Gyro sensor calibration device and calibration method

A calibration method and a calibration device technology, which are applied to instruments, measuring devices, etc., can solve problems such as inability to calibrate in batches, and achieve the effects of efficiency improvement, cost saving, and reasonable temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

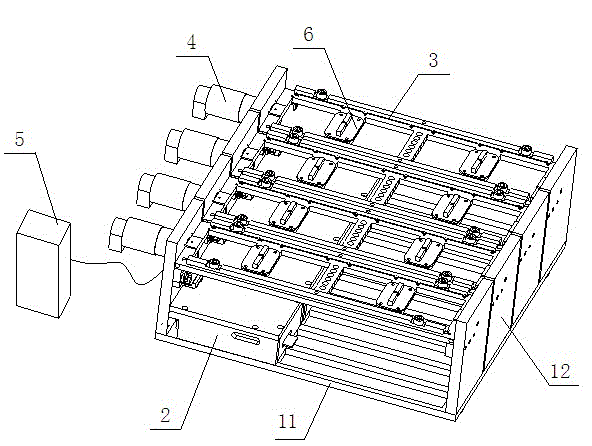

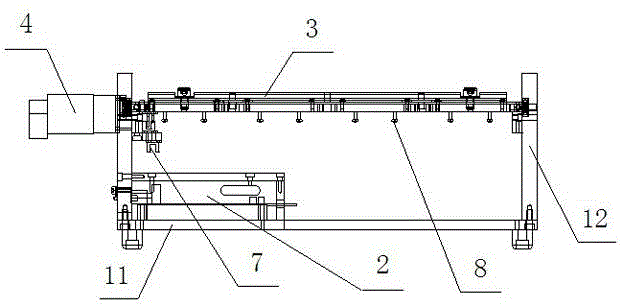

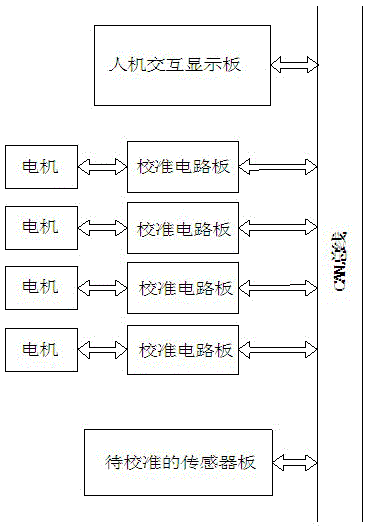

[0055] Such as figure 1 and figure 2 As shown, a gyro sensor calibration device includes a CAN bus, a fixed table, a calibration circuit board 2, a rotating frame 3 capable of fixing multiple sensor boards, a motor 4 that drives the rotating frame 3 to rotate, and a human-computer interaction display board 5. The fixed table is composed of a base plate 11 and side plates 12 symmetrically arranged on both sides of the base plate 11, the calibration circuit board 2 is placed on the base plate 11, and the two ends of the rotating shaft of the rotating frame 3 are respectively installed on the The side plates 12 on both sides of the bottom plate 11. A sensor socket device 6 for powering on and communicating with the sensor board is provided on the rotating frame 3 , and the sensor socket device 6 is connected to the CAN bus. The motor 4 is installed on the side of the side plate 12 and connected with the rotating shaft of the rotating frame 3 . The side plate 12 is also provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com