Mutual-induction decoupling control method of multi-station linear cutting wire electrodes

A technology of decoupling control and electrode wire, which is applied in the field of mutual inductance decoupling control of multi-station wire cutting electrode wire, can solve the problems of mutual interference between stations, affecting processing consistency and precision, and no research method has been formed, so as to achieve the guarantee Consistency and precision, effect of eliminating influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

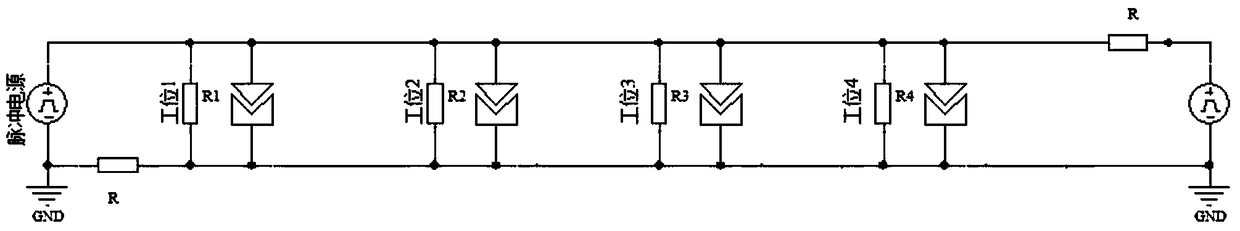

[0022] Please refer to figure 1 , figure 1 It is a schematic diagram of the processing state of the multi-station wire electric discharge wire electrode in the prior art. Since the wire electrode passing signal and the pulse power signal are different between different stations, it is necessary to detect the interference waveform of the electrode wire between adjacent stations. Signals are collected, processed, and analyzed. Since the electrode wire moves back and forth during work, the electrode wire cannot be welded into the circuit, and it is extremely difficult to measure the electrical signals of each station. The multi-station wire cutting machine tool is simplified into four variable resistors, and between adjacent stations decoupling control.

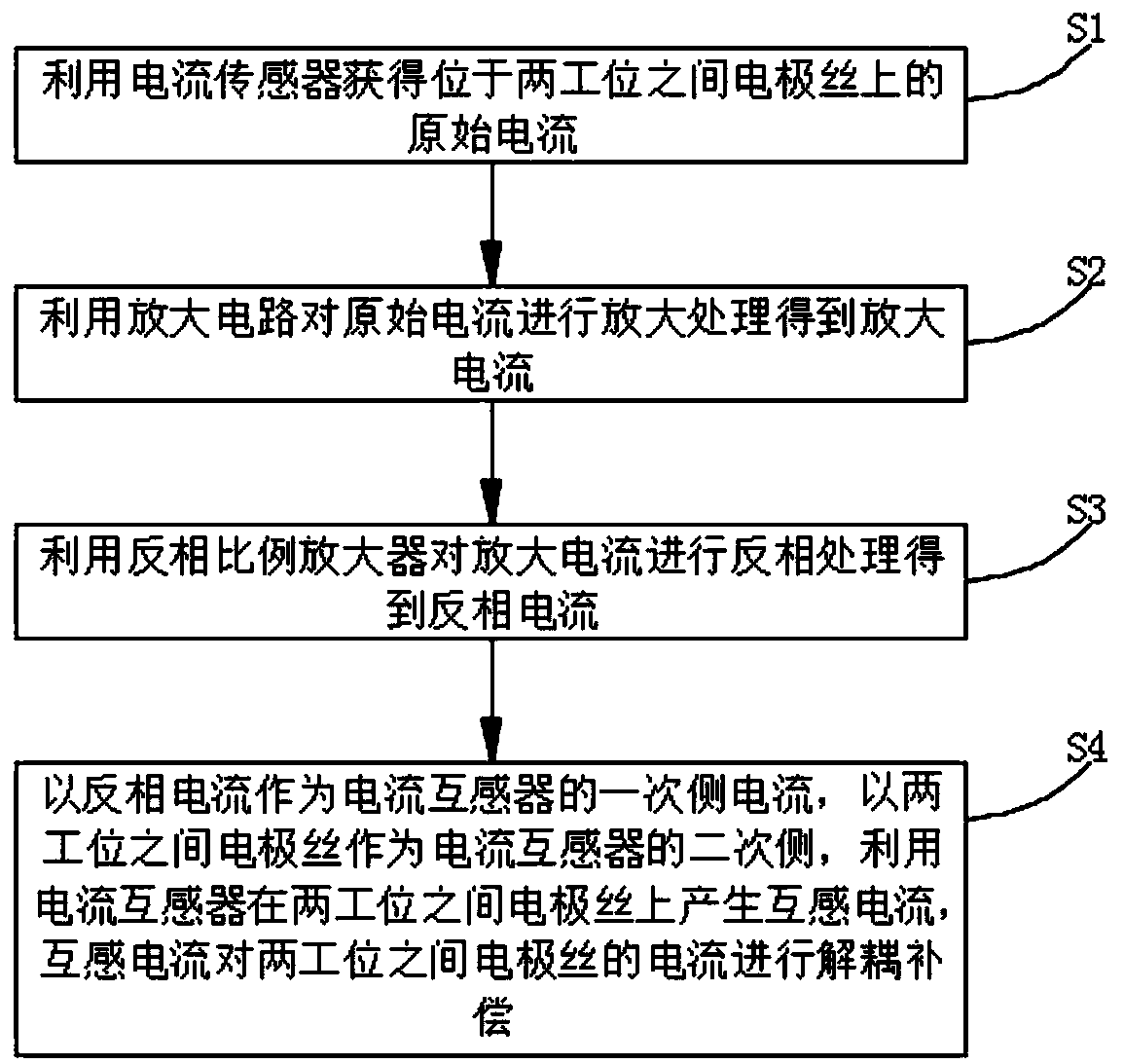

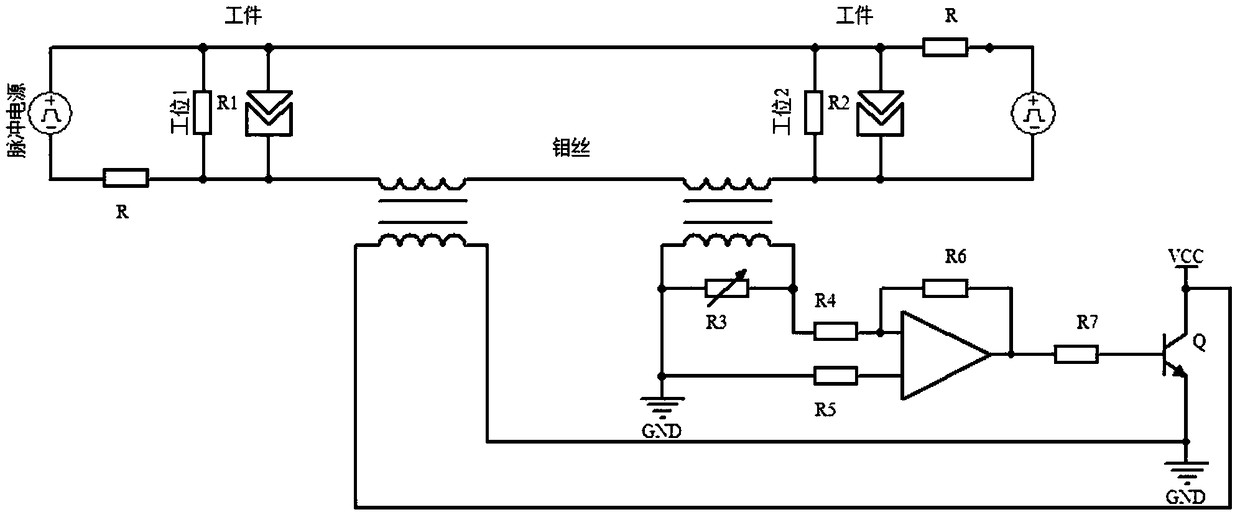

[0023] Please refer to figure 2 and image 3 , a mutual inductance decoupling control method for multi-station wire cutting electrode wire, comprising the following steps:

[0024] Use the current sensor to obtain the orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com