Multi-layer shearing direct shear device

A shearing instrument, a direct technology, applied in the direction of applying stable shearing force to test the strength of materials, etc., can solve the problems of high cost of purchasing instruments, high manpower, time and financial resources, and large size disparity of bulk coarse grain materials. Achieve the effect of improving reliability and accuracy and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

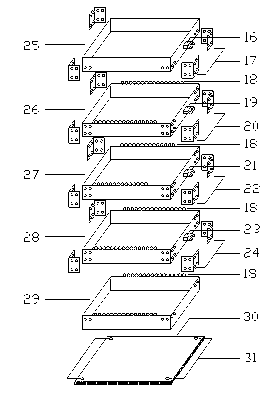

[0037] Embodiment 1: the direct shearer device of the multi-layer shearing of the present embodiment, comprises outer frame device 54, shearing box device 55, horizontal loading device 58 and support device 56, shearing box device 55 and horizontal loading device 58 are distributed inside the outer frame device 54, and the supporting device 56 is positioned at the side of the shear box device 55; the position corresponding to the shear box device 55 on the top of the outer frame device 54 is provided with a vertical loading device, and the position corresponding to the horizontal loading device 58 is provided with a Lifting device 57; The multi-layer steel frame that supports horizontal loading device 58 is arranged on the outer frame device 54, and shear box device 55 has multi-layer shear box, and supporting device 56 has multi-layer support block, multi-layer steel frame, multi-layer The layer shear box is flush with each layer corresponding to the multi-layer support block....

Embodiment 2

[0038] Embodiment 2: the direct shearer device of the multi-layer shearing of the present embodiment, the outer frame device 54, the shear box device 55, the horizontal loading device 58 and the supporting device 56, the shear box device 55 and the horizontal loading device 58 Distributed inside the outer frame device 54, the supporting device 56 is located on the side of the shear box device 55; the top of the outer frame device 54 is provided with a vertical loading device at the position corresponding to the shear box device 55, and a hoisting device at the position corresponding to the horizontal loading device 58 Device 57; the multi-layer steel frame supporting horizontal loading device 58 is arranged on the outer frame device 54, and the shear box device 55 has five layers of shear boxes, and the supporting device 56 has five layers of supporting blocks, five layers of steel frame, five layers of Each layer corresponding to the shear box and the five layers of supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com