Multi-station wire electric discharge cutting time-sharing pulse power supply synchronous processing method

An EDM wire and pulse power supply technology, applied in electric processing equipment, metal processing equipment, circuits, etc., can solve the problems of consistency, inability to guarantee discharge energy, low processing efficiency, etc., to avoid the interference of induced current, improve efficiency and Processing quality, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

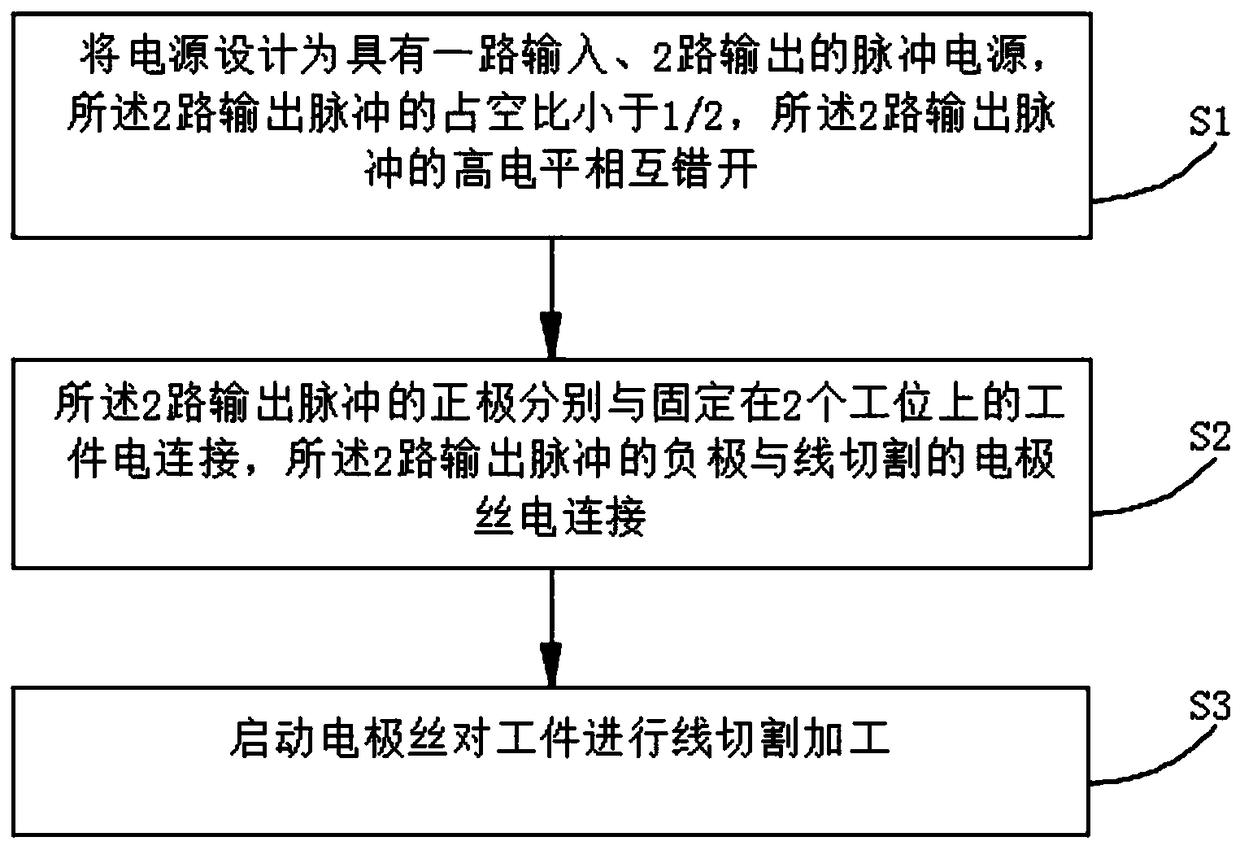

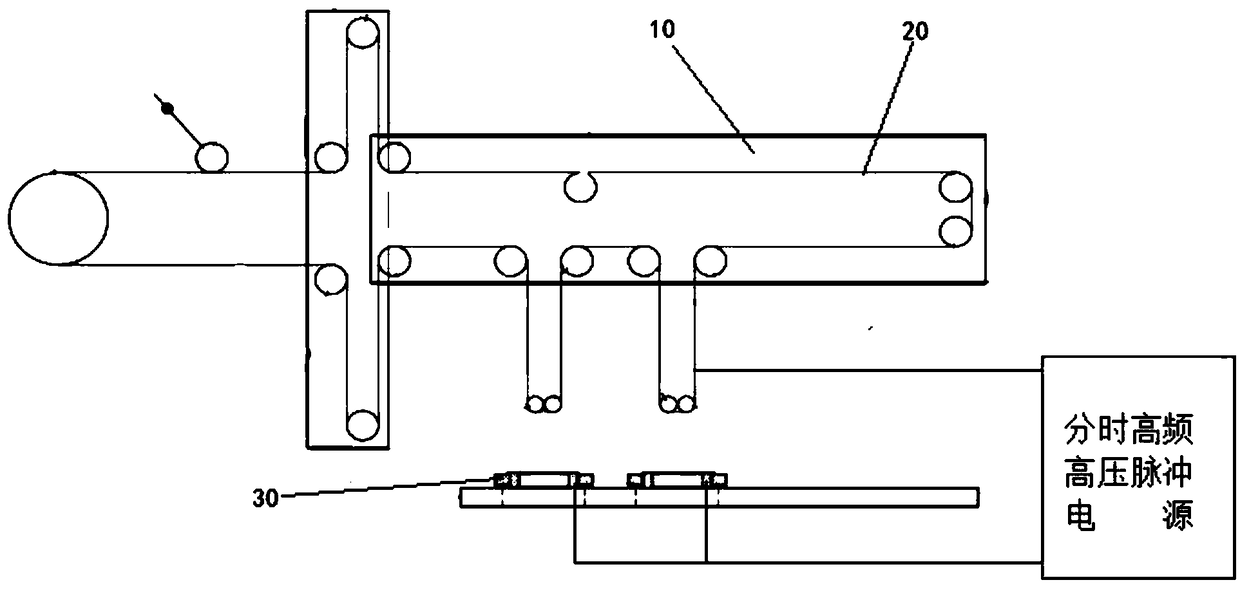

[0021] Please refer to figure 1 and figure 2 , a multi-station wire electric discharge cutting time-sharing pulse power supply synchronous processing method, the number of wire cutting stations of the multi-station wire electric discharge cutting equipment is 2, comprising the following steps:

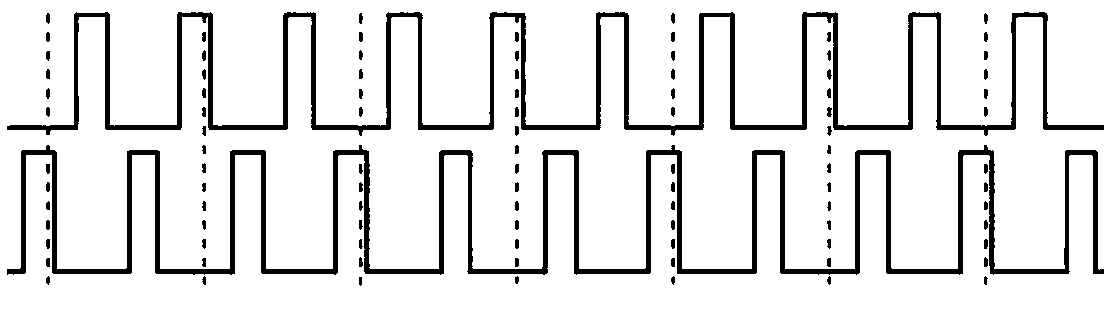

[0022] The power supply is designed as a pulse power supply with one input and two outputs, and the duty cycle of the two output pulses is less than The high levels of the two output pulses are staggered from each other;

[0023] The positive poles of the two output pulses are respectively electrically connected to the workpieces fixed on the two stations, and the negative poles of the two output pulses are electrically connected to the electrode wires of wire cutting;

[0024] Start the wire electrode to perform wire cutting on the workpiece.

[0025] It can be seen from the above that the present invention utilizes time complementarity between power supply pulses to output 2 out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com