Device and method for testing hot-shrinkage rate of chemical fiber filaments

A testing device and filament heating technology, applied in the direction of thermal expansion coefficient of materials, etc., can solve the problems of difficult calibration and calibration of instrument force value, bulky instrument, inconvenient operation and use, etc. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

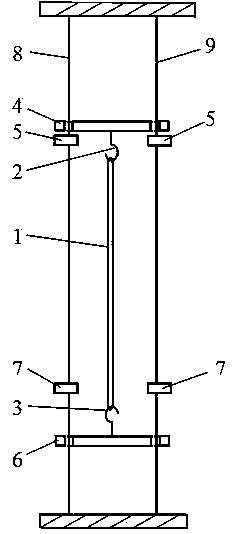

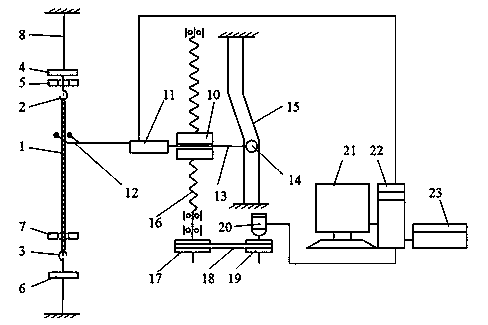

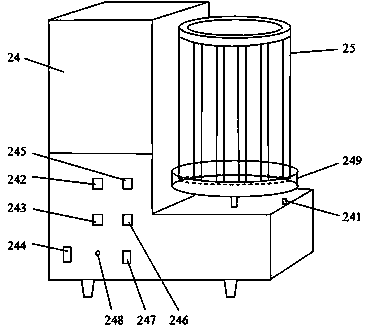

[0030] See Figure 1-3 The invention discloses a testing device for the thermal shrinkage of chemical fiber filaments. Such as figure 1 As shown, the main innovation of the present invention is: it includes a dual limiter structure and a load cell 11; the dual limiter structure includes upper hook 2, lower hook 3, upper hook plate 4, upper limiter 5, and lower hook. Hook plate 6, lower limiter 7, metal guide wires 8, 9; the upper hook 2 is connected below the upper hook plate 4, the upper hook plate 4 is located above the upper limiter 5 and is restricted to only above the upper limiter 5 Sliding along the metal guide wire; the lower hook 3 is connected to the upper hook plate 6, the lower hook plate 6 is located under the lower limiter 7 and is restricted to only slide along the metal guide wire under the lower limiter 7; installed with the The fork 12 of the toggle mechanism of the load cell 11 can lift the upper hook plate 4 to move upward so as to load the twisted wire sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| perimeter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com