Solderable fluid channel for a heat exchanger of aluminium

A technology of fluid channels and heat exchangers, applied in the direction of heat exchanger fixation, heat exchange equipment, indirect heat exchangers, etc., can solve the problem of damaging the cooling medium of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

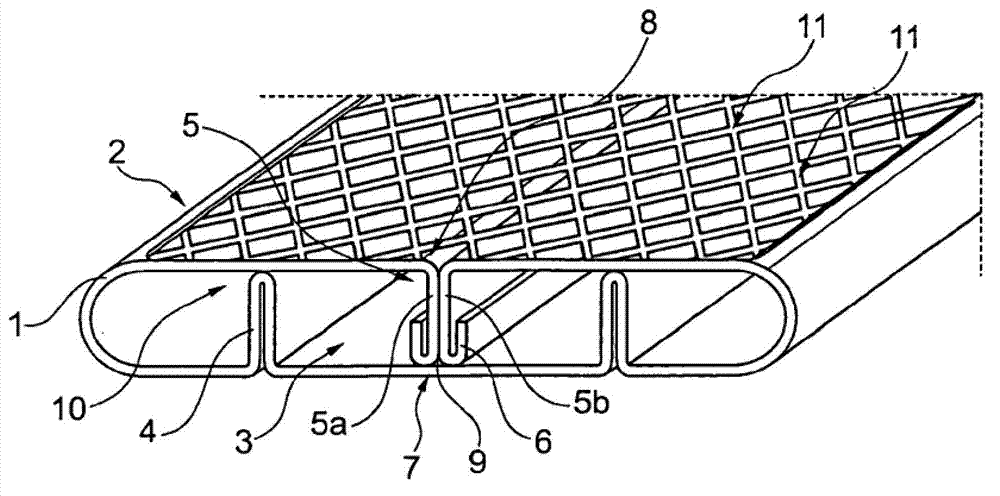

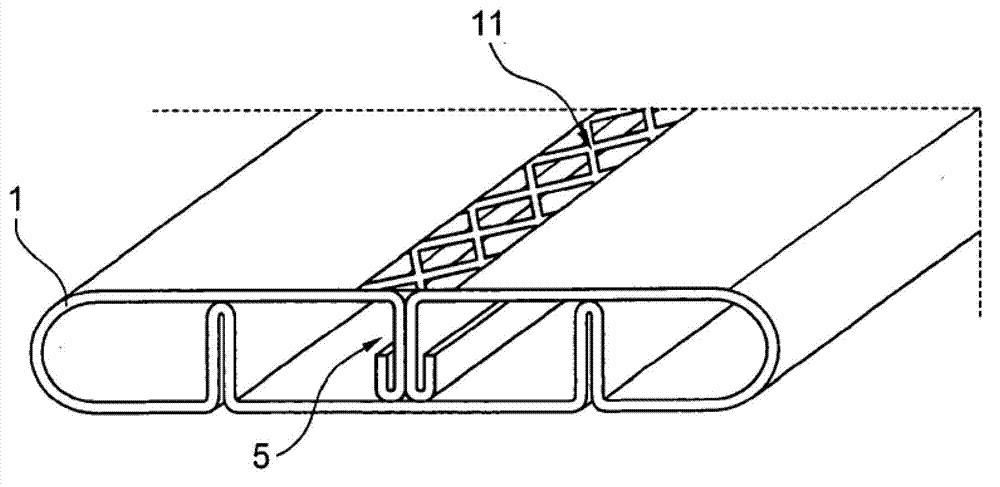

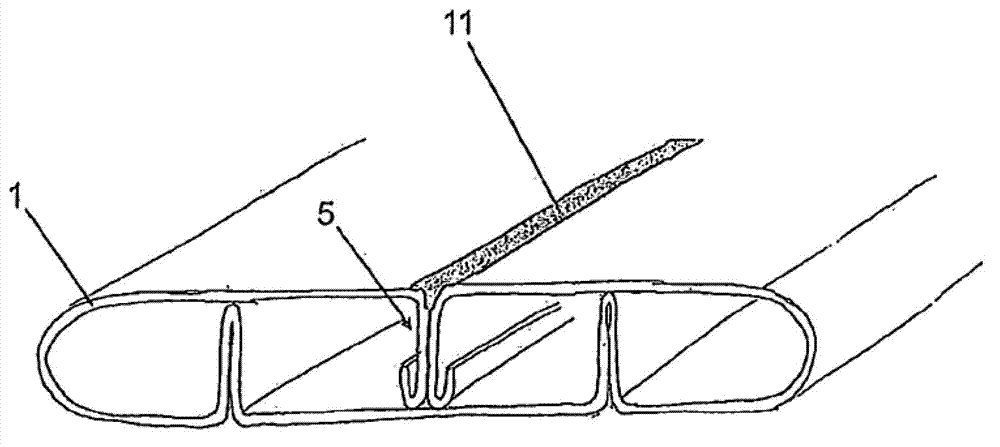

[0037] The fluid channel shown in FIG. 1 is formed as a flat tube formed from a single sheet metal 1 . The metal sheet 1 consists of an aluminum alloy, which here has a magnesium content. In this case (but not necessarily), at least on the outer surface 2 the core region of the metal sheet is coated with a flux coating. For this and all other embodiments, the following alloys are preferred (all The expressions are weight-%):

[0038] Core area / basic material of sheet metal:

[0039]

[0040] Solder cladding:

[0041]

[0042]

[0043] The flat tube is designed here as a multi-chamber flat tube with two folded webs 4 and connection grooves 5 for closing the tube in the longitudinal direction.

[0044] The connection groove 5 is arranged here on the broad side of the flat tube. It contains a first socket section 5 a and a second socket section 5 b , which are each formed by bending the opposite edge regions of the sheet metal 1 by 90°. The flanges 6 are each conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com