Lateral-bottom-fed coil loading machine with hydraulic rocker-slider mechanism

A rocker slider and hydraulic technology, applied in the direction of electrical components, circuits, cables/conductors, etc., can solve the problems of inability to synchronize displacement, increase difficulty, change, etc., and achieve the effect of improving work efficiency and simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

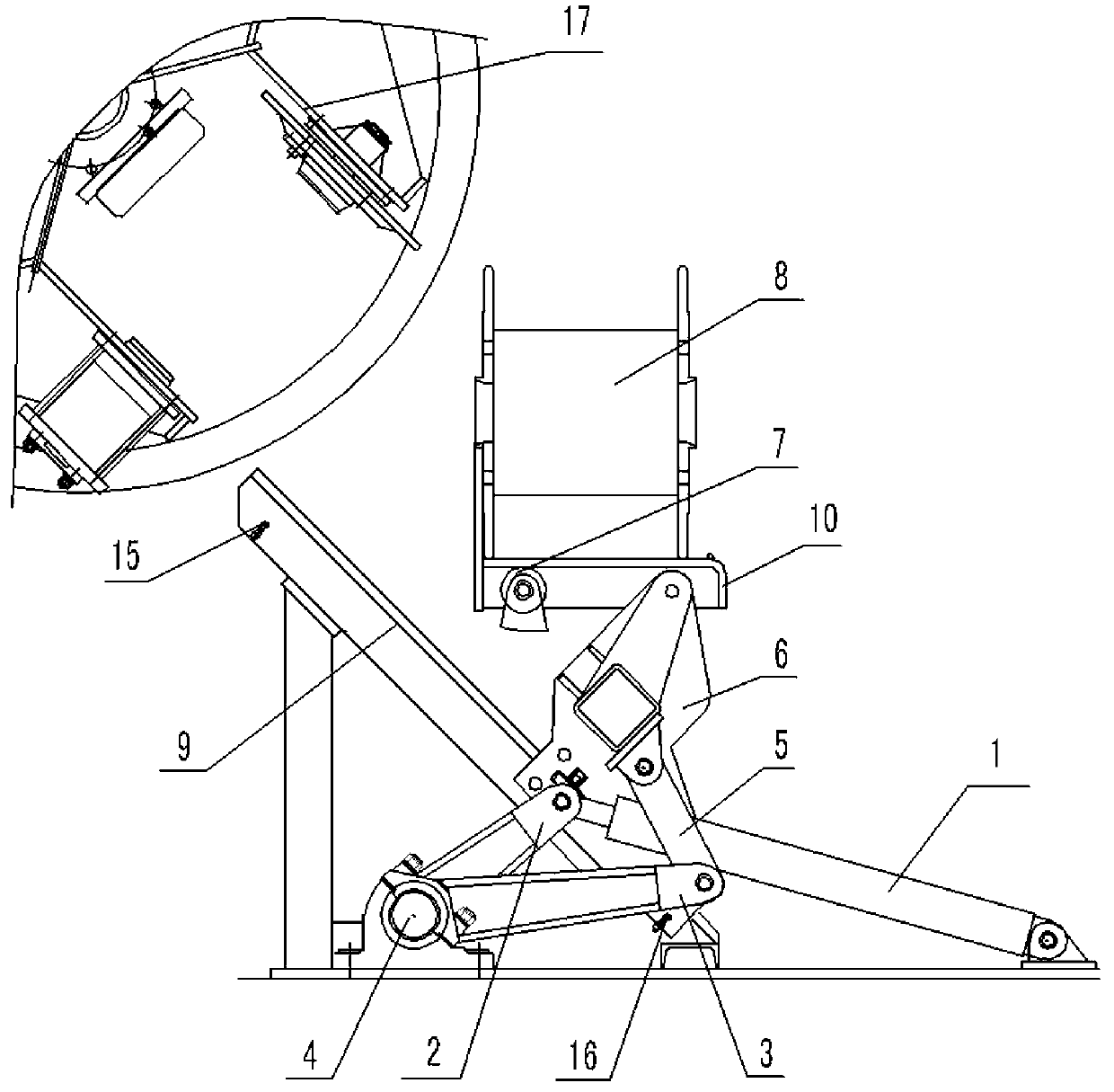

[0026] In this embodiment, the structure of the upper plate machine under the side of the hydraulic rocker slider is set as follows:

[0027] see figure 1 , the hydraulic cylinder 1 as the driving mechanism is hinged with the transmission rocker 2 with its piston rod end, and the other end of the transmission rocker 2 is fixedly sleeved on the main shaft 4 for driving the rotation of the main shaft 4.

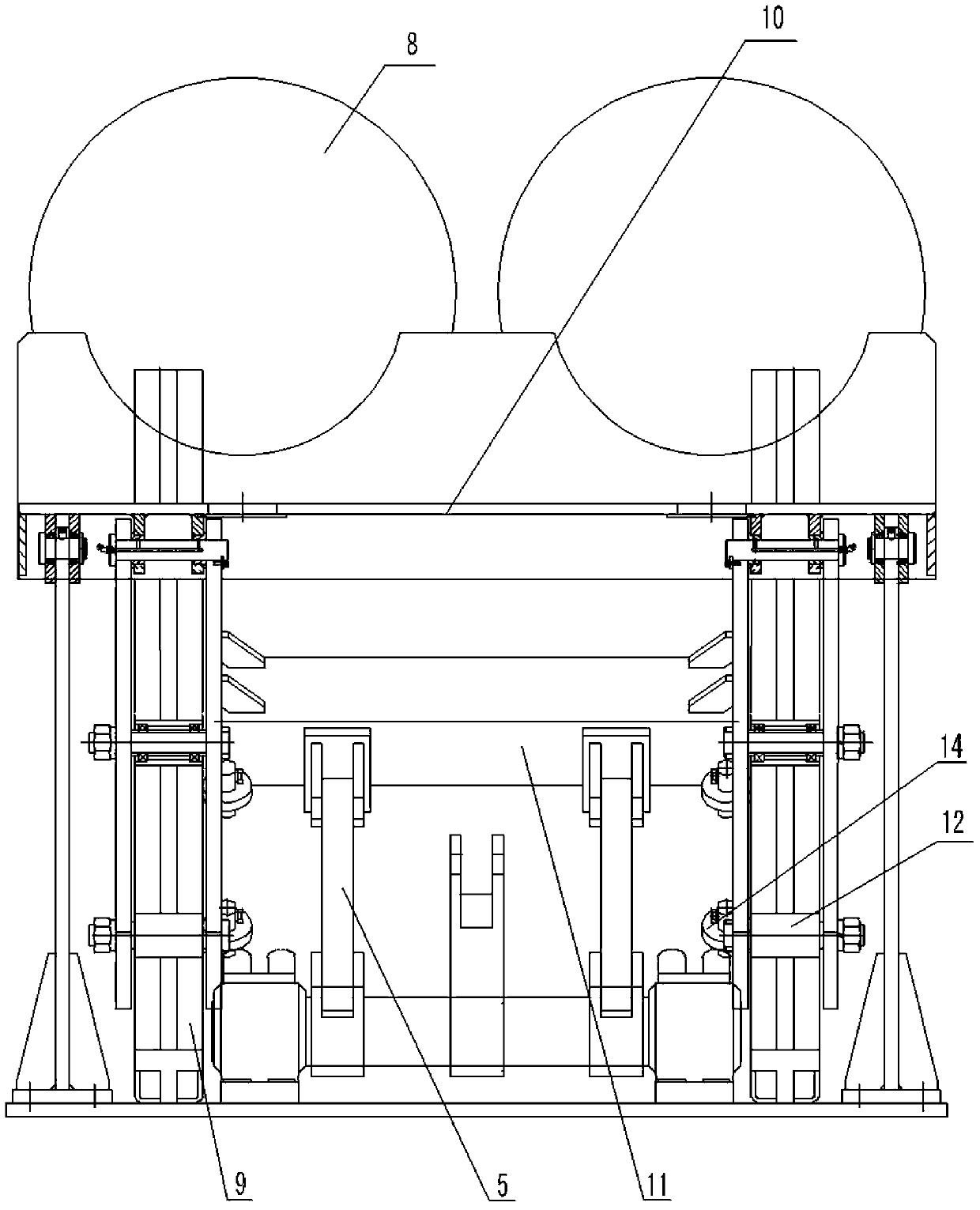

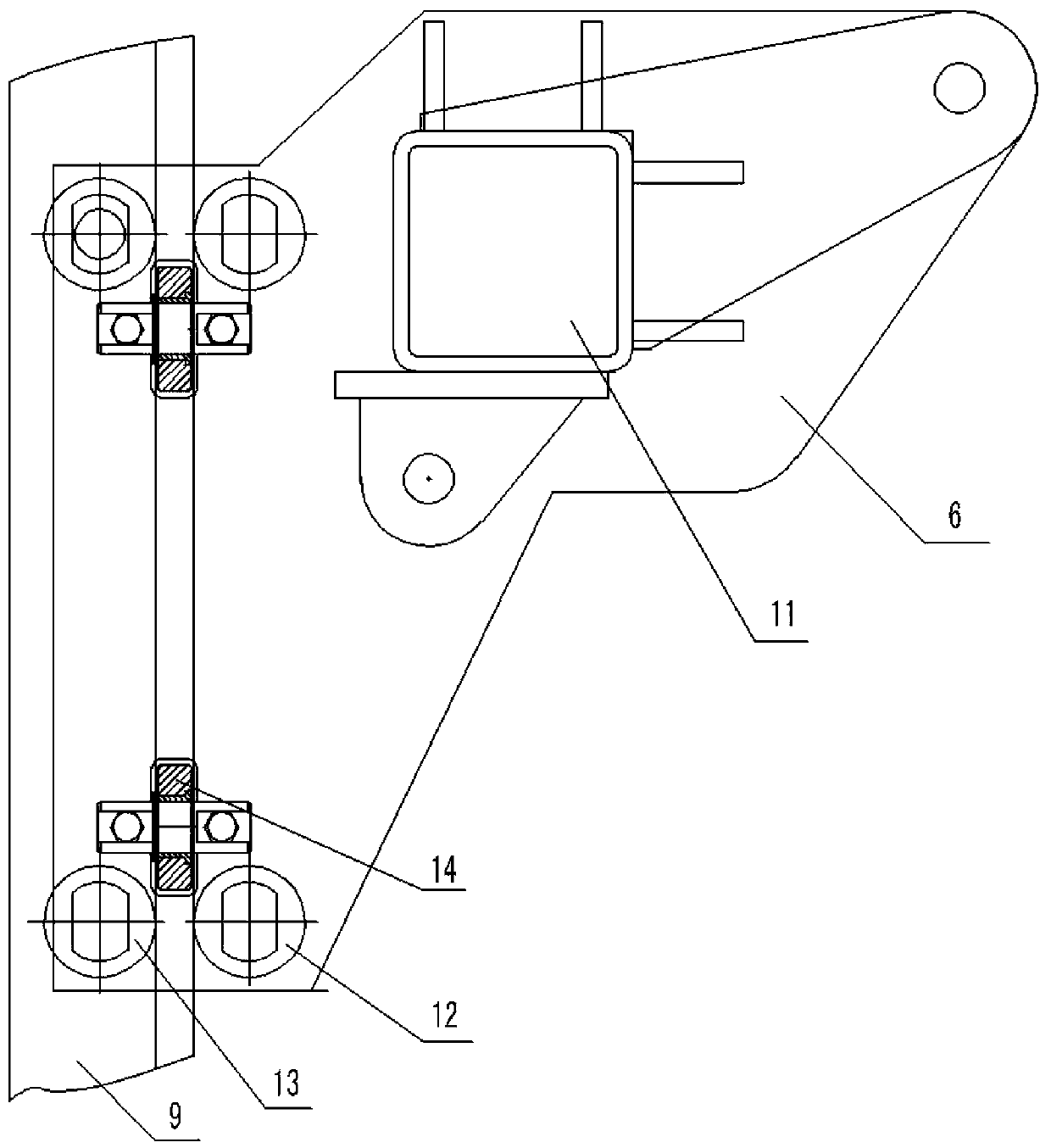

[0028] Such as figure 1 and figure 2 As shown, the wire reel frame 10 is arranged on the top of the main shaft 4, and the wire reel frame 10 in the horizontal state is positioned at the bottom on the inner side and is supported by the turning wheel 7 in a fixed position, and the turning wheel 7 is supported by the turning wheel frame on the machine. On the frame; the wire reel frame 10 is located at the bottom on the outside and is supported by the mobile plate 6, and the mobile plate 6 is hinged to the bottom of the wire reel frame 10 with its top;

[0029] A lifting mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com