Flanging die

A flanging mold and template technology, applied in the field of flanging molds, can solve the problems of poor flanging effect and high manufacturing cost, and achieve the effects of high processing efficiency, reasonable structural design, and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

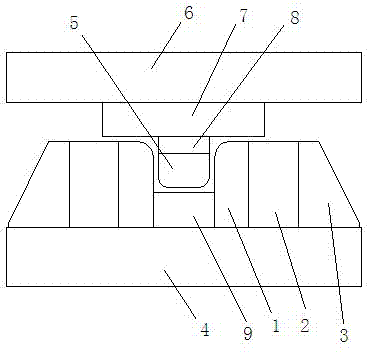

[0013] see figure 1 , flanging mold, has upper mold 6 and lower mold 4 that are arranged up and down, upper mold 6 bottom is provided with upper formwork 7, the bottom of upper formwork 7 is provided with backing plate 8, and the bottom of backing plate 8 is provided with embossing mod 5.

[0014] The upper part of the lower mold 4 is provided with a ring-shaped first lower template 3, the inner side of the first lower template 3 is provided with a ring-shaped second lower template 2, and the inner side of the second lower template 2 is provided with a ring-shaped third lower template 1 , The inner side of the third lower template 1 is provided with a die 9 .

[0015] When the upper mold 6 and the lower mold 4 are close, the male mold 5 is inserted into the female mold 9 , and the two sides of the male mold 5 are against the inner side of the third lower template 1 .

[0016] The material of upper die 6 and lower die 4 is A3 steel, and the materials of upper die 7, backing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com