Stabilizer bar forming accurate device

A stabilizer bar, precise technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of poor consistency, poor precision and consistency of stabilizer bar finished products, and achieve the effect of ensuring accuracy and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

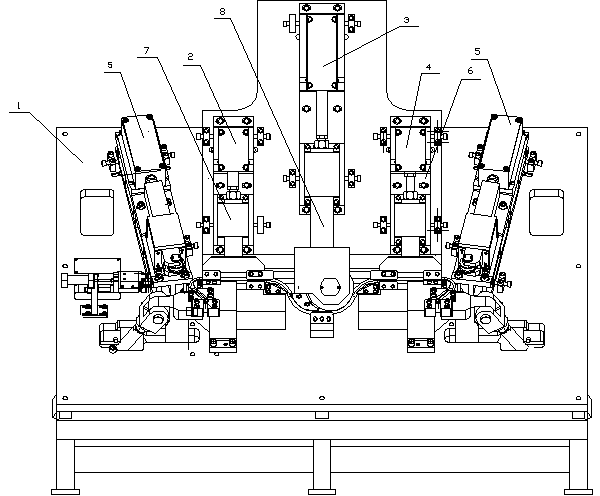

[0010] A stabilizer rod forming precision device, the device is arranged on the bottom plate 1 of the forming machine, the device includes four hydraulic cylinders, a module action precise guide rail mechanism, the hydraulic cylinder one 2, hydraulic cylinder two 3, hydraulic cylinder three 4 1, hydraulic cylinder 4, and 5 respectively face the end, slope and middle of the stabilizer bar, and the hydraulic cylinder 1 2, hydraulic cylinder 2 3, hydraulic cylinder 3 4, and hydraulic cylinder 4 5 are connected to a precise guide rail mechanism. The precise guide rail mechanism of the described module is composed of a square guide rail 6, a square guide block 7, and a lubrication system. The square guide block 7 is controlled by the square guide rail 6 to move forward and backward. 1. Hydraulic oil cylinder 4 5 is connected with a piston push rod, and promotes the square guide block 7 at the front end of the precise guide rail mechanism of the module action.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com