Automatic intrinsic safety meter checking system

A technology of automatic calibration and intrinsic safety meter, which is applied in the direction of material inspection products, measuring devices, instruments, etc., can solve the problems of heavy calibration workload, lack of equipment, and long calibration time, so as to reduce calibration time, health protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

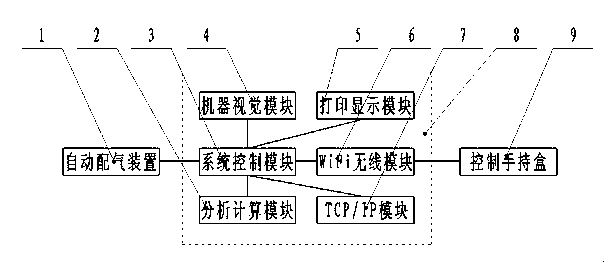

[0013] As shown in the figure, an intrinsic safety meter automatic calibration system includes a detection box and a control hand-held box. The detection box is equipped with a system control module and a machine vision module connected to it, an analysis and calculation module, a printing display module, a TCP / The IP module and the data communication module also include an automatic gas distribution device. The system control module of the detection box is connected to the automatic gas distribution device. The data information in the detection box communicates with the control hand-held box through the WiFi wireless module.

[0014] When the system is applied, the calibration personnel can first place the intrinsically safe instrument to be calibrated in the detection box 8 and seal the detection box 8 . This moment by controlling hand-held box 9 to issue the instruction of verification. The command is transmitted by the control handheld box 9 to the computer of the system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com