Desulfurization and denitrification dust collector

A dust collector and denitrification technology, which is applied to chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of poor comprehensive performance of desulfurization, denitrification and dust removal, high cost, complicated processing, etc., and achieve ideal comprehensive performance. Low cost, improve the effect of contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

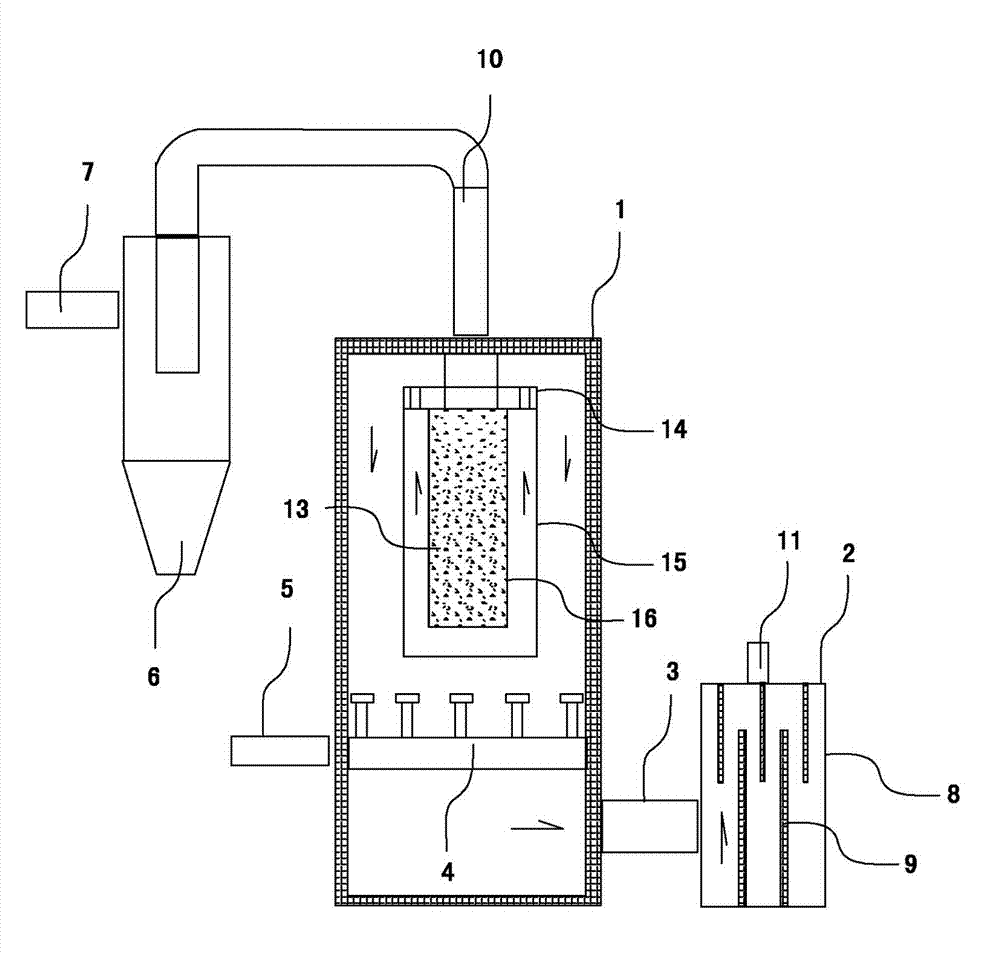

[0010] As shown in the figure, the desulfurization and denitrification dust collector includes a desulfurization and denitrification reaction tank 1 and a vapor-liquid phase separation tank 2; the desulfurization and denitrification reaction tank 1 communicates with the vapor-liquid phase separation tank 2 through a delivery pipeline 3; The desulfurization and denitrification reaction tank 1 is fixed with a filter liner 14; the filter liner 14 includes an outer tank body 15 and an inner liner core 16 set therein; the outer wall of the inner liner core 16 is provided with a through hole; the inner liner The filter material 13 is built into the core 16; the cavity formed by the outer wall of the inner tank core 16 and the inner wall of the outer tank body 15 communicates with the desulfurization and denitrification reaction tank 1; The flue gas inlet 10 communicates; the bottom of the desulfurization and denitrification reaction tank 1 is fixedly provided with a spray mechanism 4...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap