Capacitive voltage division type self-triggering linear transformer driver

A capacitive voltage dividing and self-triggering technology, applied in the field of pulse power, to achieve the effect of reducing requirements, simple structure and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

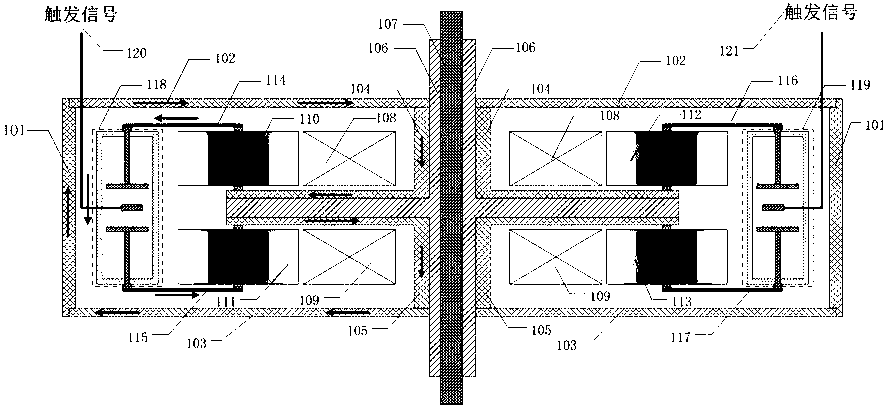

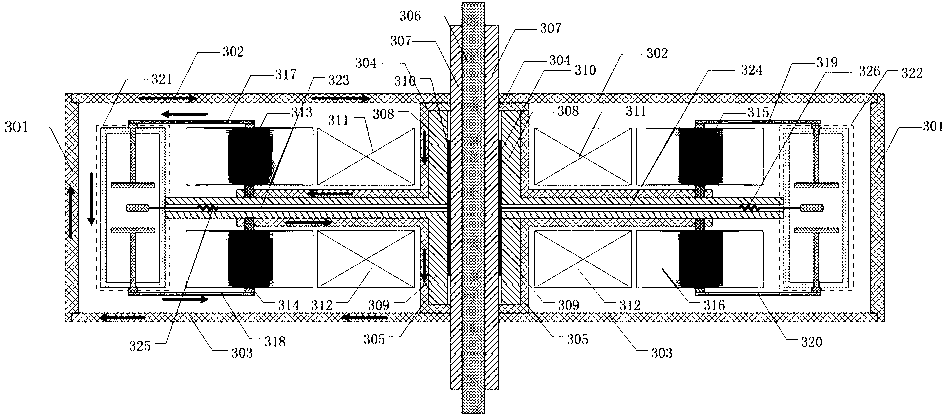

[0025] image 3 The working principle of the self-triggering LTD induction chamber shown is the same as that of the ordinary LTD induction chamber: first charge the capacitors 313, 314, 315, 316 positively and negatively, then the gas switches 321, 322 are turned on, and the current is in the direction indicated by the arrow in the figure flow. The capacitor and the magnetic cores 311 and 312 form a primary circuit for discharging, and couple the energy stored in the capacitor to the secondary metal bus bar 306 . The difference is that the common LTD sensing cavity conducts the gas switch through an external trigger, while the self-triggering LTD sensing cavity obtains a trigger signal from the trigger cylinder 310 through the principle of capacitive voltage division.

[0026]The central busbar 306, the metal trigger cylinder 301, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com