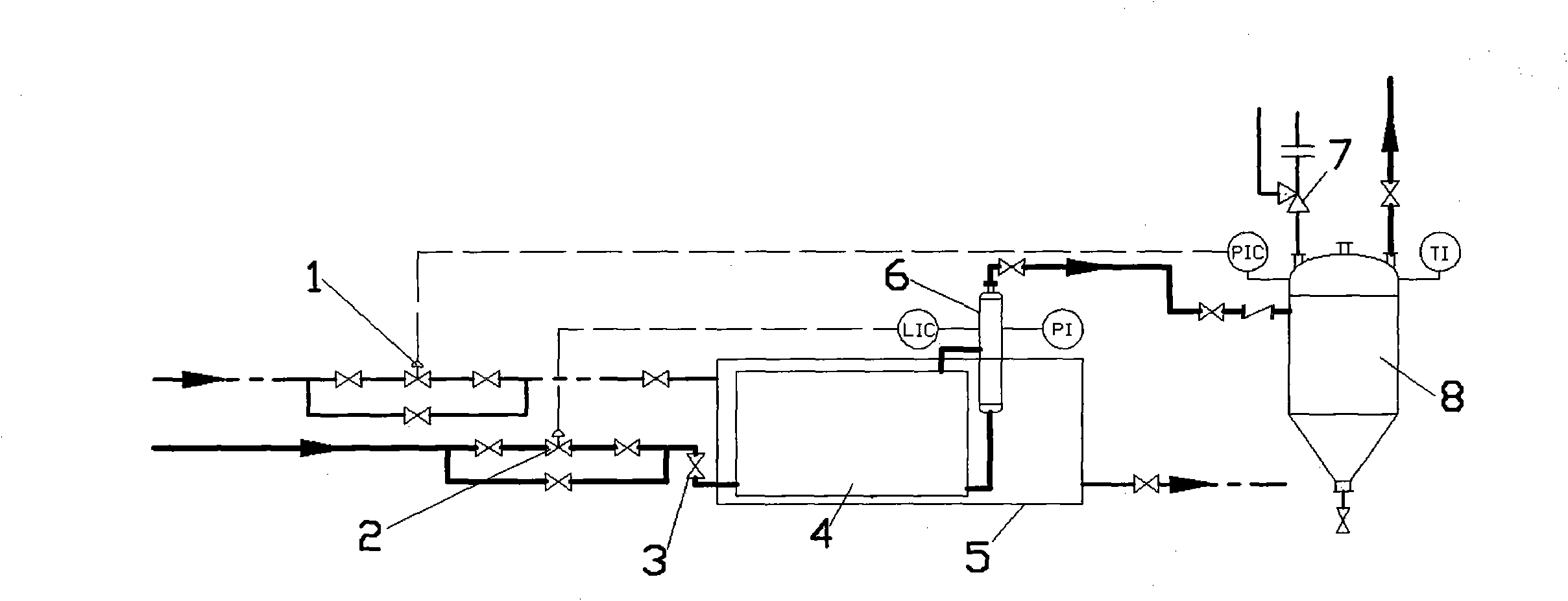

Method used

Image

Examples

Embodiment Construction

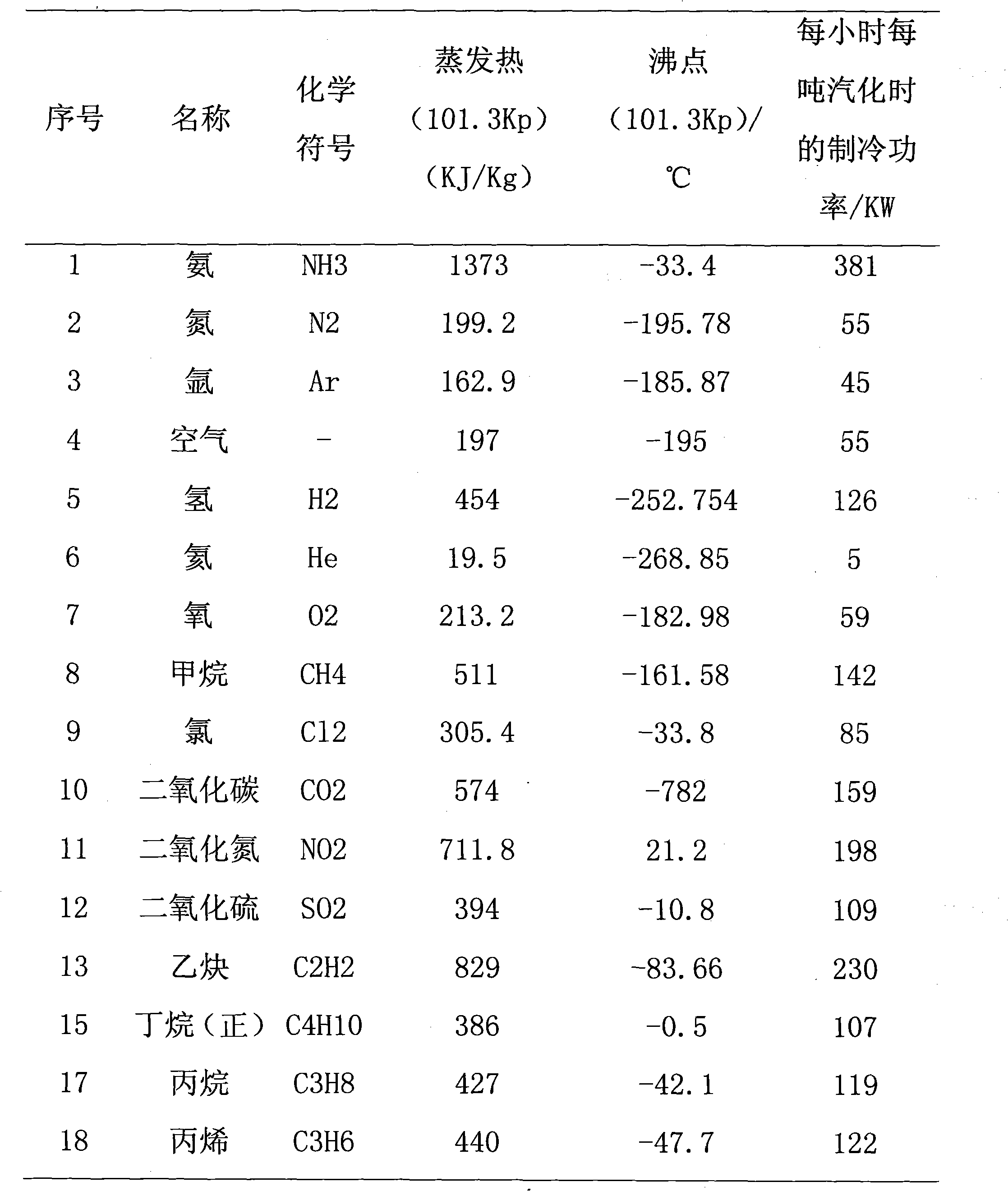

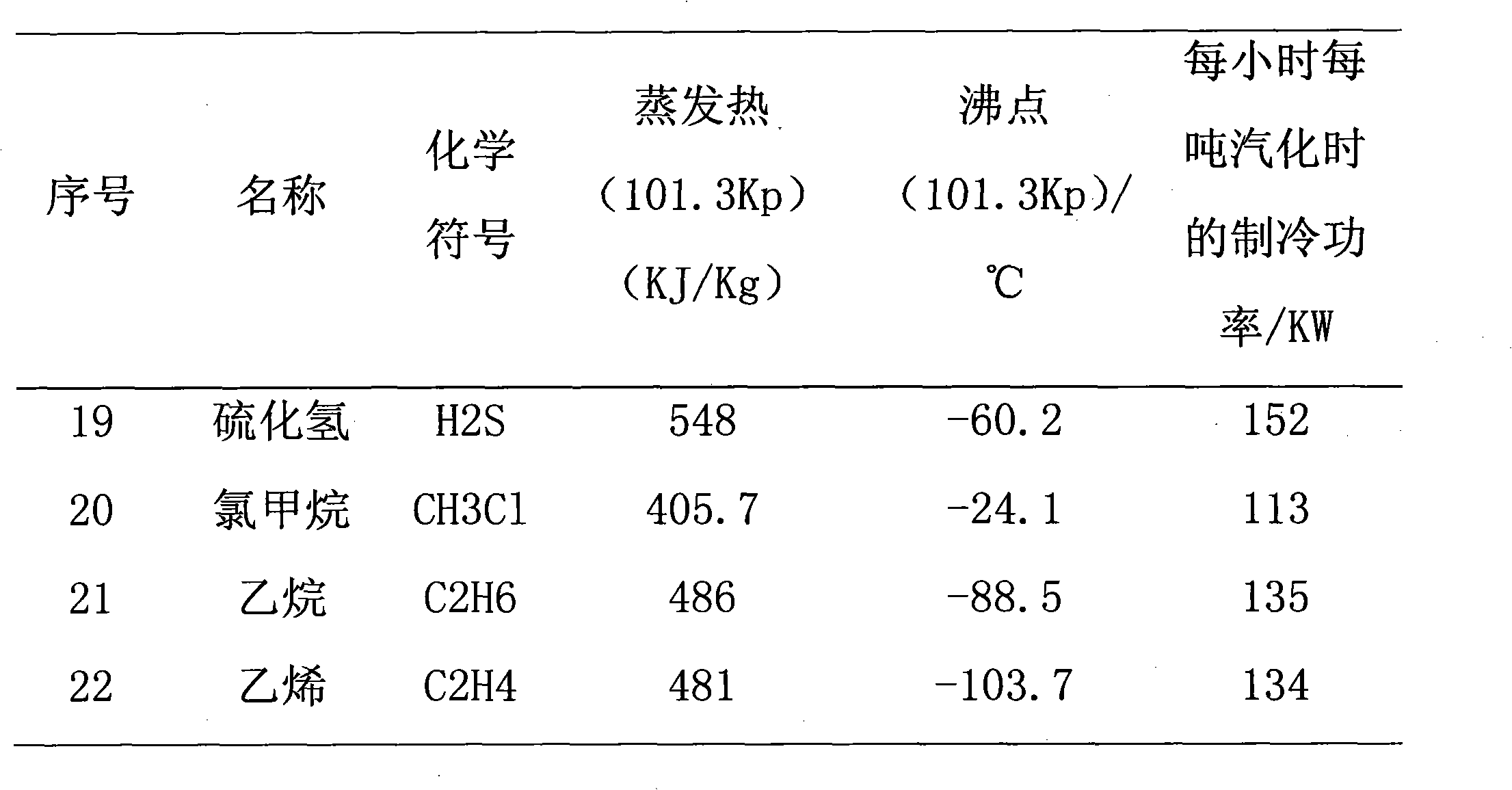

[0019] The method is applied to the vaporization of chlorine gas in the phosphorus trichloride production process. The vaporization amount of chlorine gas in the process is 6.46t / h, the vaporization pressure is controlled at 0.2Mp, the vaporization temperature is -6℃~-7℃, and frozen brine is used as the refrigerant, and its refrigeration power can reach 490KW. Through vaporization, low-temperature brine at -5°C to 0°C can be prepared for cooling other links in the production process. Compared with the previous liquid chlorine vaporization, this method not only does not require warm water or steam, but also effectively utilizes the cooling capacity of vaporization. Kill two birds with one stone, and the energy saving effect is remarkable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com