Variable-position flat turning device

A variable and rotating shaft technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems that cannot be completed, cannot rotate the workpiece horizontally, etc., and achieve the effect of improving work efficiency, flexible and reliable action, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

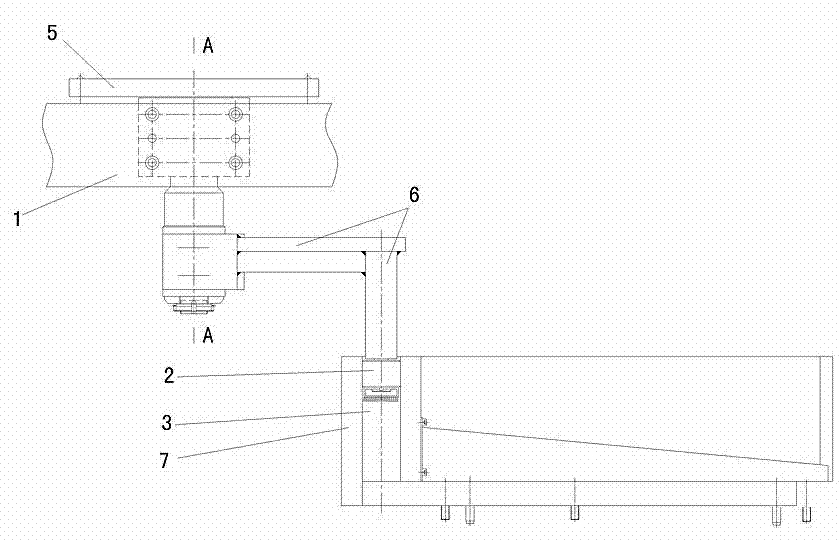

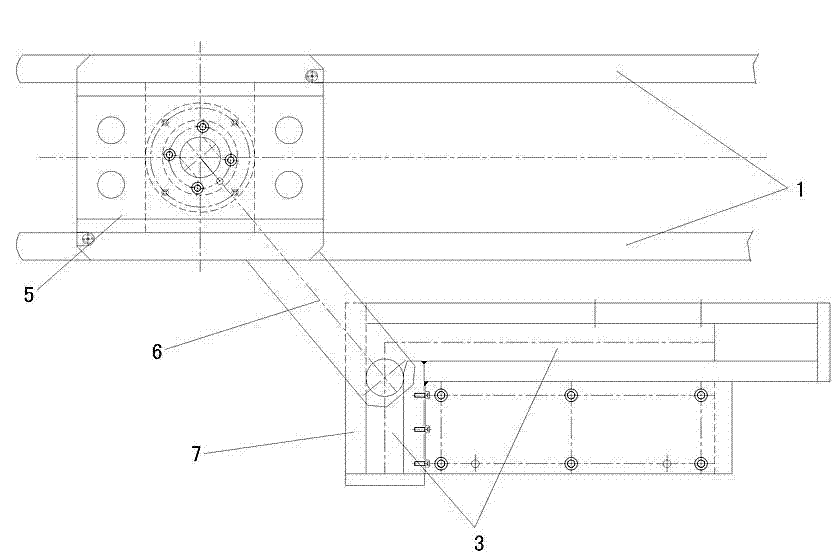

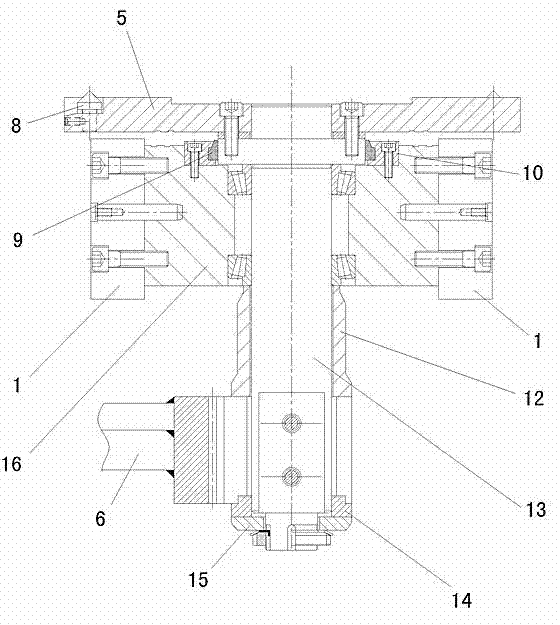

[0009] Such as figure 1 , 2 Shown: 1 is two band plates parallel to each other, 5 is the supporting plate 5 of the support workpiece with positioning pin 8. A connecting body 16 is fixed by bolts between the two strip plates 1, and a rotating shaft 13 is installed through a pair of bearings at the middle hole of the connecting body 16, and the upper end of the supporting disc 5 and the rotating shaft 13 is fixedly connected by bolts. The support disc 5 is located above the belt plate 1 .

[0010] A spacer 12 is sleeved on the rotating shaft 13 below the connecting body 16, and one end of the corner-shaped rotating arm 6 is fixedly sleeved on the lower end of the rotating shaft 13 and fixed by a retaining ring 14, a pressing plate 15 and a nut. The end of pivoting arm 6 is equipped with roller 2, and roller 2 is positioned at right-angle groove 3, and right-angle groove 3 is processed on the support 7.

[0011] A sealing ring 10 is fixed by bolts in the notch groove on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com